- Product Details

- {{item.text}}

Quick Details

-

Throat Depth (mm):

-

1400 mm

-

Width of Working Table (mm):

-

1400 mm

-

Dimension:

-

440cm*190cm*290cm

-

Place of Origin:

-

China

-

Brand Name:

-

Fangwei

-

Year:

-

2024

-

Weight (KG):

-

12000

-

Motor Power (kw):

-

18 kw

-

Marketing Type:

-

New Product 2024

-

Fastest bending speed:

-

0.2s/time

-

Conventional hinge cutter:

-

Option

-

Power hinge cutter:

-

Option

-

Rated voltage:

-

380V

-

Noise:

-

50 dB

-

Minimum inner dimensions:

-

140 mm*190 mm

-

Minimum material thickness:

-

0.35mm

-

Minimum inner size:

-

140mm

-

Number of axes:

-

Standard 13 axis concurrent linkage

-

Maximum bending thickness:

-

Optional thickness

Quick Details

-

Machine Type:

-

Synchronized

-

Length of Working Table (mm):

-

1400

-

Slider Stroke (mm):

-

170 mm

-

Throat Depth (mm):

-

1400 mm

-

Width of Working Table (mm):

-

1400 mm

-

Dimension:

-

440cm*190cm*290cm

-

Place of Origin:

-

China

-

Brand Name:

-

Fangwei

-

Year:

-

2024

-

Weight (KG):

-

12000

-

Motor Power (kw):

-

18 kw

-

Marketing Type:

-

New Product 2024

-

Fastest bending speed:

-

0.2s/time

-

Conventional hinge cutter:

-

Option

-

Power hinge cutter:

-

Option

-

Rated voltage:

-

380V

-

Noise:

-

50 dB

-

Minimum inner dimensions:

-

140 mm*190 mm

-

Minimum material thickness:

-

0.35mm

-

Minimum inner size:

-

140mm

-

Number of axes:

-

Standard 13 axis concurrent linkage

-

Maximum bending thickness:

-

Optional thickness

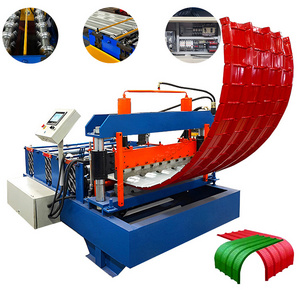

Sheet Bending Machine Metal Bending Machine Sheet Metal Bending Machine

The flexible bending center focuses on solving various complicated sheet metal and bending problems in metal forming. Through multi-axis concurrent linkage, sheet metal operations are automatically completed, and the dependence on molds and labor is resolved from a technical perspective, which effectively improves production efficiency and reduces production costs.

Easily realize the arc, press dead edge, back shape, closed shape and other complex sheet metal bending requirements.

The flexible bending center can be widely used in the field of steel cabinet shells (file cabinets, tool cabinets, outer shields, electrical cabinets, communication cabinets, gas cabinets, water meter cabinets...), kitchen utensils (refrigerators, air conditioners, stoves...) , Furniture, ventilation, refrigeration, purification, door industry, decoration, elevator and other related metal forming fields.

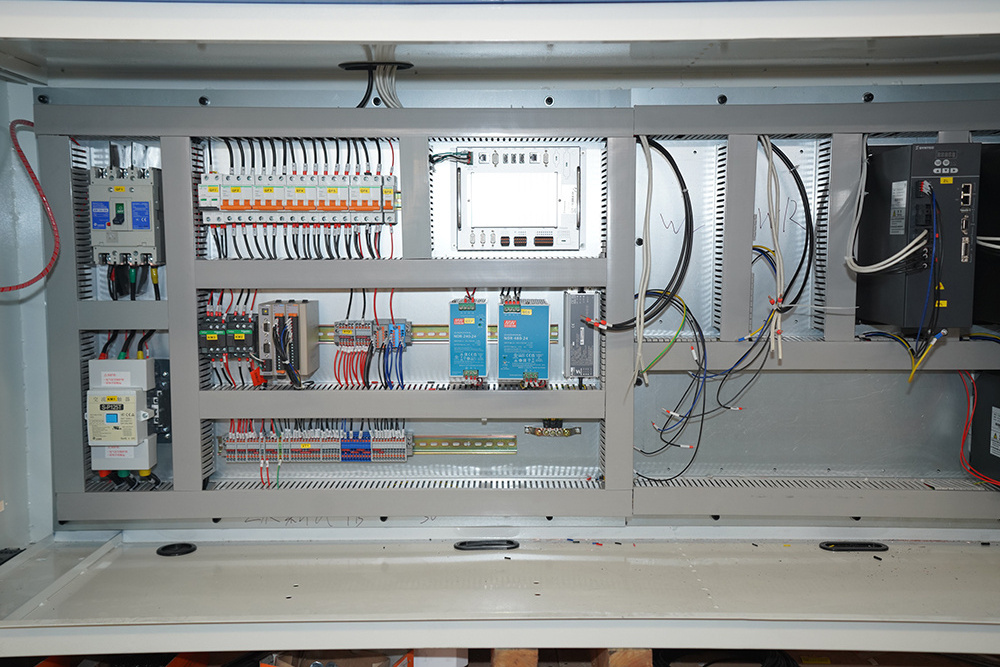

| Control system | Taiwan SYNTEC |

| Servo motor, drive | Taiwan SYNTEC |

| Cast body | AHXISIM Self-Developed |

| Welded body | AHXISIM Self-Developed |

| Feeding rack | AHXISIM Self-Developed |

| Reducer | Germany NEWGEAR |

| Screw rod | Taiwan HIWIN |

| Guide rail | Taiwan HIWIN |

| Bearing | Japan NACHI |

| Negative pressure pump | Zhejiang Tengyuan (Press arm type excluded) |

| Electrical parts | France Schneider |

| Grating ruler | Suzhou SINO |

| Hand wheel | Taiwan SYNTEC |

| Machine air conditioning | Tongfei Refrigeration |

| Pneumatic accessories | Taiwan AirTAC |

| Suction cup | AIRBEST (Press arm type excluded) |

| Coupling | Miki Pulley |

| Lubrication system | Guangdong Dingshen |

| Max. bending length (cm) | 320*150 |

| Max. bending height (mm) | 170/210 |

| Min. bending thickness (mm) | 0.15 |

| Min. four-sided forming size | 200*280mm |

| Single-sided forming | 150mm |

| Max. bending thickness (mm) |

Stainless steel 1.2

Cold plate 2.0 Aluminum plate 2.5 |

|

|

| Guide rail | Servo motor |

| Electrical parts | |

| Electrical parts | Hand wheel |

| Drive | |

| Grating ruler | Machine air conditioning |

| Reducer | Control system |

| Screw rod | Feeding rack |

| Suction cup | Oil pump |

| Bearing | Cast body |

Maanshan Fangwei Press Brake Tooling Co., Ltd. is located in Dahe mechanical equipment Industrial Park, Bowang Town, Bowang District, Ma'anshan City. It mainly produces sheet metal mechanical equipment. Its main products are as follows: bending center,handheld laser welding machine,press brake and other mechanical equipment and accessories. The products are widely used in sheet metal processing, decoration, metallurgy, shipbuilding, automobile, machinery, aviation and other professional production fields. With stable product quality and continuous growth, it is committed to becoming an advanced enterprise in the domestic medium and high-end sheet metal processing and forming machine tool industry.