- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Oudelong

-

Color:

-

Customizable

-

Core material:

-

Hard Polyurethane Foam

-

Advantage:

-

Fireproof

-

Thickness:

-

50/75/100/150/200mm

-

Type:

-

Machine Made

-

Features:

-

Thermal Insulation Waterproof Fireproof

-

Surface:

-

Prepainted

-

Length:

-

Customer's Choice

-

MOQ:

-

100 Square Meter

-

Use:

-

Wall Panel Board

Quick Details

-

Project Solution Capability:

-

Others

-

Application:

-

warehouse external wall insulation roof

-

Design Style:

-

Modern

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Oudelong

-

Color:

-

Customizable

-

Core material:

-

Hard Polyurethane Foam

-

Advantage:

-

Fireproof

-

Thickness:

-

50/75/100/150/200mm

-

Type:

-

Machine Made

-

Features:

-

Thermal Insulation Waterproof Fireproof

-

Surface:

-

Prepainted

-

Length:

-

Customer's Choice

-

MOQ:

-

100 Square Meter

-

Use:

-

Wall Panel Board

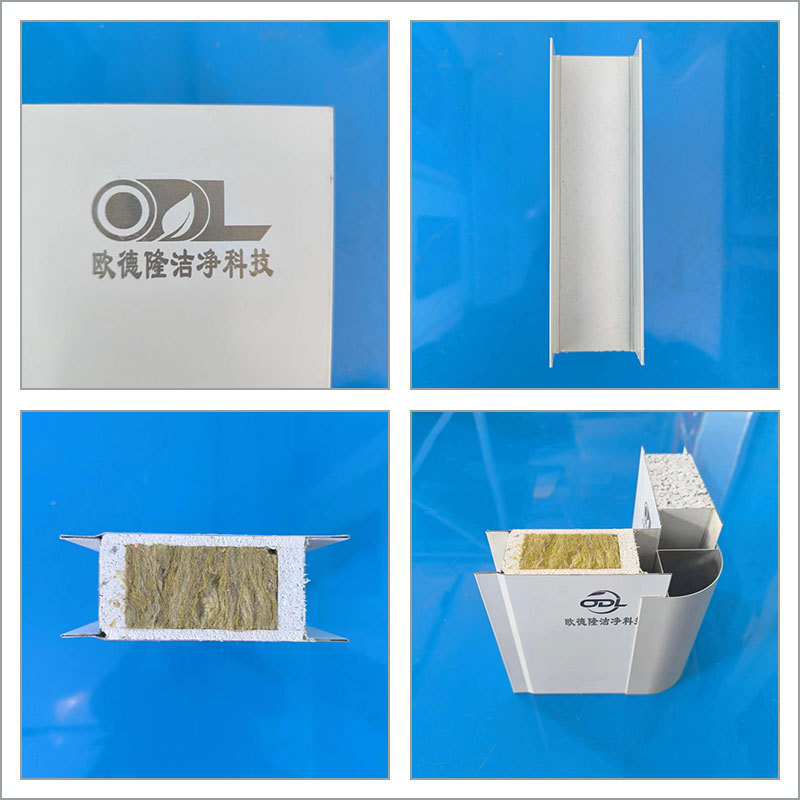

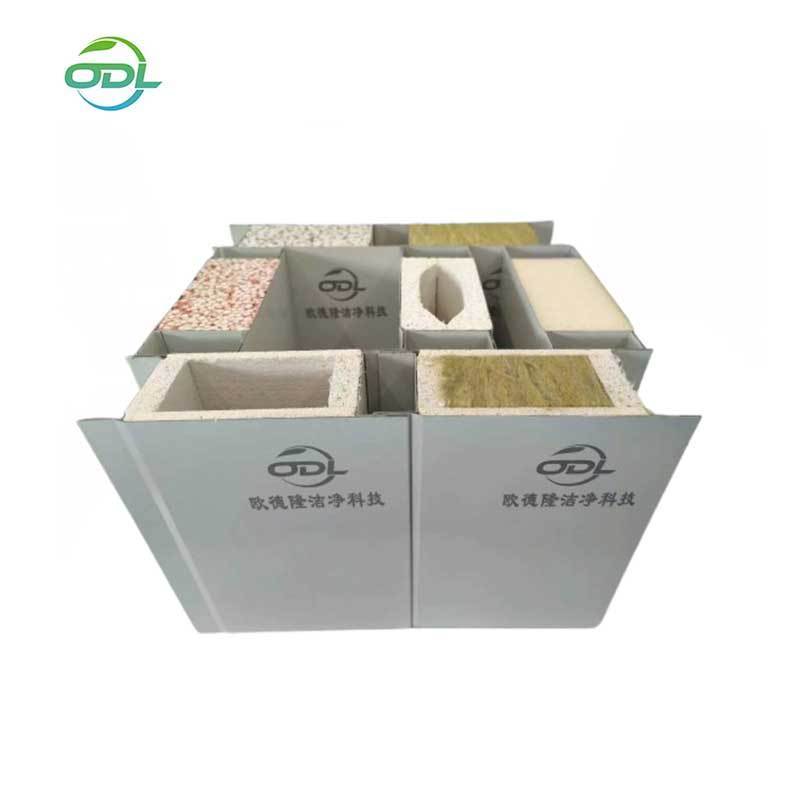

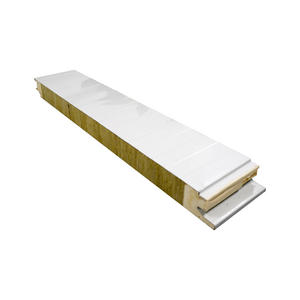

Product Paramenters

|

Product Name

|

Lightweight prefab house material 16mm 50mm 75mm polyurethane foam rock wool pu sandwich wall panel

|

|

Composition |

Surface:Al-Zn alloy coated steel sheet and high-quantity Nippon paint

Core:Rigid high-density polyurethane foam Bottom:Aluminium foil fiberglass cloth |

|

Design Style

|

Solid color, brick grain, stone grain, wood grain,Marbling or customized

|

|

Thickness

|

50, 75, 100, 150, 200mm or as customers requested

|

|

Width

|

950, 1150mm or as customers requested

|

|

Length

|

according to the project requirements and transportation conditions of fixed size

|

|

Weight

|

3.45-3.7kg/㎡

|

|

Fire-proof level

|

B level

|

|

OEM

|

Logo,partten and panel size

|

|

Warranty

|

10years

|

|

Advantages

|

Fire resistant,Waterproof,Thermal Insulation,Soundproof,Earthquake proof,Eco-friendly,Flame Retardant,Easy Installation.

|

|

Application

|

Hotel,Villa,Apartment,Building,Hospital,School,Mall,External,Internal,Ceiling,Roofing,Prefabricated House,Container House,Module

House. |

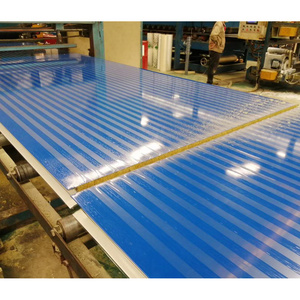

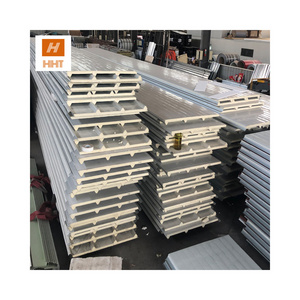

Products Description

Sandwich panel products are composed of two layers of molded metal panels (or other material panels) and a polymer insulating core that is directly pressed into the middle of the panels to be foamed and cooked into shape. The filling system also uses a closed cell molecular structure, which can eliminate the condensation of water vapor. The molding of the outer steel plate gives full consideration to the structure and strength requirements, and the inner surface layer is molded as a flat plate to meet various needs. Sandwich panels are beautiful in appearance, color and luster, overall effect is good, it sets load-bearing, heat preservation, fire prevention, waterproof in one, and no need for secondary decoration. It has a wide range of uses, especially for construction sites, temporary offices, warehouses, fences and so on. In the rapid installation and put into use, can be loaded and unloaded, the reuse index of the material, have obvious advantages, reduce the cost of temporary facilities on construction sites, is indispensable to the new lightweight construction materials.

Hot Searches