- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

500*500*500-2200*2300*1700mm

-

Weight:

-

266 KG

-

Marketing Type:

-

Hot Product 2021

-

Core Components:

-

main parts of machine

-

Application:

-

gold, copper , silver, chrome etc.

-

Color:

-

Customers' Requirements

-

Usage:

-

Mining Separation

-

Material:

-

Steel

-

After-sales Service Provided:

-

Online support,Field installation,Commissioning,training

Quick Details

-

Production Capacity:

-

High

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

Gelin

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

500*500*500-2200*2300*1700mm

-

Weight:

-

266 KG

-

Marketing Type:

-

Hot Product 2021

-

Core Components:

-

main parts of machine

-

Application:

-

gold, copper , silver, chrome etc.

-

Color:

-

Customers' Requirements

-

Usage:

-

Mining Separation

-

Material:

-

Steel

-

After-sales Service Provided:

-

Online support,Field installation,Commissioning,training

Products Description

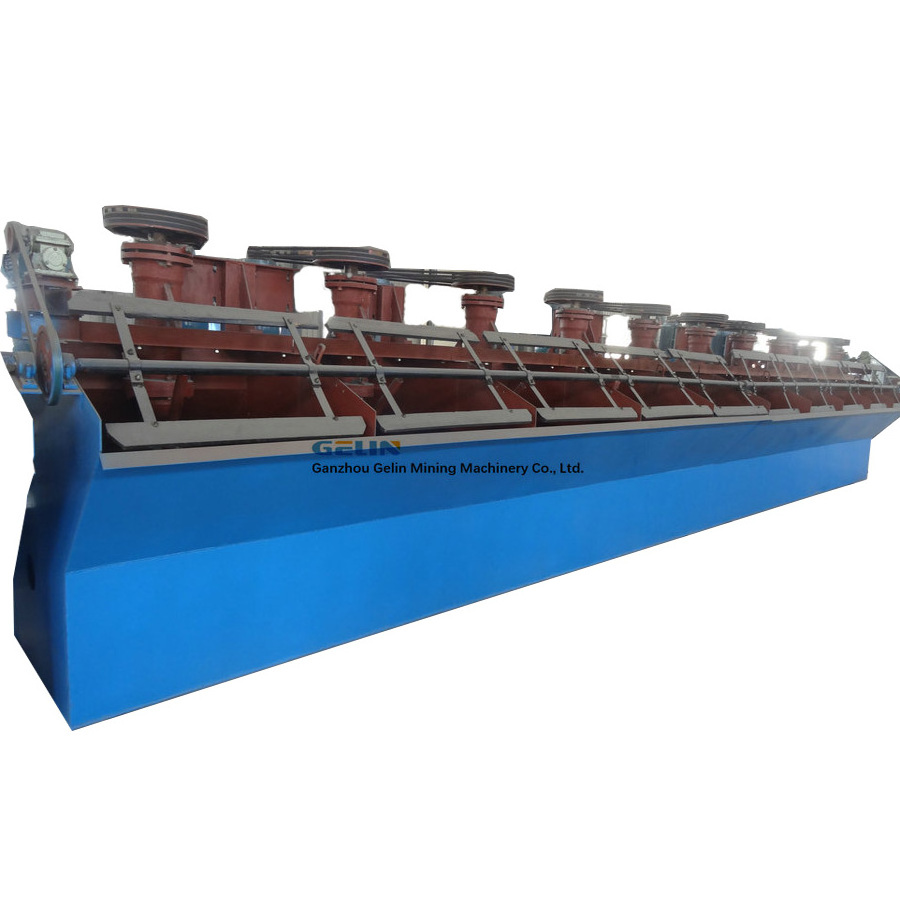

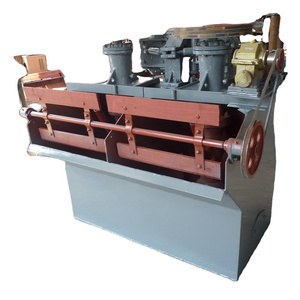

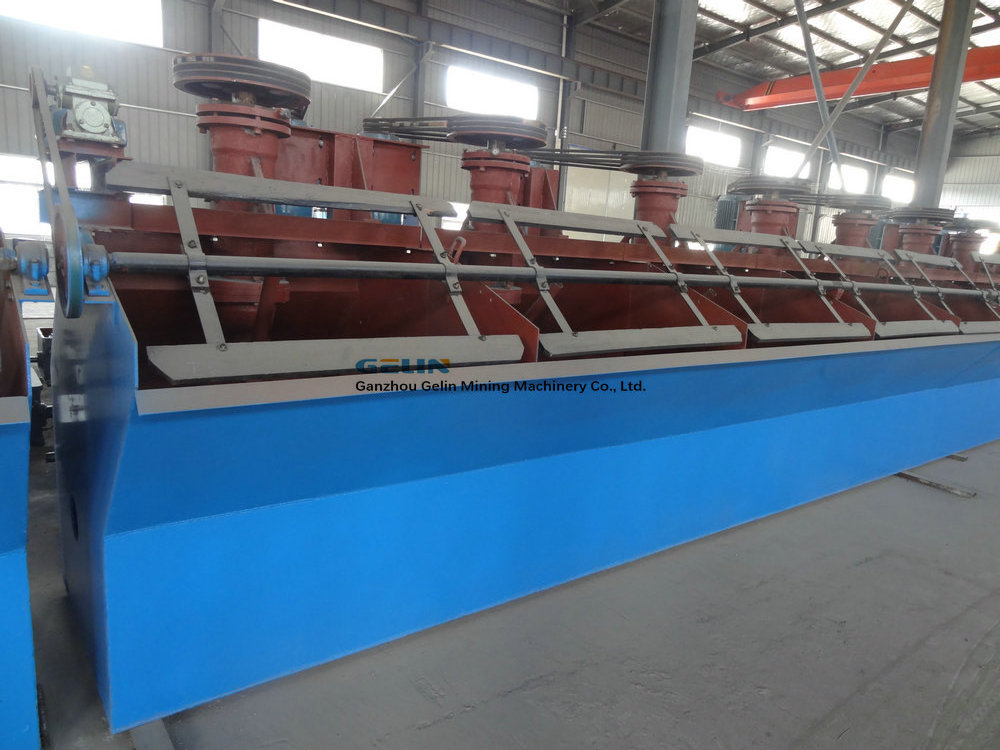

Ore Dressing Equipment Manufacturer Flotation Cell Separator For Copper Zinc Nickel Lead Zinc Graphite Recovery Line

Flotation machine

is the equipment to complete the flotation process, which is also called flotation cell. It is widely used for the rough, fine and reverse flotation operations of copper, lead, zinc, nickel, molybdenum and other non-ferrous metal, ferrous metal and nonmetal minerals. The types of flotation machine mainly include mechanical agitation flotation machine and froth agitation flotation machine.

Features

1. Large air suction volume, low power consumption;

2. Long service life of wear parts;

3.Each cell with air suction, slurry suction, flotation separation and flotation separation is easy to form flotation circle without any other accessory equipment, which is flexible to change process flow;

4. The rational slurry circulation minimizes coarse sand sediments which is conducive to flotation of coarse particle

5. Auto-control device of slurry volume contributes to flexible operating;

6. Backward type Impeller with upper and lower leaves, the upper blade generates upper circulation the lower blade generates lower circulation;

7. Mechanical stirring, self- air suction, self-slurry suction.

Working Principle

The impeller is rotated by V-belt of motor and produces negative pressure by centrifugal function. Enough air is sucked to mix slurry, and slurry mixes drug at the same time. Mineral sticks on bubble completely and floats on the surface of slurry to form mineralized bubble. Useful bubble is scraped out by adjusting flash-board height and controlling liquid surface.

The impellers and stators should be kept at a distance and should be changed when worn.The bearing in the pump should be maintained every three months.

|

1. Belt

|

7. Partition Plate

|

13.Air Inlet Pipe

|

19.Flotation Machine

|

|

2. Motor Wheel

|

8. Flashboard

|

14. Flotation Cel

|

20. Scraper Blade

|

|

3. Pulley

|

9. outlet

|

15.Guide Impe

|

21.Scraper Device

|

|

4. Bearing Seat

|

10. Discharge Hopper

|

16.Feeding Branch Pipe

|

22.Scraper Drive

|

|

5. Motor

|

11. Rotor

|

17.Feeding Pipe

|

|

|

6. Screw Lifter

|

12.Flotation Column

|

18.Branch Inlet

|

|

Product Parameter

|

Model

|

Volume (m3)

|

Cell size (mm)

|

Impeller Dia. (mm)

|

Impeller speed (r/min)

|

Capacity (m3/min)

|

Power (kw)

|

Singe cell weight (kg)

|

|

XJ-3

|

0.35

|

700× 700× 700

|

300

|

483

|

0.18-0.4

|

2.2/0.55

|

430

|

|

XJ-6

|

0.62

|

820× 900× 850

|

350

|

400

|

0.3-0.9

|

3/1.1

|

755

|

|

XJ-11

|

1.1

|

1100× 1100× 1000

|

500

|

330

|

0.6-1.6

|

5.5/1.1

|

1416

|

|

XJ-28

|

2.8

|

1750× 1600× 1100

|

600

|

280

|

1.5-3.5

|

11/1.1

|

2113

|

|

XJ-58

|

5.8

|

2200× 2200× 1200

|

750

|

240

|

3--7

|

22/1.5

|

3400

|

|

SF-0.37

|

0.37

|

700× 700× 750

|

296

|

386

|

0.2-0.4

|

1.5/0.55

|

468

|

|

SF-0.7

|

0.7

|

820× 900× 950

|

350

|

400

|

0.3-0.9

|

3/1.1

|

805

|

|

SF-1.2

|

1.2

|

1100× 1100× 1100

|

450

|

312

|

0.6-1.2

|

5.5/1.1

|

1373

|

|

SF-2.8

|

2.8

|

1700× 1600× 1150

|

550

|

268

|

1.5-3.5

|

11/1.5

|

2138

|

|

SF-4

|

4

|

1850× 2050× 1200

|

650

|

220

|

2--4

|

15/1.5

|

2582

|

|

SF-8

|

8

|

2200× 2900× 1400

|

760

|

191

|

4--8

|

30/1.5

|

4129

|

|

SF-10

|

10

|

2200× 2900× 1700

|

760

|

191

|

5--10

|

30/1.5

|

4486

|

|

SF-16

|

16

|

2850× 3800× 1700

|

760

|

191

|

5--16

|

30× 2/1.5

|

8320

|

|

SF-20

|

20

|

2850× 3800× 2000

|

760

|

191

|

5--20

|

30× 2/1.5

|

9828

|

Application&Successful Case

Packing & Delivery

Packing

Normally the machines are taken apart before delivery and are packed by suitable packing ways, the packing ways are as below:

1.

Nude packing.

2.

Bundle packing.

3.

Grass rope packing.

4.

Water proof packing.

5.

Wooden pallets packing.

6.

Wooden box or carton box packing.

Delivery

Usually the equipments are delivered aboard by

tracks,trains,or container(sea transportation). and some spare parts or very small goods also support to send by express

, our company have built good relationships with large cargo agent and shipping companies which guarantee our products delivered safely and promptly.Sea transportation includes three delivery ways as below:

1.

40HQ container

: used for goods without overlength, overheight and overweight;

2.

FR(Flat Rack) container

:suitable for large equipments with overlength,overheight like ball mill,excavator,etc.

3.

Bulk cargo shipment (LCL)

: used for some goods without loading in full container,normally it requires good packing with marks for safety and easy to be trackable.

About Company

Ganzhou Gelin Mining Machinery Co., Ltd

is an over 30 years professional

manufacturer and exporter of mining machinery for crushing, screening, grinding, flotation, separation etc. in China.

Gelin have a complete service system which can provide customer full service in mining field and after sales service.By now, Gelin’s equipments and services are exported to over 60 countries,include America, Russia, India, Africa, Brazil, Chile,South Africa,Zambia etc.

Sincerely welcome customers to visit our factory.

Our Services

One Stop solution for beneficiation plant service:

1.Engineering consulting available,it makes clients have a comprehensive understanding of beneficiation plant,including mine value,useful elements,mineral processing technology,plant scale,essential equipments,etc.

3.After reaching agreement with client,we start to engineering design,including planning,investigation,data collection, project evaluation etc. and then comes up with design scheme of beneficiation plant construction and working drawings.

2.Arrange mineral beneficiation experiment after received the material sample and beneficiation test report will be done after test.

3.After reaching agreement with client,we start to engineering design,including planning,investigation,data collection, project evaluation etc. and then comes up with design scheme of beneficiation plant construction and working drawings.

4.Manufacturing the necessary equipments and arrange the shipment.

5.Complete services for Installation and commissioning and technical training(operating training,common problem solving training).

After-sale Service

Regularly visit customers to provide after- sale

technical supports and to solve problems of beneficiation plant. For equipments supplied,we could provide one-year warranty and provide spare parts with preferential price in the long term and be responsible for any problems with the them.

FAQ

Q:

Are you a trading company or a factory?

A:

We are a factory at Shicheng county with 110 workers,6 workshops covered 17,000㎡ and office covered 2,500㎡. Welcome to visit our factory at anytime.

Q:

What is your payment terms?

A: By TT( Telegraphic Transfer ) , 100% or 40% Deposit before production and 60% balance payment will be paid off after sending product pictures and before loading from factory.

A: By TT( Telegraphic Transfer ) , 100% or 40% Deposit before production and 60% balance payment will be paid off after sending product pictures and before loading from factory.

Q: How long is the guarantee period of your products?

A:

The guarantee period is 1-2 years, pls ask staff for more details. And we will supply lifelong technical support service and the spare parts at lowest cost.

Q:

Is it possible to produce customized products

?

A: Yes, most of our products are produced as required.

A: Yes, most of our products are produced as required.

Q:

Is it possible to provide sample for your factory to do ore-dressing experiment?

A: Yes, engineering consulting is available and we’d like to arrange mineral beneficiation experiment after received your sample and provide the test report.

A: Yes, engineering consulting is available and we’d like to arrange mineral beneficiation experiment after received your sample and provide the test report.

For more details, please refer to our website:

www.gelinmachinery.com

Related Products

Hot Searches