- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

9.167m*9.167m*19.48m

-

Weight:

-

20000 KG

-

Product Name:

-

Customized 1000 Tons Grain Storage Silo with Solid Silo Structure

-

Certification:

-

ISO9001/ISO14001/OHSAS18001

-

Dimension:

-

According To The Capacity

-

Capacity:

-

100-3000T

-

Bottom Type:

-

Flat/Hopper

-

Grain Silo Service Life:

-

25-30 Years

-

Name:

-

vertical maize silo

Quick Details

-

Core Components:

-

Steel Plate

-

Place of Origin:

-

Henan, China, Henan, China

-

Brand Name:

-

HKB, HKB

-

Dimension(L*W*H):

-

9.167m*9.167m*19.48m

-

Weight:

-

20000 KG

-

Product Name:

-

Customized 1000 Tons Grain Storage Silo with Solid Silo Structure

-

Certification:

-

ISO9001/ISO14001/OHSAS18001

-

Dimension:

-

According To The Capacity

-

Capacity:

-

100-3000T

-

Bottom Type:

-

Flat/Hopper

-

Grain Silo Service Life:

-

25-30 Years

-

Name:

-

vertical maize silo

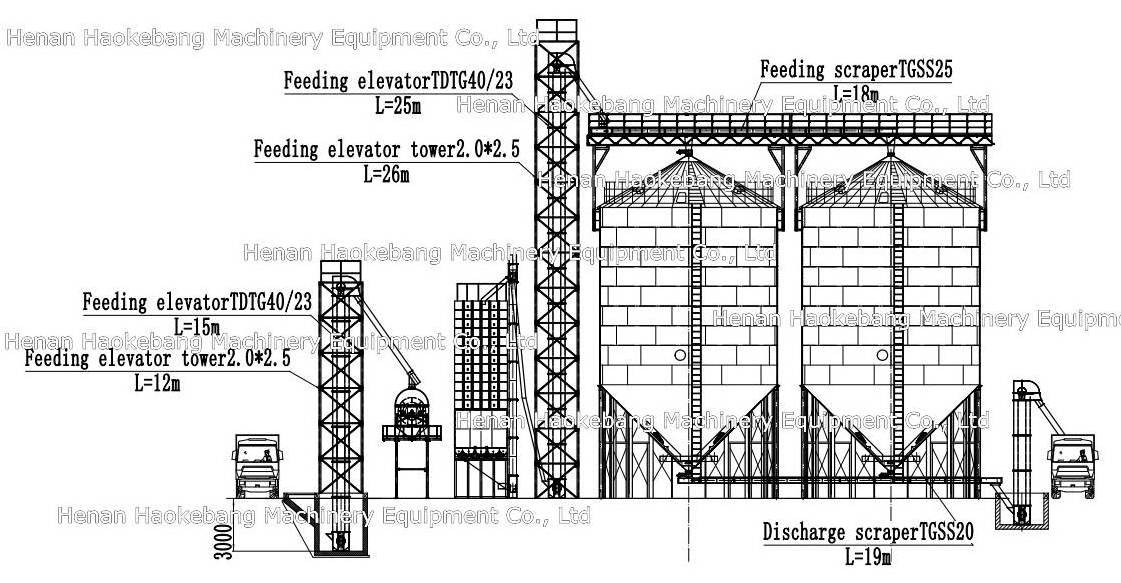

Customized 1000 Tons Grain Storage Silo with Solid Silo Structure

| Product Description |

As the name implies, grain silo is for storing grain. The selection of grain silo should be conducive to food security storage, be advanced to a certain extent, be conducive to the realization of mechanization,and be suitable for the implementation of advanced grain storage technology.

Application

HKB Grain Silo is widely used for grains storage such as wheat, corn, soybean, paddy, rice, soybean meal, barley, malt, sunflower seeds, rapeseeds, peanuts, flour, and other powder materials, oat, special grain, and seeds, etc.

Feature

1. Assembly, easy to ship and save freight.

2.Hot-dip galvanized plates (275g/m2-600g/m2), very WATERPROOF &RUST-PROOF.

3. Hopper bottom has a low-cost price.

4. Flat bottom has a large capacity from 1500T-20000T.

5. Silos can store grain safely and save labor costs and space.

Technical Parameter

| 1000 Ton 45° Hopper Bottom Steel Silo Technical Parameter | |||||

| Project | Layer Number | V(m³) | C(t) | Dia(m) | H(m) |

| TCZK10013 | 13 | 1379 | 1034 | 10.084 | 23.61 |

| TCZK11010 | 10 | 1346 | 1009 | 11.000 | 20.95 |

| TCZK11909 | 9 | 1481 | 1111 | 11.917 | 20.55 |

| TCZK12809 | 9 | 1749 | 1312 | 12.834 | 21.27 |

| Contact us for more specifications | |||||

Professional team to answer your questions online

|

Deatails |

|

The roof beam is made of C-shaped steel, the upper part is connected with the tio ring of the silo, the lower part is connected with the pillar of the silo,and the beam is horizontally connected by angle steel to form the framework of the silo top. |

|

The coaming of the silo is made of 275g/m2 galvanized steel plate. The coaming is gradually thicjened from top to bottom according to the stress of each layer. |

|

Accessory Equipment |

|

Ventulation System Including fan and out ring air suxt, inner air duct, silo top induced draft fan and natural ventulation window auciliary ventilation, which can take the maximum amount of indoor heat and ensure the quality of grain. |

|

|

Clean up the system Cylinder promary cleaning screen Long screen body, goog cleaning effect. Fully enclosed frame, good sealing and dust proof performance. Small power, high output, stable and reliable operation. Self balancing vibrating screen Adiopt cibration motor, vibration damping rubber sprong and other preferred parts, with low noise and stable operation. |

|

|

Temperature measurement system The temperature measuring cable is suspended on the temperature measuring beam of the silo top framework, and the temperature sensors are distributed on the electricityon the cable. |

|

|

Dedusting system In the process of grain circulation and cleaning, there will be a lot of dust, which is not conducive to the quality of grain, further processing and encironmental sanitation. Dust remocal equipment can effectivel quppress dust. |

|

|

Fumigation system The generator delivers the drug gas to the silo through the pipeline, and the upper opening of the silo wall is connected with the pipeline back to the generator to form a circulation in the silo. |

| Case |

|

Our Service |

Pre-sale:

- Selection of equipment model.

- Design and manufacture products according to the special requirements of customers.

- Train technical staff for customers.

- The company sends engineering and technical personnel to the user's site to plan the site and design the best process and scheme for free.

On sale:

- Product acceptance.

- Assist clients in drawing up construction plans.

After sale:

- Assign special after-sales service personnel free of charge and arrive at the scene to guide customers to install and debug.

- Equipment installation and commissioning.

- On-site training operators.

- After the complete set of equipment is installed, the full-time technical staff will assist the customer to smoothly produce on-site for free until the user is satisfied.

| Related Products |

China 2000tons Rice Filling Machine Wheat Corn Suction China Hot Sale

Corn Maize Steel Silo Packing Machine Machine Grain Dryer