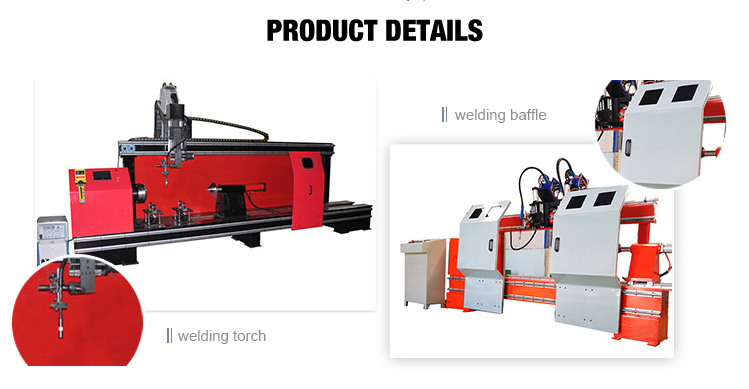

Hydraulic cylinder circumferential welding equipment is mainly used for girth weld of hydraulic cylinder and piston rod automatic multi-layer swing welding; the structure is horizontal bed type. According to the actual needs of users, it can be single or double torch welding, welding head axial movement is driven by servo motor. In order to adapt to different length of work piece, tailstock moving using manual and pneumatic jacking.

Weld appearance beautiful, uniform, penetration, weld width meets the requirements. Welding operation simple and flexible; work piece clamping convenient; reliable performance, convenient loading and unloading. high degree of automation, low labor intensity of workers.