- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

45kw

-

Dimension(L*W*H):

-

4*3*2M

-

Weight (KG):

-

6500

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Similar to diamond film:

-

Chemical vapor deposition

Quick Details

-

Machine Type:

-

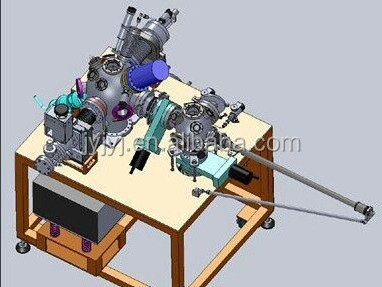

CVD vacuum coating machine, Spray Booths, Painting Equipment, Plc Controller Programmable Logic Controller, Pre-treatment Equipment, Conveying Equipment, Curing oven, Coating Equipment, Anodized Equipment, Sandblasting Machine, Other

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Junying

-

Voltage:

-

380V

-

Power:

-

45kw

-

Dimension(L*W*H):

-

4*3*2M

-

Weight (KG):

-

6500

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Similar to diamond film:

-

Chemical vapor deposition

Small Diamond Like Carbon DLC super hard film vacuum coating plating machine / black color vacuum coating machine

The main properties of DLC films

1) Mechanical Properties

a. hardness and elastic modulus. DLC film hardness and elastic modulus of the differences in the deposition method is large, can be prepared to meet or exceed the hardness of diamond DLC films [10] with a magnetic filtered cathodic arc method, Guangzhou Nonferrous Metal Research Institute prepared by cathodic arc DLC film above the maximum hardness up to 50GPa, and the ion source in conjunction with unbalanced magnetron sputtered DLC film hardness of 21GPa [11]. Components of the film within a certain influence on the hardness of the film, the incorporation of Si, N may increase the hardness of the DLC film. DLC film has a high elastic modulus, though lower than diamond (1100GPa), but higher than the modulus of elasticity of metal and ceramic in general.

b. stress and bonding strength. And bonding strength of the film stress of the film is to determine the stability and service life, two important factors affecting the properties of the film, combined with low stress and high strength of the DLC film is easy to crack, wrinkle in the application, or even fall off, so the preparation the DLC film is preferably a moderate compressive stress and high bonding strength. Most studies indicate that the direct deposition on the substrate film DLC film / substrate is generally low bonding strength, improve the binding of Guangzhou Institute for Nonferrous Metals DLC film and the substrate by using the Ti / TiN / TiCN / TiC intermediate graded transition layer strength, DLC films deposited on the mold strength of the steel combined with 44N-74N [12], the overall thickness of the film prepared in the guide up to 5 m.

2) friction properties

DLC film not only has excellent abrasion resistance, and has a low friction coefficient, below 0.2, is an excellent anti-wear surface modified membrane. DLC friction coefficient varies with the type and composition of the film preparation process of change, the lowest coefficient of friction of up to 0.005 [13]. Doped metal element may reduce the coefficient of friction, but can be added to improve the lubrication H environment have some influence on the coefficient of friction. But in general, DLC films with traditional rigid film (as described above TiN, TiC, TiAlN, etc.), has obvious advantages in terms of friction coefficient, the coefficient of friction of conventional rigid films are above 0.4. This country, DLC films may replace the dura mater in many of these traditional field of tribology. Metal-doped DLC films prepared Guangzhou Nonferrous Metal Research Institute has good resistance to friction and wear properties and low friction coefficient of 0.13-0.15 [14].

3) Thermal Stability

Because DLC is a metastable materials, poor thermal stability is an important factor limiting the application of DLC films at 300? Appears the sp3 to sp2 key shift key when C above annealing, for a lot of people trying to improve work thermal stability. Studies have found that: Si is added can significantly improve the thermal stability of the DLC film containing 20 at% Si-DLC film annealed at 740 C occurs when the sp3 to sp2 bond transformation [15]. Similarly, a metal (such as Ti, W, Cr) may also be incorporated to improve the thermal stability of the DLC film, in this respect we are studied.

4) Corrosion resistance

Pure DLC film having excellent corrosion resistance, various types of acids, bases or aqua regia is very difficult to corrode it. However, the corrosion resistance of the DLC film is doped with other elements decrease, which is due to the erosion of the first doping element, so as to destroy the continuity of the film caused.

5) Surface Condition

Generally more DLC film surface is smooth, there is no significant influence on the surface finish of the substrate, but as the film thickness increases, the surface roughness decreases. DLC film surface finish obtained by different deposition methods is different, Guangzhou Institute for Nonferrous Metals deposited by ion source quality is better than the surface of the DLC film by arc ion plating.

DLC film having good blocking resistance, especially for non-ferrous metals (such as copper, aluminum, zinc, etc.), plastic, rubber, ceramics, also has anti-adhesive properties.

DLC films used in the field of mechanical function

(1) Drills, milling cutters

DLC films can be applied to the drill bit and cutter, especially the metal doped DLC film, which not only has high hardness, but also has a low coefficient of friction, anti-adhesive non-ferrous metals. Metal-doped DLC layer Hauzer Dutch company prepared for the cutting of high strength aluminum alloy, the surface can reduce the chip called tumor (BUE). The result is extended life of the tool and to the workpiece material in the cutting surface is smooth. Especially in dry machining and deep processing, film performance is very good [16]. Nonferrous Metal Research Institute in Guangzhou also plated on the cutter TiAlN + DLC film during processing significantly improve the life of non-ferrous metals and processing quality.

(2) CD and auxiliary mold mold

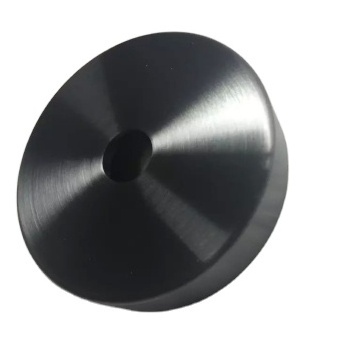

Mold is an important tool for the production of discs CD, CDR, DVD's, in order to reduce its friction with the base plate (nickel plate), and I hope the mold surface is hard and low coefficient of friction, at present, they use a DLC film abroad, greatly improving the life of the mold and the quality of the disk. DLC films we have begun preparing for the field, and has been successful. Figure 2 DLC layer disc mold Guangzhou Nonferrous Metal Research Institute prepared benevolence, their life has reached more than two million times to open the closed (uncoated mold only 50 million times around) [17]. Meanwhile DLC film coated on its secondary mold has reached its life supporting the use requirements.

After the coating has high hardness, low coefficient of friction, wear and corrosion resistance, good adhesion and environmental protection features.

Auxiliary tray mold die

(3) the mandrel

DLC film friction wear and corrosion resistance, can significantly improve the performance and life of the gear, shaft and other moving parts. Figure 3 DLC film mandrel Guangzhou Nonferrous Metal Research Institute prepared to extend its life by more than three times the corrosion resistance increased by more than 4 times.

Application on the blade (4)

DLC is now also a variety of applications on blades of scissors, razors and other such. DLC film decreases friction with the skin of the blade, improving the performance of the blade, extending the service life. Figure 4 shows the development of the Guangzhou Institute of Nonferrous Metal DLC films barber scissors tablets using DLC film superior friction properties, significantly improved blade life, especially after reducing surface friction coefficient, reduce noise, very popular with users.

On the application of key components (5)

DLC films can also play many of the key components of its excellent performance, such as in the application of Stirling made on the piston (Figure 5) with its low coefficient of friction, reduce friction, improve wear resistance , to no oil lubrication and service life requirements.

DLC films deposited on the hook (Figure 6) to replace the original hard chrome plating, not only to avoid the problem of environmental pollution, and significantly improve the surface hardness and wear resistance, service life increased more than 10 times - in Sewing Accessories noise, but also because of the lower coefficient of friction surface of the film, produced during the operation of the machine becomes small.

(6) Other Applications

DLC films used in the tool and die very many other examples, such as: powder metallurgy mold, plastic mold, lead frame bending mold, glass mold, mold machining magnesium alloys in the bearings.

These are the details of diamond-like carbon coating (DLC) film on a hard piece of special applications, including diamond-like coating (DLC) film on a rigid application of a special piece of prices, models, pictures, manufacturers and other information!

FeaturesThe equipment used-doped Tin surface of the technology, the formation of ion film, a very good wear resistance,widely used in various upmarket decorative coatings.

Best regards; Looking forward to your reply!

Wechat: nbjunying