- Product Details

- {{item.text}}

Quick Details

-

Appearance:

-

white elastomer

-

viscosity:

-

thixotropic

-

Thermal Conductivity:

-

1.2

-

Application:

-

Sealing/Bonding

-

Fields:

-

LED ceiling light/LED tube

-

Packing:

-

45g/tube, 100tube/carton

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

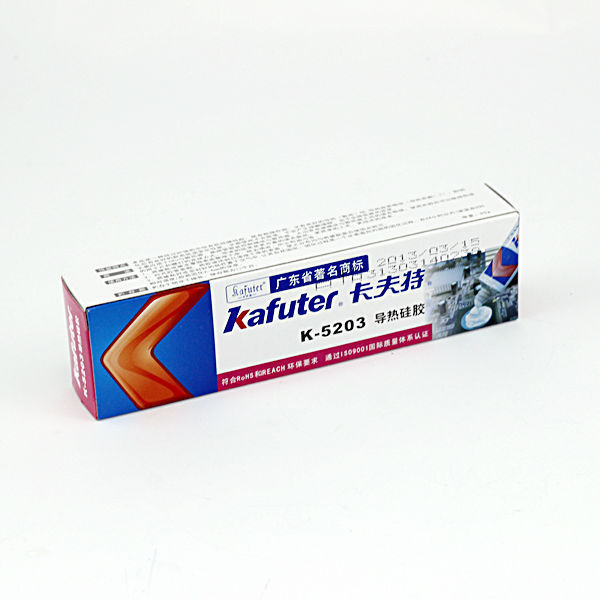

-

kafuter

-

Model Number:

-

5203

-

Appearance:

-

white elastomer

-

viscosity:

-

thixotropic

-

Thermal Conductivity:

-

1.2

-

Application:

-

Sealing/Bonding

-

Fields:

-

LED ceiling light/LED tube

-

Packing:

-

45g/tube, 100tube/carton

Kafuter K-5203 electronic electrical insulation silicone sealant

(Seal in LED lights, CPU, Radiator)

FEATURES

K-5203 is a reinforced thermally conductive silicone elastomer with great adhesion, insulation and dissipation.

(1) one part, room cure, white thixotropic elastomer .

(2) Excellent in cold and high alternating resistance (-60°c~ 280°c).

(3) No peeling and good disassemble after long time usage.

(4)The elastomer with high bonding strength , the shear strength is 30kg/cm 3

APPLICATION

fill, bond, and seal in electronics

1. the gap between CPU and radiators

2. the gap between thyristor control modules and radiator

3. the filling of high-power electronics modules and radiators,etc.

TYPICAL PROPERTIES

|

Cured |

Property Name |

K-5203 |

|

|

Appearance |

white |

||

|

Viscosity ( cp ) |

thixotropic elastomer |

||

|

Density(g/c m 3 ) |

2.0~2.5 |

||

|

Initial Curing Time(25°c , min) |

≤30 |

||

|

Uncured |

Mechanical Properties |

Tensile Strength (Mpa) |

≥2.5 |

|

Elongation At Break (%) |

≥100 |

||

|

Shear Strength (Mpa) |

≥1.5 |

||

|

Hardness(shore A) |

50~65 |

||

|

Working Temp (°c ) |

-60~280 |

||

|

Electrical Properties |

Dielectric Strength(kv/mm) |

≥18 |

|

|

Permittivity (@60Hz) |

2.8 |

||

|

Volume Resistivity (Ω.cm) |

1×10 15 |

||

|

Thermal Conductivity(w/m.k) |

1.2 |

||

HOW TO USE

Preparation

Clean the surfaces by removing the rust, ash, and oil, etc.

Application

Pierce the opening with the tip of the cap. Fix the nozzle, and coat the clean surface evenly with the adhesives, then bond the two surfaces.

Cure Condition

The elastomer get cure with the depth of 2~4mm in 24 hours (at room temperature, 55% moisture). if the bonded parts is too deep (especially the parts not easy to contact with air) or the temperature is too low, the full cure time will be extend.

Advise users prepare enough time to let elastomer get full cure in order to keep the properties stably.

ATTENTION

1. After the application, screw its nozzle tightly and store in dry and cool place for next time using.

2. There may be some cured gel around the opening when you use it again, just remove the cured, and use the uncured.

PACKAGING

45 g/ tube

STORAGE

Store in cool and dry place, the shelf life is 12 months (≤25°c )