- Product Details

- {{item.text}}

Quick Details

-

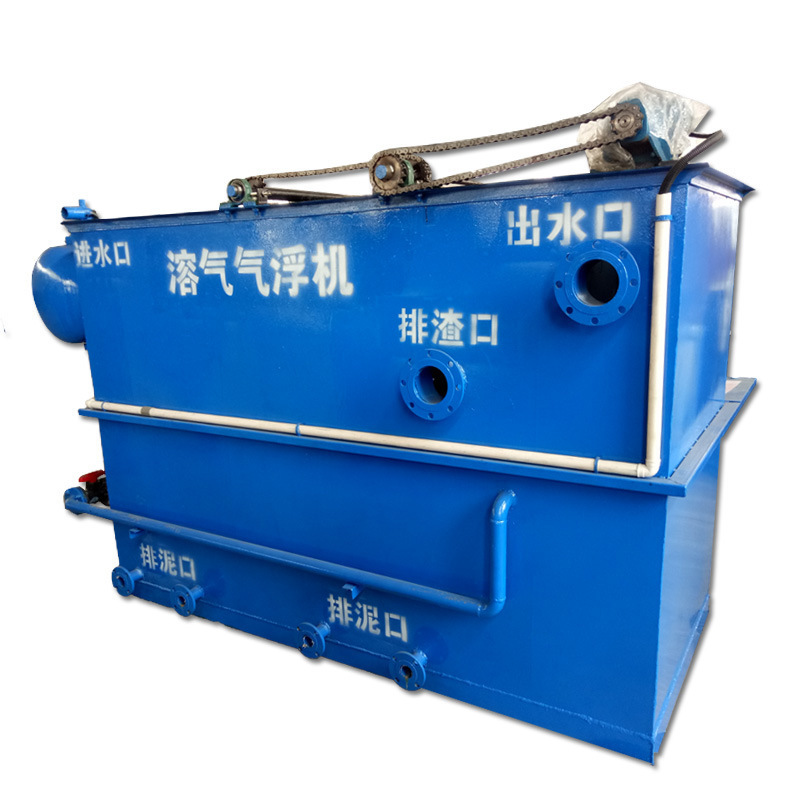

pump:

-

1 set

-

air blower:

-

0.55kw

-

capacity:

-

1m3/h

Quick Details

-

Place of Origin:

-

China

-

After-sales Service Provided:

-

Video technical support

-

material:

-

carbon steel

-

pump:

-

1 set

-

air blower:

-

0.55kw

-

capacity:

-

1m3/h

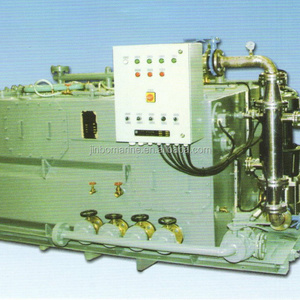

marine sewage treatment plant

marine sewage treatment plant

Description

Membrane Bioreactor (MBR) is a kind of advanced technology developed since the end of 20th century which realized the efficient combination of membrane separation technology with biological technology. The membrane separation technology replaces the traditional active sludge method and the normal filter unit, its strong separation ability can make the SS turbidity near to be zero. Hydraulic retention time (HRT) sludge age (SRT) is completely separated, the outlet water is good and stable in quality, it can be reused without the third level treatment. Due to the high security and economic and effective water, it greatly expands the scope of application of waste water recycling.

Benefits of Mbr Sewage Treatment Plant

1.Excellent water quality

Complete separation with BOD, SS, produce to permeated water for reuse.

Removes suspended solids by filtration rather than settling, the process is much more effective than conventional treatments and can operate at much higher mixed liquor suspended solids (MLSS) concentrations.

2.Small footprint

MBR is an activated sludge reactor system that utilizes a single complete mix reactor in which all the steps of the activated sludge process occur with a membrane filter system submerged in the reactor. Easy to modify existing facilities. It will save area and cost effectively.

3.Simple process and Easy maintenance

Simply MBR system process will make easy maintenance, and reducing man power ,operating costs and energy savings.

Mbr Sewage Treatment Plant Applications:

1.Sewage wastewater treatment

2.Municipal and commercial biological waste water

3.Livestock wastewater

4.Organic wastewater

Mbr Sewage Treatment Plant is consist of two parts which is element block and aeration block. The element block has a number of membranes stacked together with equal distance and each flat sheet membranes attached on both side of spacer and this element is connected with tube to permeated water header to produce permeated water for reuse.

1.Consistent and Excellent effluent water quality

Using membrane to separate sludge and retain activated sludge at high Concentration to removing BOD, SS and fecal coliform, therefore treated water is suitable for beneficial reuse

2.High Flux, Low fouling of membrane material

Using polyethersulfone(PES) material of membrane and it contains more hydrophilic property than other brand membrane to produce high quality of treated water. Also it has low contact angle and evenly distribute the pore sizes.

3.Better design of membrane(flat sheet)

No sludge tangled on the surface because its flat and cleaning by upward water by air diffuser and no breaking and surface blocking near the ends of membrane because its flat sheet membrane.- Easy maintenance & Control

Maintain high MLSS to reduce activated sludge tank and it will not Depend on influent water quality to produce stable permeated water also sludge is separated by membrane to produce compact size of area and easy maintenance.

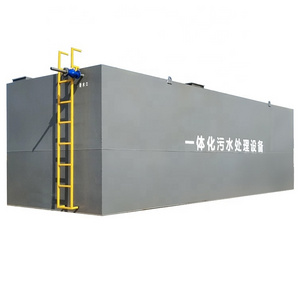

| Item | Z-1 | Z-3 | Z-5 | Z-7.5 | Z-10 | Z-15 | Z-20 | Z-30 | Z-40 | Z-50 |

| Treating capacity(m 3 /h) | 1 | 3 | 5 | 7.5 | 10 | 15 | 20 | 30 | 40 | 50 |

| No. of machine parts | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 3 | 4 | 4 |

| Sludge absorption and primary sedimentation tank | 1.8 | 5.5 | 9 | 14 | 18 | 27 | 36 | 50 | 82 | 100 |

| Contact oxidtion Mond(m 3 ) | 5.0 | 14.5 | 24 | 36 | 44 | 63 | 83 | 130 | 170 | 200 |

| Surface load secondary sedimentation tank(m 3 /h) | 1.2 | 1.3 | 1.3 | 1.3 | 1.2 | 1.2 | 1.5 | 1.5 | 1.5 | 1.6 |

| Disinfection tank(m 3 ) | 0.6 | 1.8 | 2.8 | 4 | 5.5 | 8 | 10 | 15 | 20 | 25 |

| Weight of biggest part(t) | 5 | 6 | 7 | 10 | 8 | 10 | 10.5 | 10.5 | 10.5 | 12 |

| Total weight(t) | 5.5 | 6.5 | 8 | 11 | 17 | 20 | 21 | 29 | 38 | 42 |

| Occupy area(m 2 ) | 6 | 14 | 20 | 30 | 50 | 65 | 75 | 115 | 155 | 185 |

12 Flange ming Machine

Packaging of sausage filling machine

One or two sets can be delivered by air or international express.

Shipping

We have been cooperating with several large transport agents and shipping

companies for long terms, the machines will be transported to you safety and

timely.

Delivery time

Normally, 5-7 days for preparing after receive your payment.

We will help confirm if we have machine in stock.

3.Any problems occur while using, professional advice will be given by us.

4.Can supply other meat machine and so on.