- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V Customized

-

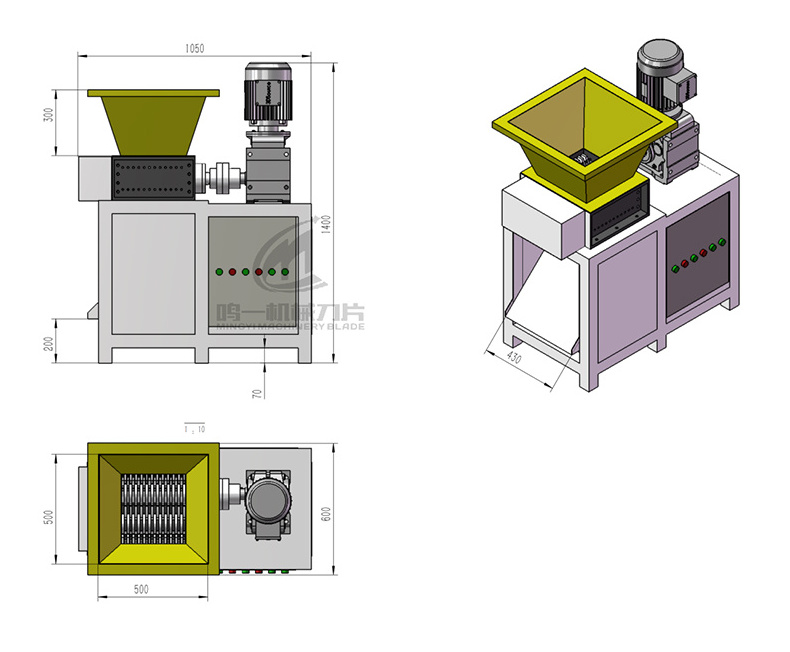

Dimension(L*W*H):

-

1060*600*1400

-

Power (kW):

-

3

-

Weight (T):

-

0.45

-

Product name:

-

Mini Shredder Machine

-

Capacity:

-

300-400kg/h

-

Blades material:

-

9SiCr/D2/SKD-11/ Customized

-

Motor power:

-

3KW

-

Crush chamber:

-

500*500*300MM

-

MOQ:

-

1 set

-

Blade quantity:

-

24pcs

-

Blade size:

-

180*12

-

Weight:

-

450kg

-

Package size:

-

1150*760*1640mm

Quick Details

-

Max.Production Capacity (kg/h):

-

400

-

Place of Origin:

-

Jiangsu, China

-

Production Capacity (kg/h):

-

300 - 400 kg/h

-

Voltage:

-

220V/380V Customized

-

Dimension(L*W*H):

-

1060*600*1400

-

Power (kW):

-

3

-

Weight (T):

-

0.45

-

Product name:

-

Mini Shredder Machine

-

Capacity:

-

300-400kg/h

-

Blades material:

-

9SiCr/D2/SKD-11/ Customized

-

Motor power:

-

3KW

-

Crush chamber:

-

500*500*300MM

-

MOQ:

-

1 set

-

Blade quantity:

-

24pcs

-

Blade size:

-

180*12

-

Weight:

-

450kg

-

Package size:

-

1150*760*1640mm

Double shaft shredder also called cutting shredder through cutting and extrusion to reduce the material size,widely used in the waste plastic,scrape rubber,scrap metal,wood,garbage and other large volume of waste.our company provide shredding machine equipment with mature technology,advanced design and reliable quality to crush and reduce volume before waste recycling.This double shredding machine by the PLC automatic control,with which has start, stop,reverse and automatic reverse in overload condition

Features:

1.Low noise, less dust with high capacity.

2.Special thick plate precision machining combination frame, large angle hexagonal column of the strong rotation axis, large diameter solid into the hopper, so you can safely put into large raw materials.

3. In the thickness, shape, arrangement and other aspects of the design and processing of a unique rotary knife, shear strong, sharp blade, can be highly efficient broken.

4. Unique multiple combination sealing structure effectively blocks the contact of broken material and grease.

5. The moving blade material is made of special alloy tool steel forging blanks, precision machining, multiple heat treatments and low temperature freezing heat treatment technology.

|

Model

|

MY-300

|

|

Motor

|

3kw-4, 220v,50Hz (Customized)

|

|

Reducer

|

JL2#-16

|

|

Blade size

|

φ180*12

|

|

Blade quantity

|

24pcs

|

|

Weight

|

About 450kg

|

Note: The above is a reference value. The specific situation depends on the material to be processed, and the processing capacity will be different for different materials. We will design a suitable model according to your needs.

Nanjing mingyi machinery blade Co., Ltd is located at the junction of Jiangsu and Anhui provinces and 20 kilometers away from Nanjing Lukou Airport. The company is an enterprise specializing in the production of industrial blades and CNC molds. We rely on years of experience in professional knife making and mold making, and provide knifes and molds that meet the requirements of customers according to their different needs. Widely used in printing, papermaking, carton, forestry, metallurgy, rubber, plastics, food, textile, electrical appliances, light industry and other punching and shearing industries.

Material guarantee: In order to ensure product quality, the company has medium carbon steel, high carbon steel, alloy steel, tool steel, high speed steel, tungsten steel for customer demand order, and the spectrometer is used to detect whether the material is correct.

Hardness guarantee: Only by mastering the heat treatment by oneself can the tool reach its best effect and highlight the soul of the tool, and heat treatment is the professional field of the company, so as to ensure the stability of quality.

Material guarantee: In order to ensure product quality, the company has medium carbon steel, high carbon steel, alloy steel, tool steel, high speed steel, tungsten steel for customer demand order, and the spectrometer is used to detect whether the material is correct.

Hardness guarantee: Only by mastering the heat treatment by oneself can the tool reach its best effect and highlight the soul of the tool, and heat treatment is the professional field of the company, so as to ensure the stability of quality.

Shredder Blade

The shredder blade is forged, annealed, heat-treated, tempered for heat preservation, wire cutting, and fine grinding

Reducer

Steel plate welding, high precision, good contact, low noise, and long service life

Electric Box

The shredder adopts an excellent electrical box with high efficiency and a long service life

Motor

The shredder 3KW motor adopts all copper core motor to reduce energy consumption

A:Are you manufacture or trading company?

We are professional manufacture with more than 10 years experience in this field.

A:Can you customize carbdie tools?

We can manufacture tools from standard end mills to special tools according to your needs.

A:Can I get samples before my order?

We provide free samples to every customer, but, we need to freight collect .Or freight prepaid.

A:what kind of payment torment we can use?

Payment terms we can accept as follows: T/T, Western Union. For small amount, usually we accept 100% T/T, and buyer bear bank charges .If pay for big order, 30%-50% in advance before produce.

A:What is the delivery time if I place my order?

It depends on the complexity of the Blade, or the quantity you ordered .If It is our standard project, We will only need 5-7

working days to send out your goods.

If you have an urgent deadline, we'll see what we can do.

working days to send out your goods.

If you have an urgent deadline, we'll see what we can do.

A:Can I Put My Logo On The Product?

Yes, you can .Your Logo Can Be Put on the Product by Mold Punching, Laser Making, and Silk-Screen etc.

Hot Searches