- Product Details

- {{item.text}}

Quick Details

-

Oiled or Non-oiled:

-

Customized

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HYT

-

Outer Diameter:

-

20 - 200 mm

-

Thickness:

-

1 mm ~ 60 mm

-

Technique:

-

ERW,SAW,EFW

-

Grade:

-

A53 A333 A519 A500 A335 A513

-

Product name:

-

Galvanized Steel Tube

-

Surface:

-

Black Painted, galvanized coating

-

Shape:

-

Round Pipe Tube

-

Type:

-

Seamless Welded Steel Pipe

-

Material:

-

Q235/Q235B/Q345/Q345B/A106/A53

-

Keyword:

-

Galvanzied Steel Pipe

-

Usage:

-

Oil Gas Sewage Transport/building

-

MOQ:

-

1 Ton

-

Packing:

-

Standard Seaworthy Packing

Quick Details

-

Section Shape:

-

Round

-

Surface Treatment:

-

galvanized

-

Tolerance:

-

±1%

-

Oiled or Non-oiled:

-

Customized

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HYT

-

Outer Diameter:

-

20 - 200 mm

-

Thickness:

-

1 mm ~ 60 mm

-

Technique:

-

ERW,SAW,EFW

-

Grade:

-

A53 A333 A519 A500 A335 A513

-

Product name:

-

Galvanized Steel Tube

-

Surface:

-

Black Painted, galvanized coating

-

Shape:

-

Round Pipe Tube

-

Type:

-

Seamless Welded Steel Pipe

-

Material:

-

Q235/Q235B/Q345/Q345B/A106/A53

-

Keyword:

-

Galvanzied Steel Pipe

-

Usage:

-

Oil Gas Sewage Transport/building

-

MOQ:

-

1 Ton

-

Packing:

-

Standard Seaworthy Packing

Product Specification

ASTM A106 Carbon Steel Pipe Specification and Dimension

Jiangsu HYT supplys ASTM A106 seamless carbon steel pipes in:

Standard: ASTM A106

Grade: A, B, C

Range of OD outer diameter: NPS 1/8 inch to NPS 20 inch, 10.13mm to 1219mm

Range of WT wall thickness: SCH 10, SCH 20, SCH STD, SCH 40, SCH 80, to SCH160, SCHXX; 1.24mm up to 1 inch, 25.4mm

Range of length: 20ft to 40ft, 5.8m to 13m, single random lengths of 16 to 22ft, 4.8 to 6.7m, double random length with average 35ft 10.7m

Ends procession: Plain end, beveled, threaded

Coating: Black paint, varnished, epoxy coating, polyethylene coating, FBE and 3PE, CRA Clad and Lined.

Scope of ASTM A106

ASTM A106 and ASME SA106 covers seamless carbon steel nominal wall pipe for high-temperature service. Suitable for bending, flanging and similar forming operations.

NPS 1-1/2″ and under may be either hot finished or cold drawn. NPS 2″ and larger shall be hot finished unless otherwise specified.

Application of ASTM A106 Seamless and Welded Carbon Steel Pipe

Petrochemical and Chemical Industry : These pipes are used for the conveyance of fluids in high temperature and high-pressure applications.

Power Plants : ASTM A106 pipes are used in power plants for transporting steam and other high-temperature fluids from the boilers to the turbines.

Oil and Gas Industry : For transporting oil, gas, and other hydrocarbons under high temperatures and pressures.

Refineries : Used for transferring oils at high temperatures.

Ship Building : For pipes that are used in the shipbuilding process, especially those that handle high-temperature fluids.

Boilers : Used as boiler tubes to transport hot gases and fluids.

High-Temperature Services : Any application requiring the transport of fluids under high temperature, such as in heat exchangers.

Structural and Piling : Sometimes used for structural applications and piling, although there are other specifications more dedicated to these purposes.

General Engineering : For various engineering applications due to its durability under high-temperature conditions.

Water and Sewage : Though not its primary application, it can be used for water and sewage conveyance in situations requiring high-temperature resistance.

Jiangsu HYT supplys ASTM A106 seamless carbon steel pipes in:

Standard: ASTM A106

Grade: A, B, C

Range of OD outer diameter: NPS 1/8 inch to NPS 20 inch, 10.13mm to 1219mm

Range of WT wall thickness: SCH 10, SCH 20, SCH STD, SCH 40, SCH 80, to SCH160, SCHXX; 1.24mm up to 1 inch, 25.4mm

Range of length: 20ft to 40ft, 5.8m to 13m, single random lengths of 16 to 22ft, 4.8 to 6.7m, double random length with average 35ft 10.7m

Ends procession: Plain end, beveled, threaded

Coating: Black paint, varnished, epoxy coating, polyethylene coating, FBE and 3PE, CRA Clad and Lined.

Scope of ASTM A106

ASTM A106 and ASME SA106 covers seamless carbon steel nominal wall pipe for high-temperature service. Suitable for bending, flanging and similar forming operations.

NPS 1-1/2″ and under may be either hot finished or cold drawn. NPS 2″ and larger shall be hot finished unless otherwise specified.

Application of ASTM A106 Seamless and Welded Carbon Steel Pipe

Petrochemical and Chemical Industry : These pipes are used for the conveyance of fluids in high temperature and high-pressure applications.

Power Plants : ASTM A106 pipes are used in power plants for transporting steam and other high-temperature fluids from the boilers to the turbines.

Oil and Gas Industry : For transporting oil, gas, and other hydrocarbons under high temperatures and pressures.

Refineries : Used for transferring oils at high temperatures.

Ship Building : For pipes that are used in the shipbuilding process, especially those that handle high-temperature fluids.

Boilers : Used as boiler tubes to transport hot gases and fluids.

High-Temperature Services : Any application requiring the transport of fluids under high temperature, such as in heat exchangers.

Structural and Piling : Sometimes used for structural applications and piling, although there are other specifications more dedicated to these purposes.

General Engineering : For various engineering applications due to its durability under high-temperature conditions.

Water and Sewage : Though not its primary application, it can be used for water and sewage conveyance in situations requiring high-temperature resistance.

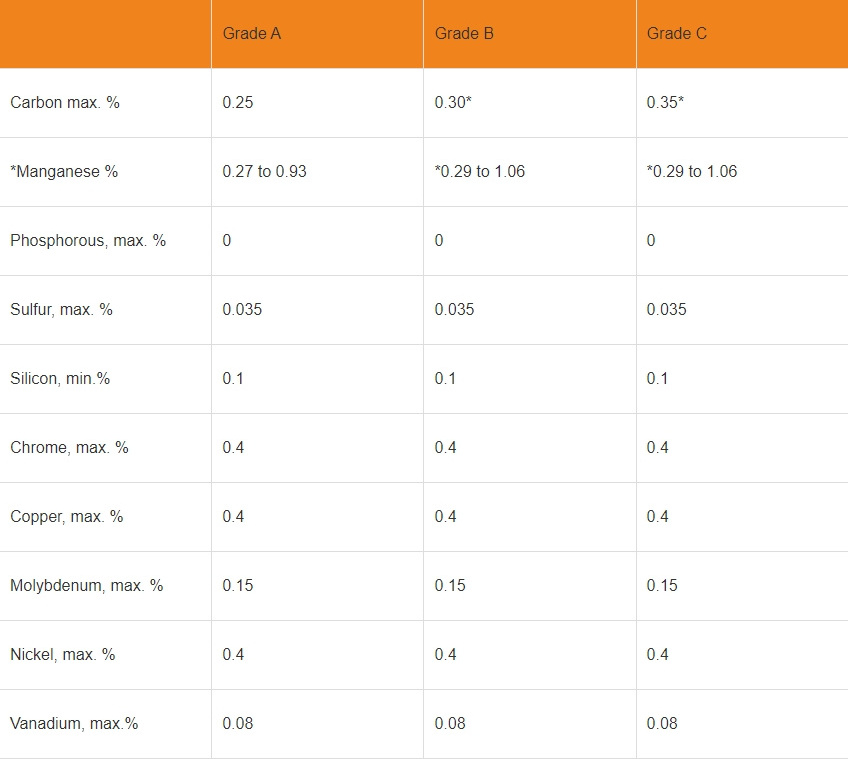

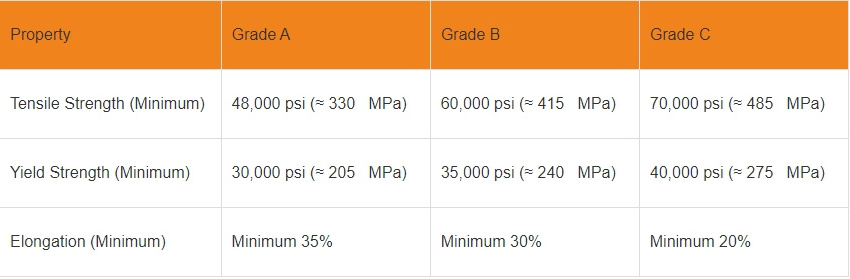

Chemical Composition of ASTM A106 Pipe

Mechanical Property of ASTM A106 Pipe

Benefits of ASTM A106 Pipe

High-Temperature Performance : Designed specifically for high-temperature service, A106 steel pipes maintain excellent mechanical properties even in high-temperature environments.

Good Weldability : ASTM A106 piping possesses outstanding weldability, making it highly desirable in various engineering applications.

Mechanical Properties : It offers high yield and tensile strength, making it suitable for applications requiring high strength.

Seamless Design : Due to its seamless construction, these pipes are especially beneficial for high-pressure applications of liquids and gases as they provide more uniform thickness and fewer potential leakage points.

Standardization : ASTM A106 offers clear guidelines and standards ensuring that pipes produced by all manufacturers are consistent in quality, dimensions, and performance.

Corrosion Resistance : Although the basic A106 is not designed for corrosion resistance, it can undergo additional treatments or coatings, like galvanization, to enhance its resistance to corrosion.

Wide Range of Choices : ASTM A106 offers several different grades, such as Grade A, B, and C, catering to different mechanical properties and application needs.

Cost-Effectiveness : Considering its performance and reliability, A106 steel pipes offer an economical and efficient choice.

Diversity of Applications : Due to its characteristics, ASTM A106 piping is widely used in refineries, chemical plants, power plants, and other applications that require resistance to high temperatures and pressures.

Environmental Considerations : Carbon steel is recyclable, meaning that A106 steel pipes can be recycled and reused once their life cycle ends.

Our Supply Range for ASTM A106 Pipe

Jiangsu HYT supplys ASTM A106 seamless carbon steel pipes in:

Standard: ASTM A106

Grade: A, B, C

Range of OD outer diameter: NPS 1/8 inch to NPS 20 inch, 10.13mm to 1219mm

Range of WT wall thickness: SCH 10, SCH 20, SCH STD, SCH 40, SCH 80, to SCH160, SCHXX; 1.24mm up to 1 inch, 25.4mm

Range of length: 20ft to 40ft, 5.8m to 13m, single random lengths of 16 to 22ft, 4.8 to 6.7m, double random length with average 35ft 10.7m

Ends procession: Plain end, beveled, threaded

Coating: Black paint, varnished, epoxy coating, polyethylene coating, FBE and 3PE, CRA Clad and Lined.

High-Temperature Performance : Designed specifically for high-temperature service, A106 steel pipes maintain excellent mechanical properties even in high-temperature environments.

Good Weldability : ASTM A106 piping possesses outstanding weldability, making it highly desirable in various engineering applications.

Mechanical Properties : It offers high yield and tensile strength, making it suitable for applications requiring high strength.

Seamless Design : Due to its seamless construction, these pipes are especially beneficial for high-pressure applications of liquids and gases as they provide more uniform thickness and fewer potential leakage points.

Standardization : ASTM A106 offers clear guidelines and standards ensuring that pipes produced by all manufacturers are consistent in quality, dimensions, and performance.

Corrosion Resistance : Although the basic A106 is not designed for corrosion resistance, it can undergo additional treatments or coatings, like galvanization, to enhance its resistance to corrosion.

Wide Range of Choices : ASTM A106 offers several different grades, such as Grade A, B, and C, catering to different mechanical properties and application needs.

Cost-Effectiveness : Considering its performance and reliability, A106 steel pipes offer an economical and efficient choice.

Diversity of Applications : Due to its characteristics, ASTM A106 piping is widely used in refineries, chemical plants, power plants, and other applications that require resistance to high temperatures and pressures.

Environmental Considerations : Carbon steel is recyclable, meaning that A106 steel pipes can be recycled and reused once their life cycle ends.

Our Supply Range for ASTM A106 Pipe

Jiangsu HYT supplys ASTM A106 seamless carbon steel pipes in:

Standard: ASTM A106

Grade: A, B, C

Range of OD outer diameter: NPS 1/8 inch to NPS 20 inch, 10.13mm to 1219mm

Range of WT wall thickness: SCH 10, SCH 20, SCH STD, SCH 40, SCH 80, to SCH160, SCHXX; 1.24mm up to 1 inch, 25.4mm

Range of length: 20ft to 40ft, 5.8m to 13m, single random lengths of 16 to 22ft, 4.8 to 6.7m, double random length with average 35ft 10.7m

Ends procession: Plain end, beveled, threaded

Coating: Black paint, varnished, epoxy coating, polyethylene coating, FBE and 3PE, CRA Clad and Lined.

Other Product Details

|

Brand

|

HYT

|

|

|

|

|||

|

Origin

|

China

|

|

|

|

|||

|

Application Industry

|

Oil and Gas, Construction, Water Supply and Treatment, Automotive, Power Generation, etc.

|

|

|

|

|||

|

Surface Treatment

|

Acid pickling, Wire drawing, Polishing, Sandblasting, Shot blasting, Electrochemical polishing, Titanium plating, PVD (Physical Vapor Deposition), Chemical coloring, Heat treatment, Annealing.

|

|

|

|

|||

|

Surface Finish

|

NO.1, 2D, 2B, BA (Bright Annealed), NO.3, NO.4, HL (Hair Line), NO.7, NO.8, SATIN.

|

|

|

|

|||

|

Color

|

Silver (Natural Steel), Black (Coated or Oxidized), Galvanized (Zinc), Green (Coated), Blue (Coated), Red (Coated), Yellow (Coated), White (Coated).

|

|

|

|

|||

|

Pipe Ends

|

Plain End (PE), Beveled End (BE), Threaded End (TE), Grooved, Bell End, Tapered, Expanded.

|

|

|

|

|||

|

Tolerance

|

As standards’ Requirements

|

|

|

|

|||

|

Test

|

Support Third-party Test.

|

|

|

|

|||

|

Certification

|

GB/T19001-2016/ISO9001:2015

GB/T24001-2016/ISO14001:2015 GB/T 45001-2020/ISO 45001:2018 |

|

|

|

|||

|

Processing Service

|

Cutting, Bending, Threading, Welding, Grooving, Coating, Drilling, Galvanizing, Heat Treatment, Punching.

|

|

|

|

|||

|

Sample

|

Free Sample Available

|

|

|

|

|||

|

Stock Status

|

Continuous Supply Of Spot Products

|

|

|

|

|||

|

MOQ

|

1 Ton

|

|

|

|

|||

|

Packaging

|

Bundled, Wooden Cases, Plastic Wrapping, Plastic Caps, Palletized, Shrink Wrapped, Plastic Bagged, Steel Crates, Loose, Boxed.

|

|

|

|

|||

|

Port

|

Shanghai

|

|

|

|

|||

|

Delivery Term

|

EXW, FOB, FCA, etc.

|

|

|

|

|||

|

Delivery Time

|

3-5 days for the regular models, and 7 to 10 working days for the special sizes and processing

|

|

|

|

|||

|

Payment Term

|

T/T, L/C, D/P, etc.

|

|

|

|

|||

|

Customization

|

Customization Available

|

|

|

|

|||

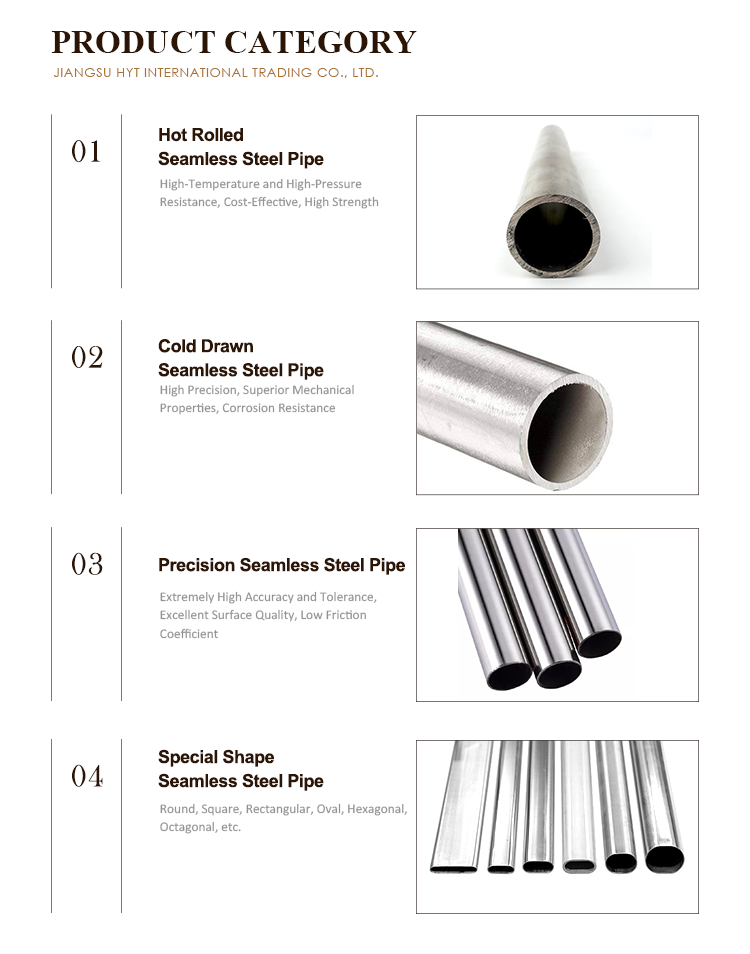

Product Category

Product Application

Wide Application Range Help You Overcome Tough Projects

Our metal products are widely used in industrial electric furnaces, civil nuclear power, power station boilers, petrochemical

industry, aerospace, ships, automobiles, machinery, communication electronics, instruments for the application of high resistance, high temperature, corrosion resistance, heat resistance, wear resistance, fatigue, creep and other use environment. We provide customers with scientific solutions and excellent product service from the material perspective.

Hot Searches