- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

600 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Haisi

-

Voltage:

-

380v or as require

-

Dimension(L*W*H):

-

Machine Model

-

Power (kW):

-

75

-

Weight:

-

4000 KG

-

Model Number:

-

TSE-52B

-

plastic processed:

-

abs/eva colored pellet

-

Type:

-

Granulating Production line

-

Screw Shaft:

-

38CrMoALA /W6Mo5Cr4V2

-

Power:

-

55kw

-

Warrenty:

-

1 year

-

Automatic Grade:

-

Semi-automatic

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

44

-

Screw diameter (mm):

-

52 mm

-

Screw Speed (rpm):

-

600 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Haisi

-

Voltage:

-

380v or as require

-

Dimension(L*W*H):

-

Machine Model

-

Power (kW):

-

75

-

Weight:

-

4000 KG

-

Model Number:

-

TSE-52B

-

plastic processed:

-

abs/eva colored pellet

-

Type:

-

Granulating Production line

-

Screw Shaft:

-

38CrMoALA /W6Mo5Cr4V2

-

Power:

-

55kw

-

Warrenty:

-

1 year

-

Automatic Grade:

-

Semi-automatic

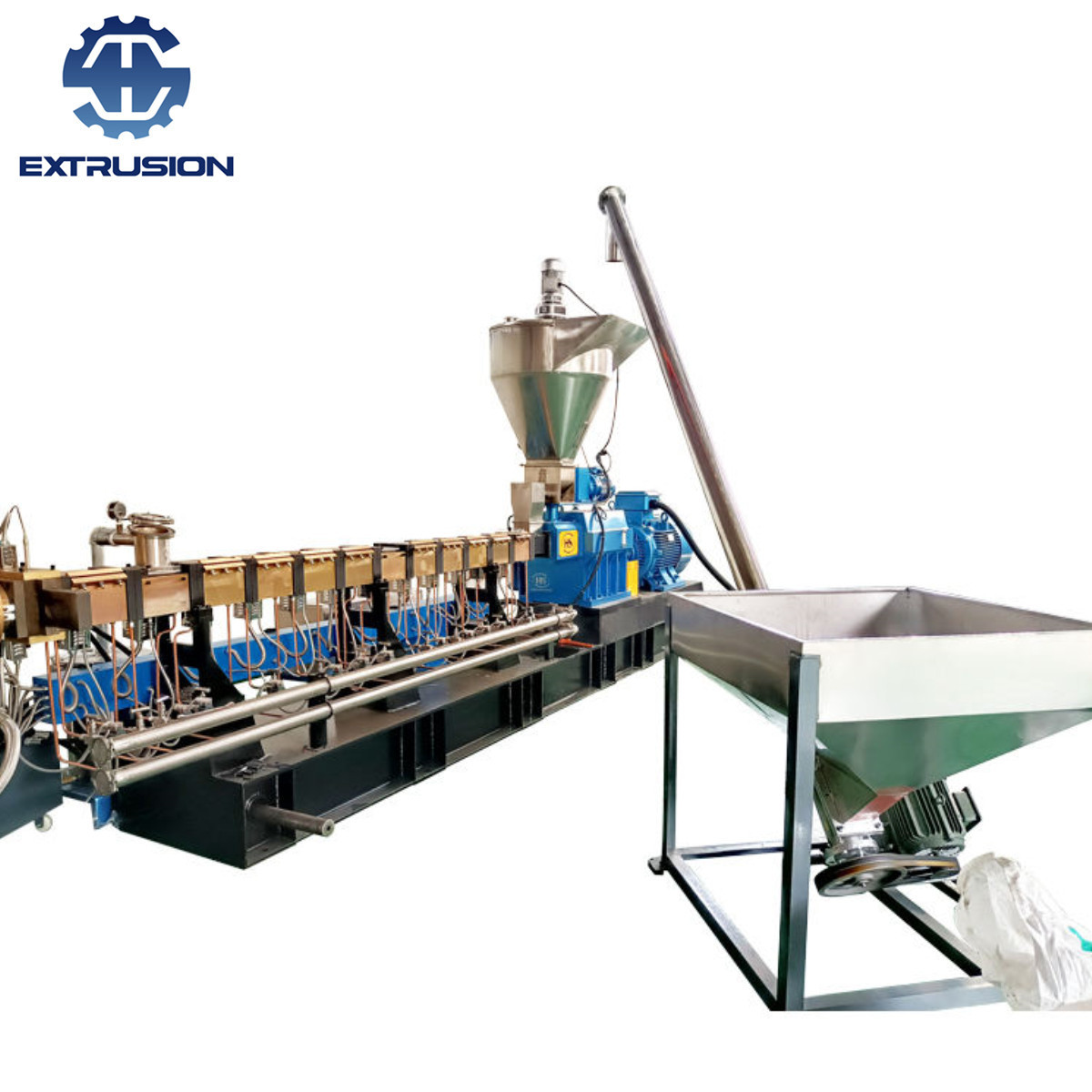

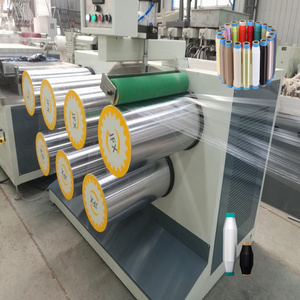

PET plastic monofilament extruder machine for broom

Application

a. For high filling masterbatch : PE/PP/EVA ,+ Caco3, Tio2, Talc,Carbon Black , etc;

b. For fiber reinforcement: PP/PA/PBT/ABS/AS/PC/POM/PPS/PET +glass fiber, carbon black ;

c. For color masterbatch: PE/ABS/PS/EVA/PET/PP +Pigment, addictives;

PP + 30% Pigments+ Caco3 + Addictives;

Including mixer for mixing PE+ pigments + Addictives; Screw loader for loading materials; Extruder for extrusion ; Water strand pelletizing line for cooling and cutting;

PE + 85% Caco3;

Including High speed mixer for mixing PE+85% Caco3+ addictives; Screw loader for loading materials ; Extruder for extrusion; Air cooling pelletizing line for cooling and cutting ;

PP +70% Caco3 ;

High speed mixer for mixing PE+ Caco3+ Addictives; Screw loader for loading materials , Extruder for extrusion; Water ring pelletizing line for cooling and pelletizing ;

PE/PP/EVA + Caco3/Talc/Tio2/ pigments ;

Specification

a. Flexible modular screw barrel sections : high quality nitrided steel, corrosion proof or antifriction with corresponding process ; Cooled by water , by means of an internal bore system , with bores arranged close to the inside barrel wall:

b. Screws are designed as modular systems. The screw elements are slid onto the shaft in the desired configuration. The unique splined screw shaft design-maxx shaft -realizes a higher torque transmission than in standard extruders. Generally , there are conveying, kneading , mixing elements. Hundreds of different screw elements can be combined.W6Mo5Cr4V2 or 38 CrMoALA.

c. Metering feeders are equipped with single screw, twin screw , hollow screw, forced-feeding, side-feeding, system etc. to meet different requirements of feeding ,such as powder, pellet, lump and liquid mateials

D.High toruque Gearbox: new stype project of parallel three axises driving makes the convey axis, selected materials of drive components is dainty. Including super intention alloy cementiteing steel, cementiting and grinding. technics, strengthening of tooth face.

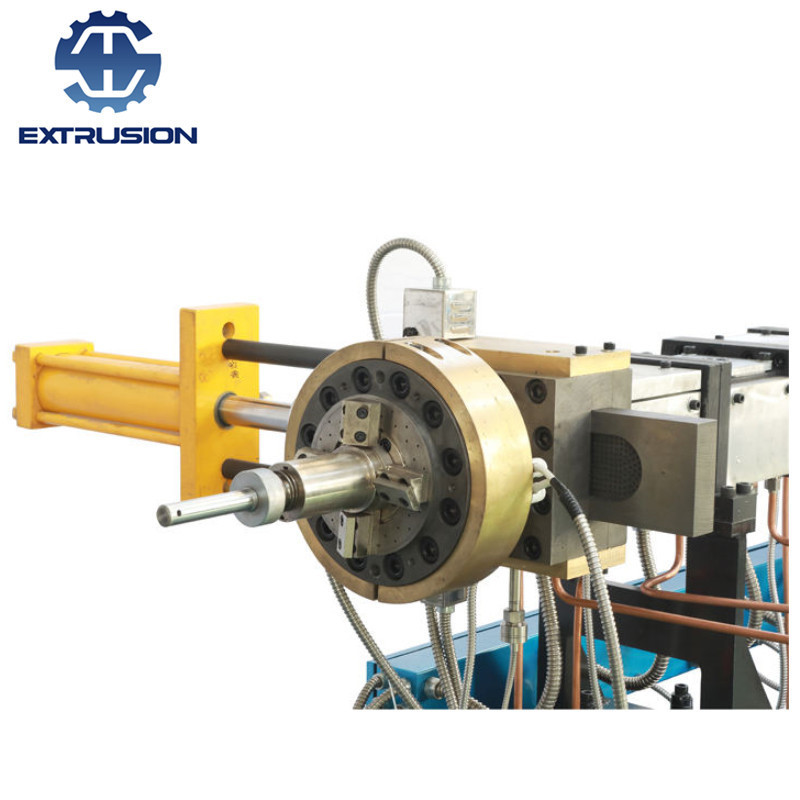

E. Various pelletizing line for different kinds of masterbatch and compounds;

Water strand pelletizing line for various filling masterbatch ,fiber reinforcement masterbatch ,etc

Air cooling pelletizing line for PE+ Caco3/ Pigment ,etc

Water ring pelletizing line for PP+70-85% Caco3/Talc/Tio2,etc.

Under water pelletizing line for TPU, etc

F. Electrical control system

-Adopting imported PLC (OMRON or SIMES) to achieve optimized process control. Stronger function, steady performance and much higher accuracy.

-It can be also accomplished full-set link-lock protection,trouble safeguard, fault alarm cluing and so on.

-Operation interface on touching screen is visual an marked, which is brief and easy to use.

Our manufacture

Other representative materials

- filling and modification:PE,PP,EVA+caco3;ABS,PC,PS+aluminum hydroxide,magnesium hydroxide,antimony oxide

- general and fibre color masterbatch:PE,PP,ABS,AS,PA,EVA,PET+pigment and auxiliary;PE,EVA,ABS+carbon black machine pellets.

- blending modification(rubber&plastic blending ,plastic alloy) PE,PP,PS+SBS;PA+EPDM;PP+NBR;PP+PE,etc.

- functional masterbatch:PE,PP,PS+starch: de-composing machine pellets.

- glass fibre or carbon reinforcement:PP,PBT,ABS,AS,PA,PC,POM,PPS,PET+long fires,small fibres,carbon fibres,crystals and so on,etc.

- various cable material :HDPE,LDPE,LLDPE,MDPE,EVA,PVC,PP etc.

- handling after dewatering:polystyrene oxide,high-absorbing resin,chlorine sulphur polyethylene,etc

- powder coating and special material : polyester,ring oxide,lactide,polyurethane,acrylate,etc.

Other extruder parameter

| Mode |

Screw Diameter D(mm) |

L/D |

Screw Rotation N( r/min) |

Main Power P(kw) |

Main Torque T(N.m) |

T/N3 |

Output Q(kg/h) |

| TSE-20 | 22 | 32-44 | 600 | 5.5 | 43 | 7.5 | 0.5-10 |

| TSE-30A | 31 | 32-48 | 500 | 11 | 105 | 5.9 | 5-30 |

| TSE-30B | 31 | 32-48 | 600 | 15 | 119 | 6.7 | 5-40 |

| TSE-35A/B | 35.6 | 32-52 | 600 | 15-22 | 119 | 4.4 | 20-60 |

| TSE-40A | 41 | 32-64 | 400 | 22 | 263 | 6.4 | 65-110 |

| TSE-40B | 41 | 32-52 | 600 | 30 | 239 | 5.8 | 90-150 |

| TSE-50A/B | 50.5 | 32-52 | 500 | 45-55 | 430 | 5.4 | 135-270 |

| TSE-65A | 62.4 | 32-52 | 400 | 75 | 895 | 6.3 | 180-250 |

| 500 | 75 | 716 | 5.1 | 180-270 | |||

| TSE-65B | 62.4 | 32-64 | 600 | 90 | 716 | 5.1 | 200-300 |

| TSE-65C | 62.4 | 32-64 | 600 | 110 | 875 | 6.2 | 220-350 |

| TSE-75A | 71 | 32-56 | 400 | 90 | 1074 | 4.9 | 250-350 |

| 500 | 110 | 1050 | 4.8 | 300-420 | |||

| TSE-75B | 71 | 32-64 | 600 | 132 | 1050 | 4.8 | 350-550 |

| TSE-75C | 62.4 | 32-64 | 600 | 160 | 1273 | 5.8 | 400-600 |

| TSE-75D | 71 | 32-64 | 600 | 200-250 | 1990 | 9.2 | 500-1000 |

Any questions, please contact me