- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

300*150*100 mm, Other, 230*220*100mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

wante

-

Voltage:

-

220v/380v

-

Dimension(L*W*H):

-

3100*1500*1400mm

-

Weight (KG):

-

1200 kg

-

Product Name:

-

brick making machine

-

Raw material:

-

Clay Soil Earth

-

Brick type:

-

Interlock Brick Clay Brick Hole Brick

-

Brand:

-

wante

-

Power:

-

Diesel 18 HP

-

Main market:

-

African Countries

-

Color:

-

Customer's Demand

-

Forming cycle:

-

10-15s

-

Total weight:

-

1200kgs

-

Application:

-

Construction Industry

Quick Details

-

Type:

-

Interlock Block Making Machine

-

Brick Raw Material:

-

Clay

-

Production Capacity (Pieces/8 hours):

-

2000 pcs/8hours

-

Brick size:

-

300*150*100 mm, Other, 230*220*100mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

wante

-

Voltage:

-

220v/380v

-

Dimension(L*W*H):

-

3100*1500*1400mm

-

Weight (KG):

-

1200 kg

-

Product Name:

-

brick making machine

-

Raw material:

-

Clay Soil Earth

-

Brick type:

-

Interlock Brick Clay Brick Hole Brick

-

Brand:

-

wante

-

Power:

-

Diesel 18 HP

-

Main market:

-

African Countries

-

Color:

-

Customer's Demand

-

Forming cycle:

-

10-15s

-

Total weight:

-

1200kgs

-

Application:

-

Construction Industry

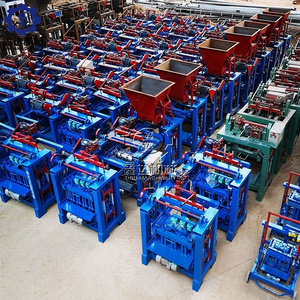

WT1-20M interlocking bricks manufactures block manual brick diesel machine block machine price

The WT1-20M i nterlocking block forming machine includes a diesel engine. Hydraulic power pack, including cylinder and a compression chamber. All of these are installed on the trailer, including spring axles, tail lights, trailer hooks, and road tires. Unskilled labor can operate easily. A machine can produce different types of interlocking blocks by changing molds. This machine is a new type of brick machine developed based on the huge market potential in Africa. Compared with other machines, its biggest advantages are simple structure, convenient operation, and low cost, making it a perfect choice for small investors in under developed regions. Using a hydraulic system, the density of bricks is much higher than that of bricks formed by mechanical vibrators. The mold of this machine is manufactured with high-precision tools, ensuring the accurate size of the bricks, and the error can be controlled within 0.1mm.Therefore, the bricks it produces have clear edges, smooth lines, and beautiful shapes. The buildings built with these bricks will have a more pronounced three-dimensional nature, which is incomparable to other traditional products.

it use diesel engine, no need electric, so it is very good for the place where there is no power or electricity

Technical Parameter

| Overall size of main machine | 3100*1500*1400mm |

| Power | Diesel 18 HP |

| Weight | 1200kgs |

| Shaping type | hydraulic press |

| Forming period |

10-15S |

WT1-20M clay interlocking brick making machine can produce various different bricks by changing mould. The following bricks are some common brick types. We can also customize the brick mould according to your specific requirements.

| Size(L*W*H) |

Pcs/Mould |

Pcs/Hr | Pcs/8Hrs |

| 300*150*100mm | 1 | 250 | 2000 |

|

230*220*100mm |

1 | 250 | 2000 |

Packing is nude package, plastic and wooden case according to customer need:

1. The whole brick machine production line equipment is mainly the full container sea shipping,

2. Before shipment, the top paint of the brick machine equipment will be tested and cleaned up, and then another paint protection will be done.

3. Before shipment, it can be wrapped with plastic film according to customer needs, and the whole brick machine is wrapped to prevent water or moisture.

4. The brick machine is then loaded into the container by a crane or forklift.

5. When loading, the reinforcing ring and special equipment in the container are used to tighten the machine to prevent damage to the brick machine caused by transportation bumps.

Linyi Wante Machinery Co., Ltd. has long engaged in the research, production and sales of block making machines. Our main products: Concrete block making machines,Clay soil brick machine,stone coated metal roof tile. widely used in building materials, roads and bridges, energy and others. Our products have been exported to more than 100 countries and regions, such as Africa, Southeast Asia, the Middle East and South America, with frequent international business dealings. We have established a good market reputation. Our company has a perfect quality management system, and has passed the ISO9001:2000 international quality management system certification.

We continue to pay attention to the use of customers' machines, solve production problems in time and provide vulnerable parts.These are some feeback from our customer.

Pre-sale service

1.Provide quotation and pictures,working videos of machine.

2.Provide drawings for block designs

3. Customized your machine

While-sale service

1.Report the production process for customers

2.Testing machine machine before delivery and send videos

3.Arrange shipping and delivery

After-sale service:

1.Design land layout drawings,provide manual book,installation videos

2.Engineer available overseas installation

3.24hours online service

4.One year quality warranty.

5.Send spare parts

FAQ:

1.How to proceed an order for brick making machine?

Firstly,please let me know your raw material, ideal block design and size,capacity range.Secondly,we will send you machine video,price list,specifications for reference.Thirdly,order details confirmation and production.

2.Can I show my company logo on the bricks or on the machine?

Yes,we can produce the mold with your company logos,and paint your company logo on machine.

3.Do you offer warranty for the machine?

Yes,we provide free spare parts with the machine,and the quality warranty is one year.

4.What's the payment terms?

30% T/T in advance,70% balance before delivery.

5.What's the delivery time?

Usually 25-30 days we can finish production.