- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Construction

-

Design Style:

-

Industrial

-

Type:

-

plastic formwork

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

Pengxiang Trading

-

Model Number:

-

Alloy reinforced

-

size:

-

Custom sizes are supported

-

Material:

-

Plastic alloy modified material ;Polypropylene resin

-

Color:

-

Gray White

-

Tensile Strength:

-

≥18.0Mpa

-

Charpy impact strength:

-

≥21.0KJ/m²

-

Bending strength:

-

≥31.0Mpa

-

Flexural modulus of elasticity:

-

≥1100 Mpa

-

Shrinkage rate (longitudinal):

-

≤0.8%

-

Retraction rate (transverse direction):

-

≤0.6%

-

Screw holding force (board surface):

-

≥1200N

Quick Details

-

Warranty:

-

2 years

-

After-sale Service:

-

Online technical support

-

Project Solution Capability:

-

total solution for projects

-

Application:

-

Construction

-

Design Style:

-

Industrial

-

Type:

-

plastic formwork

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

Pengxiang Trading

-

Model Number:

-

Alloy reinforced

-

size:

-

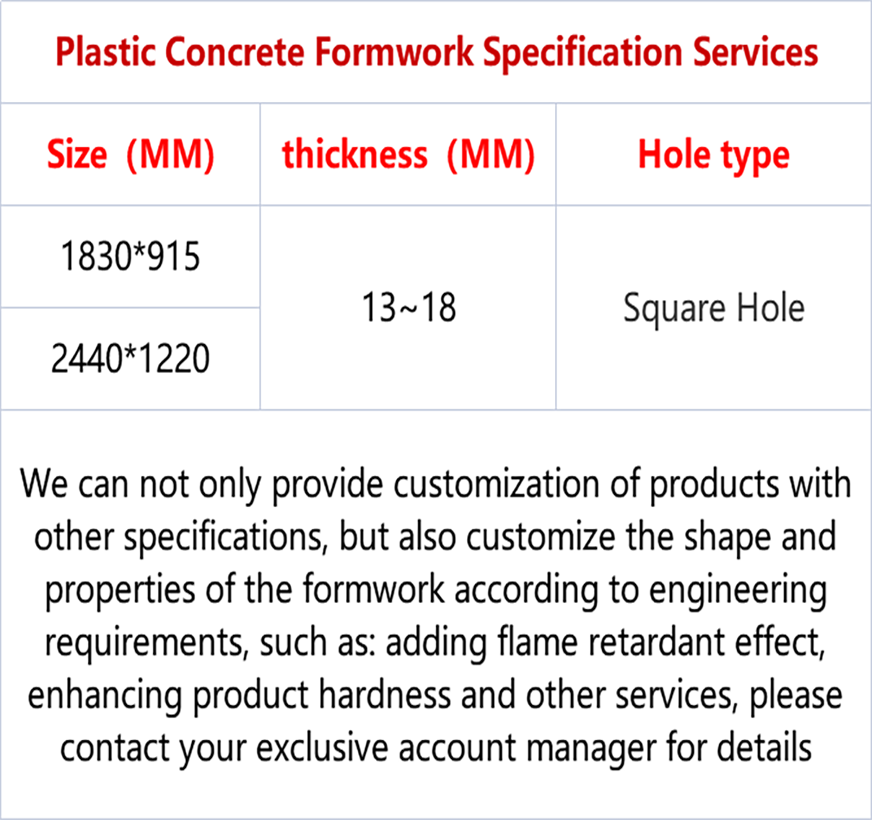

Custom sizes are supported

-

Material:

-

Plastic alloy modified material ;Polypropylene resin

-

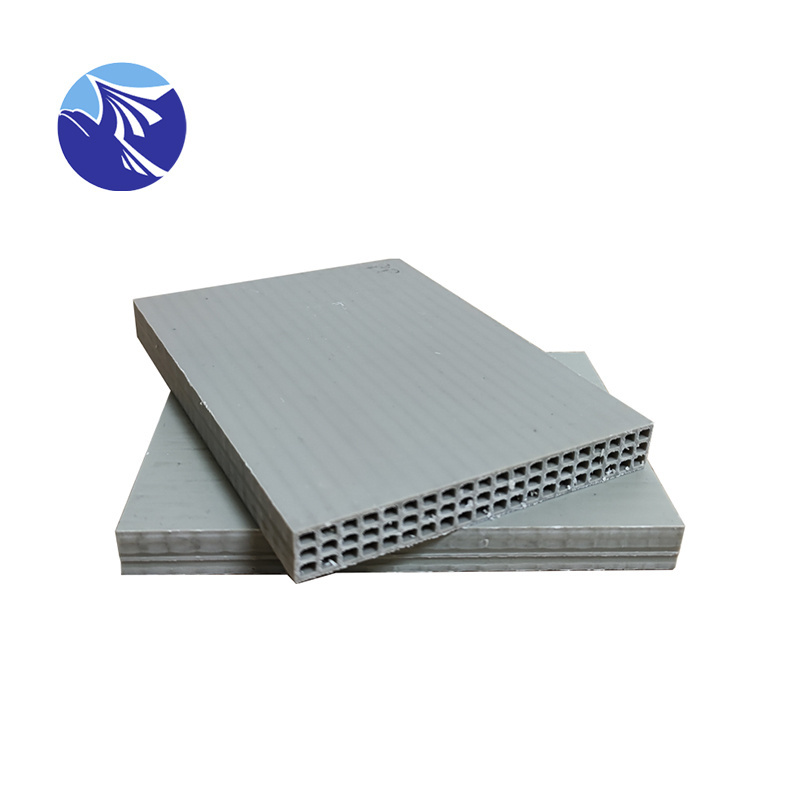

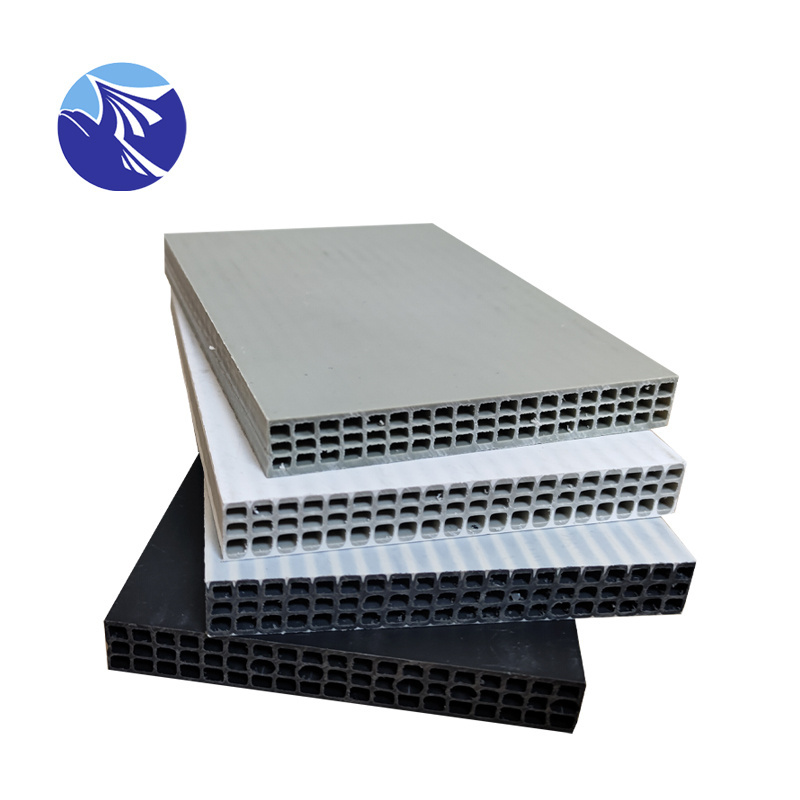

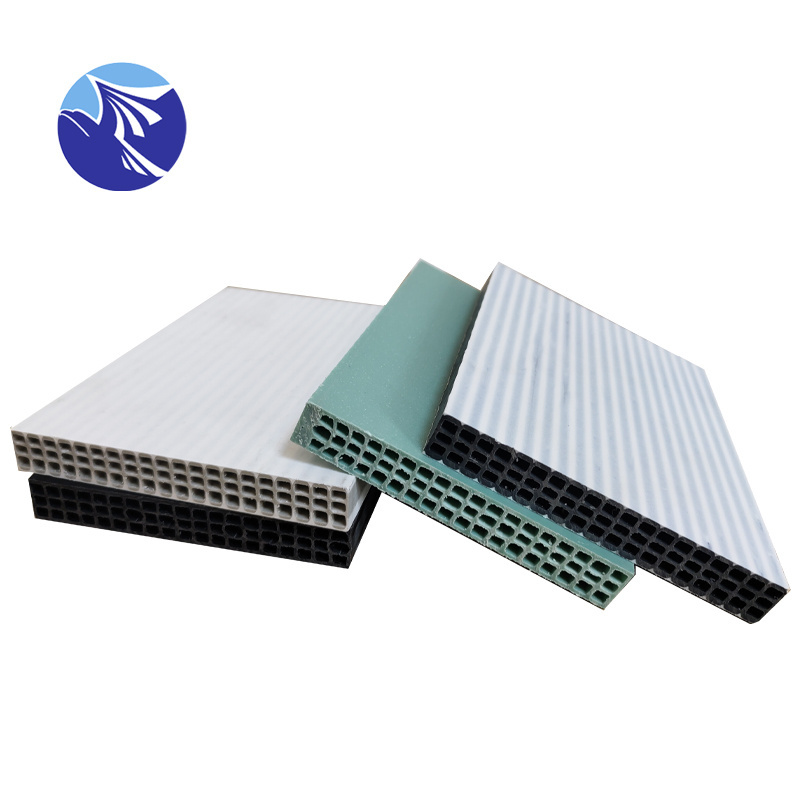

Color:

-

Gray White

-

Tensile Strength:

-

≥18.0Mpa

-

Charpy impact strength:

-

≥21.0KJ/m²

-

Bending strength:

-

≥31.0Mpa

-

Flexural modulus of elasticity:

-

≥1100 Mpa

-

Shrinkage rate (longitudinal):

-

≤0.8%

-

Retraction rate (transverse direction):

-

≤0.6%

-

Screw holding force (board surface):

-

≥1200N

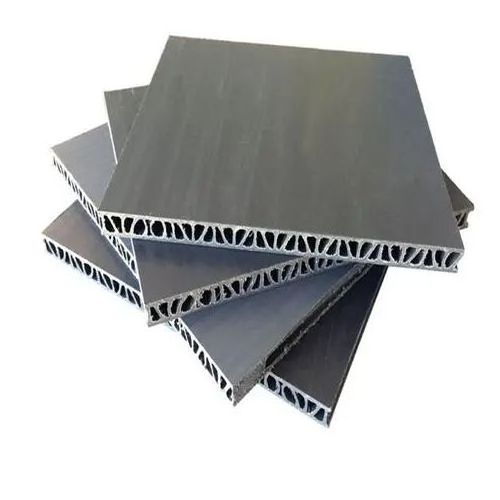

Products Description

What is plastic formwork?

The building formwork is a temporary support structure, which is manufactured according to the design requirements, so that theconcrete structure and components are formed according to the specified position and geometric size, maintain their correct position, and bear the self-weight of the building formwork and the external load acting on it. Building formwork is mainly divided into wooden building formwork, steel-wood building formwork, building plywood, steel-bamboo building formwork, plastic building formwork, etc. Plastic formwork is an energy-saving and green environmental protection product. It is another new generation product after wood formwork, composite steel formwork, bamboo-wood glued formwork, and all-steel large formwork. It can completely replace the traditional steel formwork, pine formwork, energy saving and environmental protection, and low amortization cost.

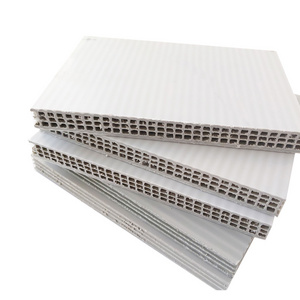

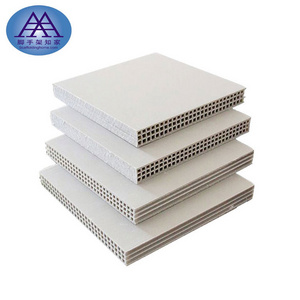

All products in this store are the latest generation of hollow plastic formwork

The first generation of hollow

plastic formwork

The second generation hollow

plastic formwork

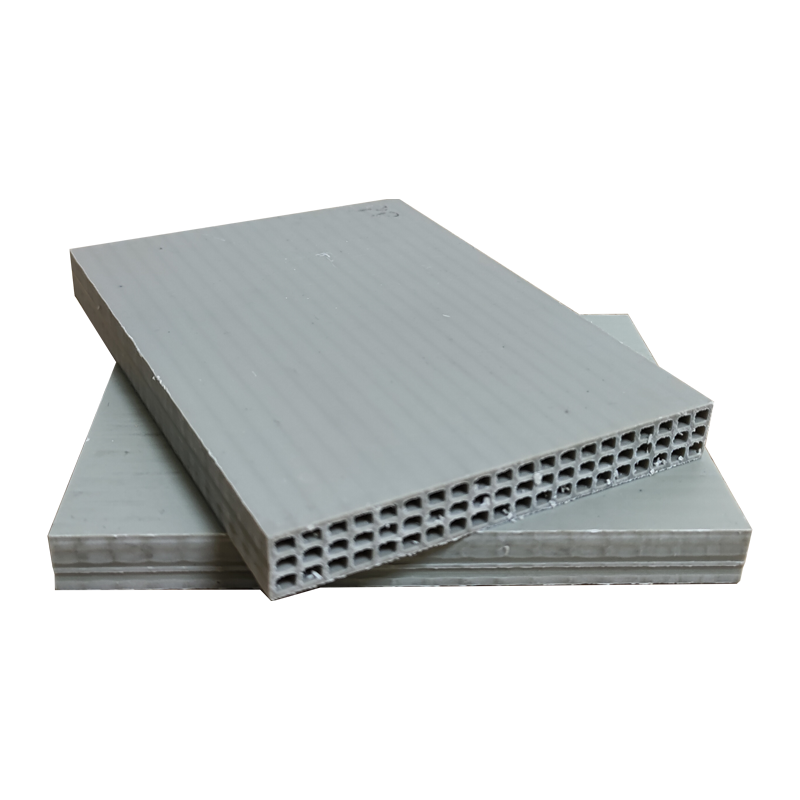

The third generation hollow

plastic formwork

How to distinguish plastic plastic formwork ?

It can be distinguished from the shape of the hole alone. The first generation is a triangle, the second generation is a circle, and the latest third generation is a rectangle.

why choose plastic formwork?

1.

plastic formwork

material is PP alloy material

Moisture resistance, acid resistance, alkali resistance, corrosion resistance,

template rigid plastic combination, high strength, light weight, strong impact resistance Large, can be sawed, planed, nailed

template rigid plastic combination, high strength, light weight, strong impact resistance Large, can be sawed, planed, nailed

2.Convenient construction

Light in weight, complete in specifications, easy tosupport and remove formwork, safe and reliable in construction operation and handling, low in labor intensity, and high in construction efficiency.

3. High turnover times

It has high strength, strong toughness, impact resistance, strong elasticity, and is not easy to deform, thus greatly improving the

turnover of the formwork usage count. The theoretical turnover is 70~80 times, which is reflected in the contract not less than 50

times, see the detailed rules of the contract for details.

turnover of the formwork usage count. The theoretical turnover is 70~80 times, which is reflected in the contract not less than 50

times, see the detailed rules of the contract for details.

4. Fast demoulding speed

The surface is smooth and clean, and it has good peelability with concrete and is easy to release the mold, which can greatly speed up the construction progress and help torealize Faced concrete.

5. Easy to clean and maintain

There is no need to apply a release agent during use, and it is easy to clean and maintain, so the cost of template cleaning and maintenance is reduced.

Can be used 50-100 times Green environmental protection, no pollution Recyclable

Light weight 、 high strength

Good hardness 、 impact resistance

Good hardness 、 impact resistance

Long term immersion in water No deformation, delamination and blistering Non swelling, corrosion resistance, high and low temperature resistance

Easy weight, easy operation and quick construction

Waterproof, corrosion resistant, easy to handle, shorten working hours and save manpower

One time forming is smooth, high quality and low cost

Product technical certification

technical standard

Deep contrast analysis

Easy to support and disassemble the formwork

The surface of the formwork is smooth and clean, with automatic demoulding, no need for cleaning and maintenance, and no release agent is required. The surface of the formwork is not sticky after use. The cement formwork does not need to be cleaned; under the same workload, the construction efficiency can be increased by 40% compared with the steel formwork; compared with the bamboo and wood formwork Compared with that, the construction efficiency can be increased by 40%.

Template assembly saves time

It can be customized to length without on-site processing; with the same building area, the time-consuming hollow energy-saving building formwork is about 40% less than traditional formwork.

The disassembly and assembly time of the formwork is short

The thermal expansion coefficient of the hollow energy-saving building formwork is far different from that of concrete. After pouring, the formwork will automatically separate from the poured concrete as the temperature changes and the concrete solidifies.

The formwork is convenient and safe to carry

The density of hollow building formwork is 0.4 g/cm3, which is 1/21 of that of steel. It is light in weight and easy for workers to carry. The formwork will not be deformed during use, which can greatly improve construction safety, and its damage rate is less than 1%.

Use effect display

Hot Searches