- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Customize

-

Weight (KG):

-

8500

-

Raw material:

-

Coconut Shell

-

Final product:

-

Coconut Shell Charcoal

-

Final product usage:

-

Make Charcoal Briquettes

-

Color:

-

Customer's Request

-

Carbonization time:

-

30 hour

-

Instalation:

-

Engineer Guide

Quick Details

-

Place of Origin:

-

HEN

-

Effective Volume:

-

15CBM

-

Dimension(L*W*H):

-

2.3*2.**2.9

-

Voltage:

-

Customize

-

Weight (KG):

-

8500

-

Raw material:

-

Coconut Shell

-

Final product:

-

Coconut Shell Charcoal

-

Final product usage:

-

Make Charcoal Briquettes

-

Color:

-

Customer's Request

-

Carbonization time:

-

30 hour

-

Instalation:

-

Engineer Guide

Products Description

Introduction to Activated Carbon Regeneration

At present, activated carbon has been widely used in environmental protection, industry and civil use, and has achieved considerable results. However, after activated carbon is replaced by adsorption saturation, the user units discard it, bury it or burn it, resulting in waste of resources and damage to the environment. re-pollution of the environment.

Activated carbon adsorption is a physical process, so high-temperature steam can also be used to desorb the impurities in the used activated carbon and restore its original activity to achieve the purpose of repeated use, which has obvious economic benefits.

The purpose of the regenerated activated carbon can still be reused and regenerated continuously.

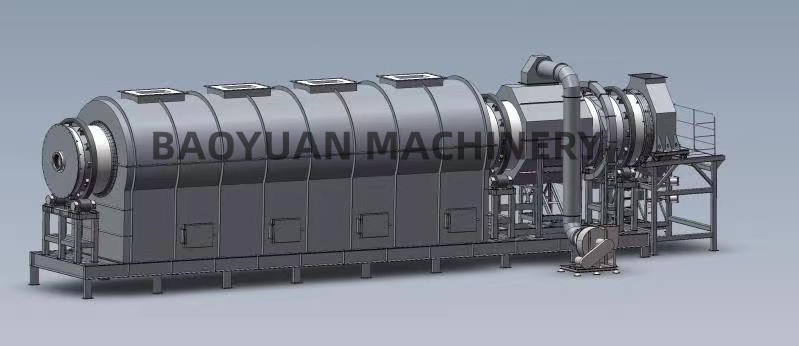

Technical Parameters

|

Capacity

|

5-40t/d

|

|

Regeneration rate

|

50-110%

|

|

Types of Activated Carbon

|

Granular Activated Carbon/Powder Activated Carbon

|

|

Treatment method

|

High temperature steam regeneration method

|

|

Heating method

|

Internal heat/External heat

|

|

Activator

|

Water steam

|

|

Properties of waste activated carbon

|

Solid waste activated carbon/Hazardous waste activated carbon

|

|

Waste gas treatment method

|

Secondary combustion, Deacidification, Dust removal, Adsorption, Washing

|

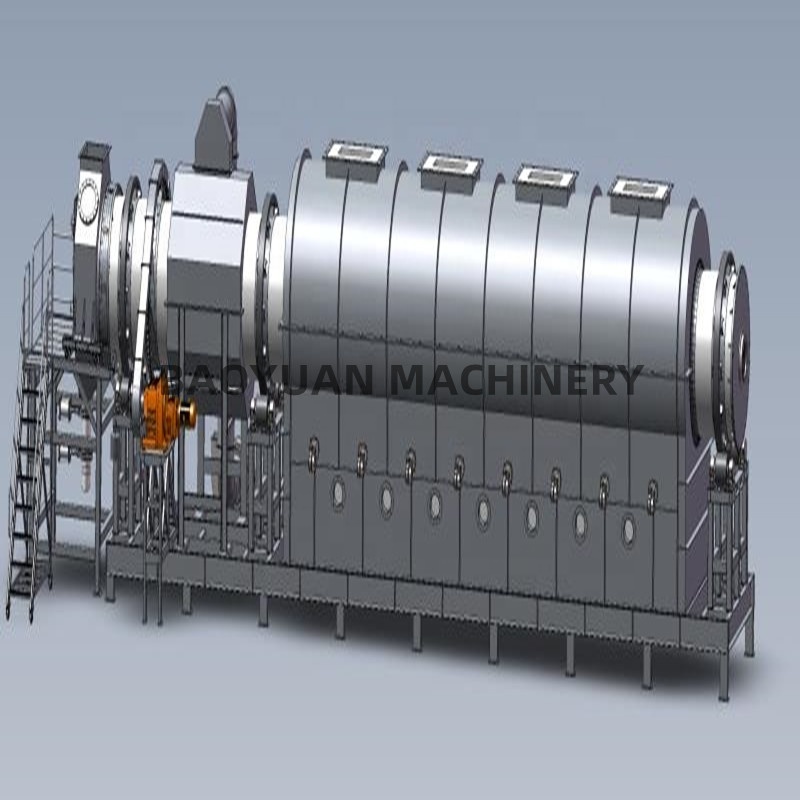

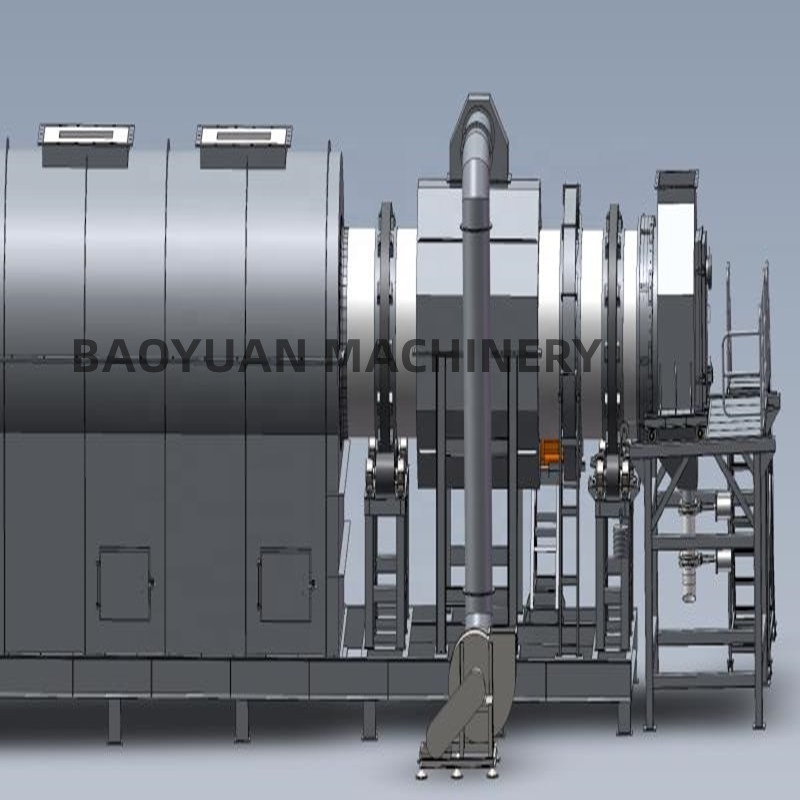

Introduction of activated carbon regeneration equipment

The activated carbon regeneration equipment produced by our factory adopts the thermal regeneration method, which is the most widely used and industrially mature activated carbon regeneration method. During the regeneration process of dehydrated activated carbon, according to the change of organic matter when heated to different temperatures, it is generally divided into three stages: drying, high-temperature carbonization and activation. In the drying stage, the volatile components on the activated carbon are mainly removed. In the high-temperature carbonization stage, a part of the organic matter adsorbed on the activated carbon is boiled, vaporized and desorbed, and a part of the organic matter undergoes a decomposition reaction to generate small molecule hydrocarbons. At this stage, the temperature will reach 800~900°C. The activation process is that activated carbon reacts with water vapor in an atmosphere of water vapor, burns off part of the carbon, reopens the micropores, and restores activity.

The exhaust gas generated during the regeneration of activated carbon is treated by secondary combustion, dry/semi-dry/wet washing, dust removal, etc., which can remove harmful components of organic matter, nitrogen oxides, acids, dioxins, and dust in the exhaust gas , to achieve exhaust emission standards.

The activated carbon regeneration equipment produced by our factory adopts the thermal regeneration method, which is the most widely used and industrially mature activated carbon regeneration method. During the regeneration process of dehydrated activated carbon, according to the change of organic matter when heated to different temperatures, it is generally divided into three stages: drying, high-temperature carbonization and activation. In the drying stage, the volatile components on the activated carbon are mainly removed. In the high-temperature carbonization stage, a part of the organic matter adsorbed on the activated carbon is boiled, vaporized and desorbed, and a part of the organic matter undergoes a decomposition reaction to generate small molecule hydrocarbons. At this stage, the temperature will reach 800~900°C. The activation process is that activated carbon reacts with water vapor in an atmosphere of water vapor, burns off part of the carbon, reopens the micropores, and restores activity.

The exhaust gas generated during the regeneration of activated carbon is treated by secondary combustion, dry/semi-dry/wet washing, dust removal, etc., which can remove harmful components of organic matter, nitrogen oxides, acids, dioxins, and dust in the exhaust gas , to achieve exhaust emission standards.

Product Application

Raw materials

seeds;

shells and pits of tree-fruits;

wood chips;

bamboo;

shrubby and other plant materials, the fraction of which is from 5 to 30 mm with a moisture content of not more than 15%.

|

Coconut shell

|

Walnut shell

|

Hazelnut shell

|

Wood chips

|

Bamboo

|

|

Coconut shell charcoal

|

Shell charcoal

walnut

|

Hazelnut shell charcoal

|

Wood chips charcoal

|

Bamboo charcoal

|

|

Palm kernel shell

|

Pits of olives

|

Pits of date

|

Peach Shell

|

Hawthorn Seed

|

|

Palm kernel charcoal

|

Pits of olives charcoal

|

Pits of date charcoal

|

Peach Shell charcoal

|

Hawthorn Seed charcoal

|

Received products

Raw materials for obtaining activated carbon

Raw Material for BBQ Charcoal Briquette and Industry

Raw materials for the production of coal briquettes for hookahs (hookah, hookah coal)

BIO-Char, as a fertilizer or hydroponic growth intended for the agricultural industry, is made from plant raw materials and does not contain harmful substances.

Hot Searches