- Product Details

- {{item.text}}

Quick Details

-

Brand name:

-

HDT

-

Weight:

-

About 1550g/sqm

-

Thickness:

-

Approx 15 Mm

-

Logo:

-

Accept Customized Logo

-

OEM/ODM:

-

Accepet

-

Age Group:

-

Adult

Quick Details

-

Material:

-

Polyester

-

Technics:

-

MACHINE MADE

-

Place of Origin:

-

Tianjin

-

Brand name:

-

HDT

-

Weight:

-

About 1550g/sqm

-

Thickness:

-

Approx 15 Mm

-

Logo:

-

Accept Customized Logo

-

OEM/ODM:

-

Accepet

-

Age Group:

-

Adult

Specification

|

Product Name

|

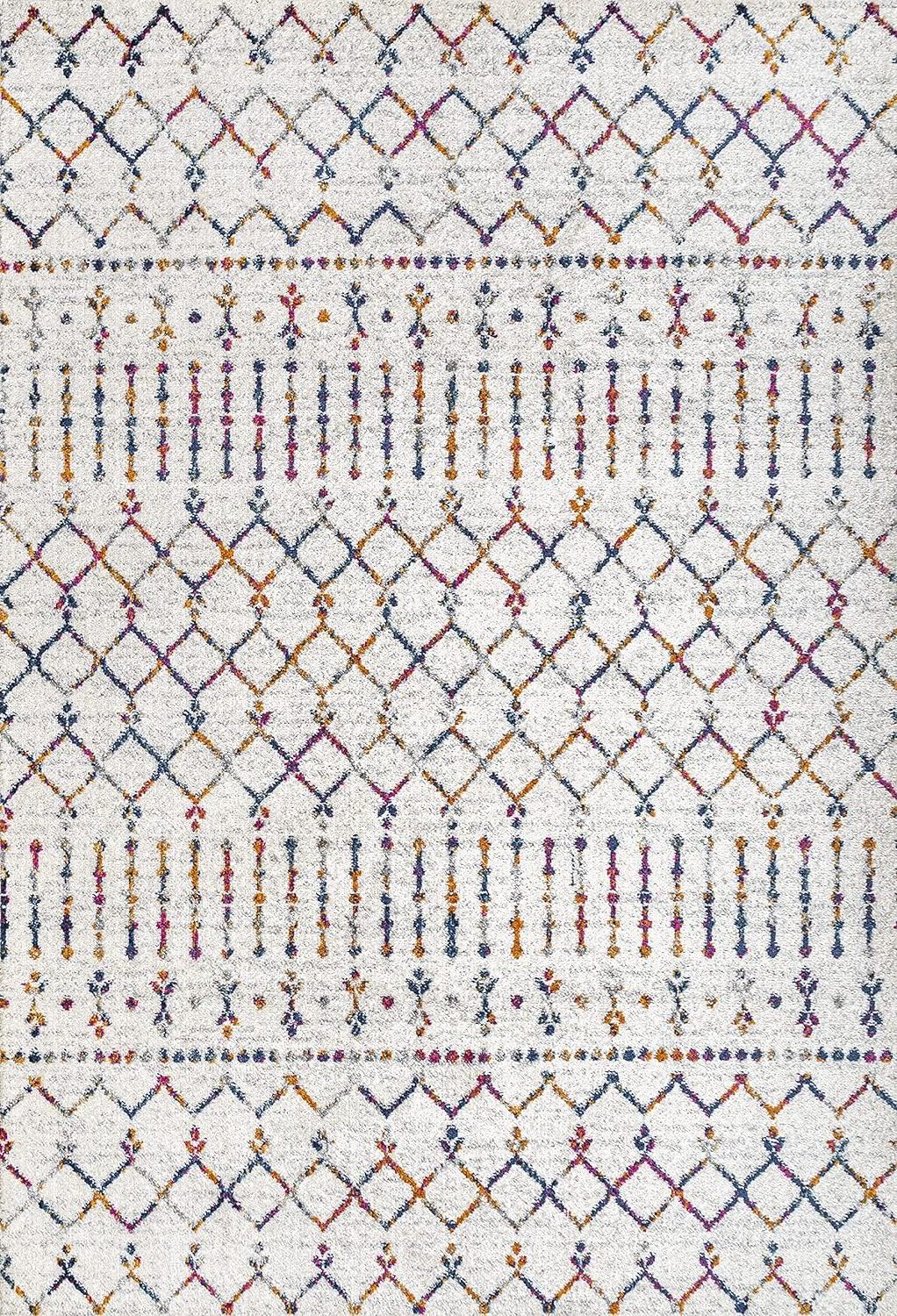

customised berber rug acoustic flooring smoothedge mats bedside sound deadening carpet underlay trim for house bed room

|

|

Material

|

100% Polyester

|

|

Packing

|

1 pcs per size/ roll with transparent PE bag outside

|

|

Delivery Time

|

Below 50000sqm, deliver in 7 days

|

|

Backing

|

None slip dotted backing

|

|

Technical

|

3D Digital Printed carpet

|

|

Size of carpet

|

Maxium 2 meter width, like 50cm*80cm/90cm*130cm/130cm*180cm/140com*200cm/ 160cm*210cm/200cm*300cm or Customer Request

|

|

Thickness

|

Approx 15mm

|

|

Weight/Sqm

|

1500GSQ+

|

Products Description

The Surface

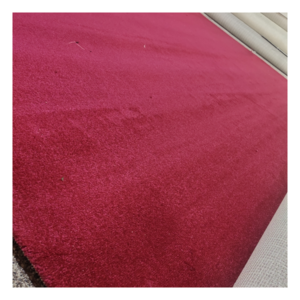

We use more than 850 gsm per sqm surface crystal velvet fabric, it`s the best in the market. Quality can be seen!

Softness can be feel!

The overlocking

Special machine, with special new over locking wire, makes the carpet durable and pleasant.

The weight

The Backing

White dotted backing design brings it great reaction on non slip function

Scene Display

Manufacturing Technique

1ST STEP: PRINTING

Print customer needed designs, total we have 16 sets of 8 heads fast printing machine.

2ND STEP: HEAT TRANSFER

250℃ high temperature machine to transfer the printed designs on carpet raw materials.

3RD STEP: CUTTING

Cut the carpet rolls into pieces based on customer requirements.

4TH STEP:OVERLOCKING

Overlock the cutting surface with strong and thick wire. Total we have 40 sets overlocking machines.

Hot Searches