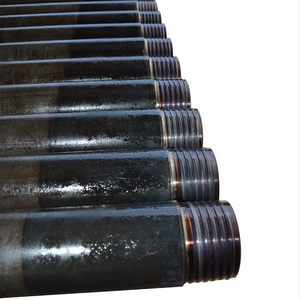

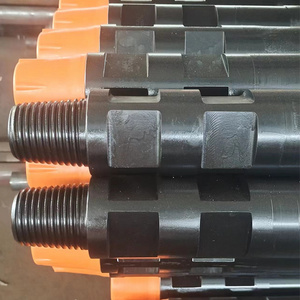

Water well drill pipe is a kind of drilling tool that uses alloy steel pipe to thicken the upsetting at both ends, and connect

with tool joints by friction welding. The quality of the drill pipe mainly depends on the selection of materials and the strength

of the joint thread. Good materials are not easy to bend or break due to fatigue. The dense tissue after the end upsetting can

effectively improve its mechanical properties and strength of the connection. Features: 1. The rod material of the drill pipe is

made of STM-R780 material, which has stable and reliable performance. The end is heated by intermediate frequency, hydraulically

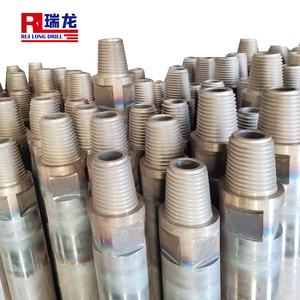

upset, and heat treated, which effectively eliminates the internal stress of pre-processing. 2. The tool joints are made of

42CrMoA material, which is quenched and tempered after rough machining, and subjected to surface nitriding treatment after

finishing. 3. The threads are all cut and formed by CNC lathe forming inserts, with precise coordination and strong

interchangeability.

- Product Details

- {{item.text}}

Quick Details

-

Local Service Location:

-

None

-

Length:

-

50mm~72mm

-

Application:

-

Water well

Quick Details

-

Weight (KG):

-

500

-

Place of Origin:

-

ZHE

-

Brand Name:

-

duote

-

Local Service Location:

-

None

-

Length:

-

50mm~72mm

-

Application:

-

Water well

Products Description

Drill pipe

|

Model

|

Wall Thickness

(mm) |

Effective Length

(mm) |

Connection Type

|

Joints Length

(mm) |

Marks

|

|

Φ64

|

4.8

|

1500/2000/3000

|

2-3/8 REG

|

170/170

|

|

|

Φ76

|

4

|

1500/2000/3000

|

2-3/8 REG

|

190/190

|

|

|

Φ76

|

5

|

1500/2000/3000

|

2-3/8 REG

|

190/190

|

|

|

Φ76

|

6.5

|

1500/2000/3000

|

2-3/8 REG

|

190/190

|

|

|

Φ89

|

5.5

|

1000/1500/2000

3000/4000/5000 |

2-3/8 REG

|

200/200

|

|

|

Φ89

|

6.5

|

1000/1500/2000

3000/4000/5000 |

2-3/8 REG

|

200/200

|

|

|

Φ89

|

6.5

|

1000/1500/2000

3000/4000/5000 |

NC26

|

280/200

|

Double Wrench Flat

|

|

Φ102

|

8.5

|

1000/1500/2000

3000/4000/4500 |

NC31

|

230/230

|

|

|

Φ102

|

8.5

|

1000/1500/2000

3000/4000/4500 |

NC31

|

300/300

|

Double Wrench Flat

|

|

Φ114

|

8.5

|

1500/2000/3000

4000/4500/5000 |

NC35

|

230/230

|

|

|

Φ114

|

8.5

|

1500/2000/3000

4000/4500/5000 |

NC35

|

300/300

|

Double Wrench Flat

|

|

Φ127

|

9

|

1500/2000/3000

4000/5000 |

NC38

|

240/240

|

|

|

Φ127

|

9

|

1500/2000/3000

4000/5000 |

NC38

|

320/320

|

Double Wrench Flat

|

Water well drill pipe is a kind of drilling tool that uses alloy steel pipe to thicken the upsetting at both ends, and connect

with tool joints by friction welding. The quality of the drill pipe mainly depends on the selection of materials and the strength

of the joint thread. Good materials are not easy to bend or break due to fatigue. The dense tissue after the end upsetting can

effectively improve its mechanical properties and strength of the connection. Features: 1. The rod material of the drill pipe is

made of STM-R780 material, which has stable and reliable performance. The end is heated by intermediate frequency, hydraulically

upset, and heat treated, which effectively eliminates the internal stress of pre-processing. 2. The tool joints are made of

42CrMoA material, which is quenched and tempered after rough machining, and subjected to surface nitriding treatment after

finishing. 3. The threads are all cut and formed by CNC lathe forming inserts, with precise coordination and strong

interchangeability.

with tool joints by friction welding. The quality of the drill pipe mainly depends on the selection of materials and the strength

of the joint thread. Good materials are not easy to bend or break due to fatigue. The dense tissue after the end upsetting can

effectively improve its mechanical properties and strength of the connection. Features: 1. The rod material of the drill pipe is

made of STM-R780 material, which has stable and reliable performance. The end is heated by intermediate frequency, hydraulically

upset, and heat treated, which effectively eliminates the internal stress of pre-processing. 2. The tool joints are made of

42CrMoA material, which is quenched and tempered after rough machining, and subjected to surface nitriding treatment after

finishing. 3. The threads are all cut and formed by CNC lathe forming inserts, with precise coordination and strong

interchangeability.

FAQ

Q2: Can you send products to my country?

A2: Sure, we can. If you do not have your own ship forwarder, we can help you.

Q3: Can you do OEM for me?

A3: We accept all OEM orders,just contact us and give me your design.we will offer you a reasonable price and make samples for you

ASAP.

Q4: What's your payment terms ?

A4: By T/T,LC AT SIGHT,30% deposit in advance, balance 70% before shipment.

Q5: How can I place the order?

A5: First sign the PI,pay deposit,then we will arrange the production.After finished production need you pay balance. Finally we

will ship the Goods.

Q6: When can I get the quotation ?

A6: We usually quote you within 24 hours after we get your inquiry. If you are very urgent to get the quotation.Please call us or

tell us in your mail, so that we could regard your inquiry priority.

A2: Sure, we can. If you do not have your own ship forwarder, we can help you.

Q3: Can you do OEM for me?

A3: We accept all OEM orders,just contact us and give me your design.we will offer you a reasonable price and make samples for you

ASAP.

Q4: What's your payment terms ?

A4: By T/T,LC AT SIGHT,30% deposit in advance, balance 70% before shipment.

Q5: How can I place the order?

A5: First sign the PI,pay deposit,then we will arrange the production.After finished production need you pay balance. Finally we

will ship the Goods.

Q6: When can I get the quotation ?

A6: We usually quote you within 24 hours after we get your inquiry. If you are very urgent to get the quotation.Please call us or

tell us in your mail, so that we could regard your inquiry priority.

Hot Searches

![High quality used water well drill pipe for oil field drilling [need to customize]](https://cdn.bestsuppliers.com/seo_products_img/yudrill/3f4593d7ec79388aba43f91dbc735d66.jpg!/rotate/180/sq/300)