- Product Details

- {{item.text}}

Quick Details

-

Operating Speed:

-

18000-24000rpm

-

Voltage:

-

220V/380V

-

Frequency:

-

400-800Hz

-

Rotating speed:

-

18000-24000rpm

-

Current:

-

14.5A

-

Tool handle model:

-

BT30

-

Spindle diameter:

-

125mm

-

Power:

-

2.2/4.5/5.5/7.5/11kw

-

After Warranty Service:

-

Online support

Quick Details

-

Place of Origin:

-

Shandong, China

-

Weight (KG):

-

36

-

Brand Name:

-

LIHAN

-

Operating Speed:

-

18000-24000rpm

-

Voltage:

-

220V/380V

-

Frequency:

-

400-800Hz

-

Rotating speed:

-

18000-24000rpm

-

Current:

-

14.5A

-

Tool handle model:

-

BT30

-

Spindle diameter:

-

125mm

-

Power:

-

2.2/4.5/5.5/7.5/11kw

-

After Warranty Service:

-

Online support

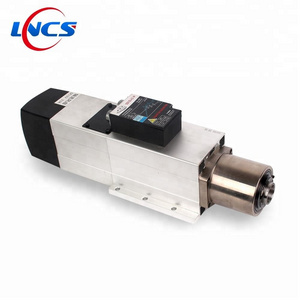

2.2/3/4.5/ 5.5/7.5kw 24000rpm bt30 water cooled cnc machine small

automatic tool changer autochanger atc spindle motor

Product Description

Features:

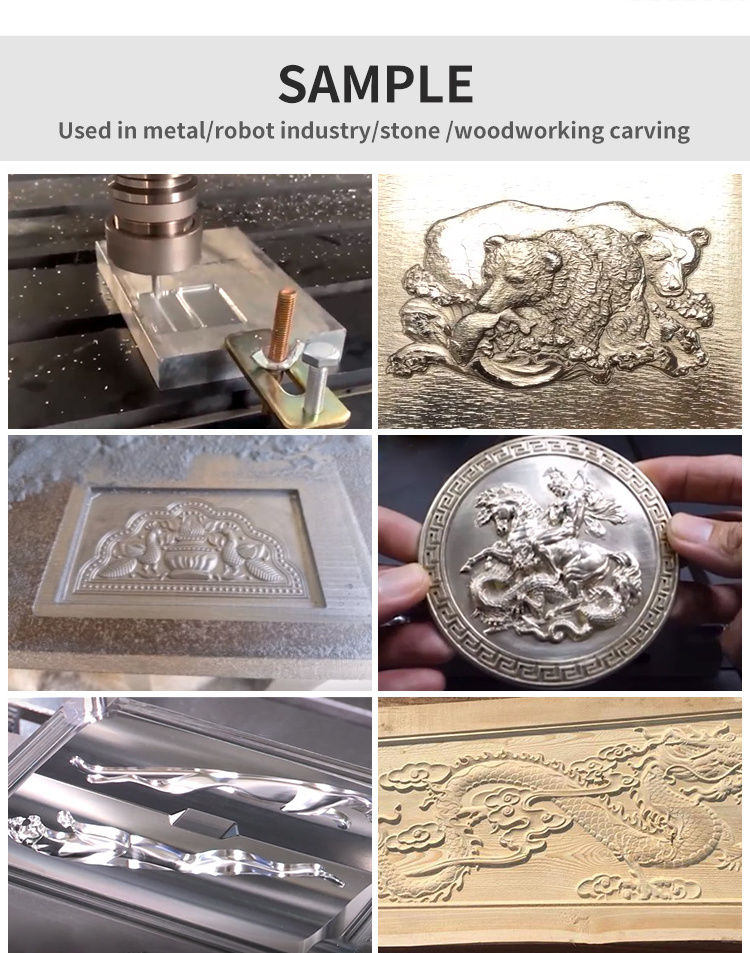

1.This series of spindles are mainly used in mold processing, metal processing, stone processing, woodworking processing and other fields.

2.The spindle power covers2.2kw-11kw, with a maximum speed of 24,000 RPM.

3.This type spindle can be cooled by water or oil.

4. It is characterized by compact structure, light weight, low inertia, low vibration and low noise.

2.The spindle power covers2.2kw-11kw, with a maximum speed of 24,000 RPM.

3.This type spindle can be cooled by water or oil.

4. It is characterized by compact structure, light weight, low inertia, low vibration and low noise.

Product Paramenters

|

Model

|

80-20-30Z/2.2

|

110-30-18Z/4.5

|

110-30-24Z/4.5

|

120-30-24Z/5.5

|

120-30-18Z/5.5

|

125-30-18Z/7.5

|

125-30-24Z/7.5

|

150-40-12Z/11

|

150-40-15Z/11

|

|

Power

|

2.2kw

|

4.5kw

|

4.5kw

|

5.5kw

|

5.5kw

|

7.5kw

|

7.5kw

|

11kw

|

11kw

|

|

Spindle net weight

|

13kg

|

13kg

|

13kg

|

23kg

|

23kg

|

46kg

|

46kg

|

46kg

|

46kg

|

|

Spindle diameter

|

100mm

|

110mm

|

110mm

|

120mm

|

120mm

|

125mm

|

125mm

|

150mm

|

150mm

|

|

Tool handle model

|

ISO20

|

BT30

|

BT30

|

BT30

|

BT30

|

BT30

|

BT30

|

BT40

|

BT40

|

|

Current

|

8.9A

|

11A

|

11A

|

14.5A

|

14.5A

|

15.6A

|

15.6A

|

22A

|

22A

|

|

Voltage

|

220V

|

380V

|

380V

|

380V

|

380V

|

380V

|

380V

|

380V

|

380V

|

|

Frequency

|

1000Hz

|

600Hz

|

800Hz

|

800Hz

|

600Hz

|

900Hz

|

1200Hz

|

600Hz

|

750Hz

|

|

Rotating speed

|

30000

rpm

|

18000

rpm

|

24000

rpm

|

24000

rpm

|

18000

rpm

|

9000-18000

rpm

|

9000-24000

rpm

|

9000-12000

rpm

|

9000-15000

rpm

|

APPLICATIONS

Product Detail

Product safety precautions:

* Personal safety

1. Before starting the spindle, please keep the spindle in the state of emergency stop at any time

2. During the operation of the spindle, please do not touch its rotating part. Take necessary protective measures to avoid the spindle directly facing the operator or other personnel.

3. If the power supply is restored after an instantaneous power failure during operation, the spindle may suddenly start again,so do not get close to it to avoid accidents.

4. After power is turned off, do not touch the wiring position of the power connection while the spindle is still in the state

of rotation

5. Please do not set, disassemble or repair the spindle for non-designated personnel.

* Product safety

1.Spindle is a high speed, precise integration of mechanical and electrical components, for the correct and safe use of the

spindle, please carefully read the instructions and precautions before use.

2.The storage temperature of the motorized spindle is 20±10°C, the humidity is 85%, and the maximum storage time is three months.

3.Before starting the spindle, first connect the coolant, during the rotation, do not allow to break the coolant, otherwise it

will damage the spindle parts.

4.Special disassembly tools should be used when removing the chuck.

5.When installing the spindle, do not clamp the body too tightly to avoid internal parts damage caused by deformation of the body.

6.Do not overspeed the spindle, and adjust the operating parameters according to the range in the technical parameters table.

7.When the spindle is newly installed or has not been used for a long time, it is forbidden to run at the maximum speed of the spindle when starting up. It should run at a low speed for 5-10 minutes and then rise to the working speed.

8.Do not disassemble and operate the spindle without training personnel.

2. During the operation of the spindle, please do not touch its rotating part. Take necessary protective measures to avoid the spindle directly facing the operator or other personnel.

3. If the power supply is restored after an instantaneous power failure during operation, the spindle may suddenly start again,so do not get close to it to avoid accidents.

4. After power is turned off, do not touch the wiring position of the power connection while the spindle is still in the state

of rotation

5. Please do not set, disassemble or repair the spindle for non-designated personnel.

* Product safety

1.Spindle is a high speed, precise integration of mechanical and electrical components, for the correct and safe use of the

spindle, please carefully read the instructions and precautions before use.

2.The storage temperature of the motorized spindle is 20±10°C, the humidity is 85%, and the maximum storage time is three months.

3.Before starting the spindle, first connect the coolant, during the rotation, do not allow to break the coolant, otherwise it

will damage the spindle parts.

4.Special disassembly tools should be used when removing the chuck.

5.When installing the spindle, do not clamp the body too tightly to avoid internal parts damage caused by deformation of the body.

6.Do not overspeed the spindle, and adjust the operating parameters according to the range in the technical parameters table.

7.When the spindle is newly installed or has not been used for a long time, it is forbidden to run at the maximum speed of the spindle when starting up. It should run at a low speed for 5-10 minutes and then rise to the working speed.

8.Do not disassemble and operate the spindle without training personnel.

Customer Feedback

Certifications

Product Packaging

FAQ

1.About us

We are in Jinan, Shan Dong, which is the hometown of CNC Router. We are focus on CNC Machine Parts.

We've been in this business for more than 10 years.

2.What products do we have?

We have many CNC Machine Parts , include Spindle,Inverter,stepper motor,driver,guide rail,sliding block,

rack,gear box,water pump,dust collector,coupling,tool-setter,tool cutter. And so on ...

3.How we guarantee the quality of the products?

Each batch of products will pass the test before leaving the factory.

Before delivery, we will check the list one by one.

4.Why you should choose us?

We are focus on CNC Router Parts more than 10years. We can provide you with the overall solution, We

can offer you many type CNC products.Just tell us which you need , we will provide you as the best price

and the best quality and service.

5.What's the payment term ?

We normally accept T/T, Western Union, L/C, and Paypal.

6.What about the shipping ?

We support multiple modes of transportation,such as by express,by air,by sea,by rail and so on.

Also can shipping by DHL\FedEx\TNT\UPS\EMS and so on.

We can offer different type transactions: FOB\EXW\FCA\DAP\CIF.

We can also help you to keep other suppliers goods at our warehouse and shipping together.

7.How to place an order ?

Just tell us what you need , then we can make a Invoice for you. If all OK , then make the order and we

shipping to you the goods ASAP.In order to ensure that all products are what you need, we will show you the pictures, drawings, videos

and so on before shipping .

8.What about the delivery time ?

We have a large warehouse and most of our goods are in stock.When you have order, we can shipping

the goods fast.Generally speaking, the time from our warehouse to the forwarder is about two days, and then the goods

can be sent by DHL FedEx UPS TNT to you.

We are in Jinan, Shan Dong, which is the hometown of CNC Router. We are focus on CNC Machine Parts.

We've been in this business for more than 10 years.

2.What products do we have?

We have many CNC Machine Parts , include Spindle,Inverter,stepper motor,driver,guide rail,sliding block,

rack,gear box,water pump,dust collector,coupling,tool-setter,tool cutter. And so on ...

3.How we guarantee the quality of the products?

Each batch of products will pass the test before leaving the factory.

Before delivery, we will check the list one by one.

4.Why you should choose us?

We are focus on CNC Router Parts more than 10years. We can provide you with the overall solution, We

can offer you many type CNC products.Just tell us which you need , we will provide you as the best price

and the best quality and service.

5.What's the payment term ?

We normally accept T/T, Western Union, L/C, and Paypal.

6.What about the shipping ?

We support multiple modes of transportation,such as by express,by air,by sea,by rail and so on.

Also can shipping by DHL\FedEx\TNT\UPS\EMS and so on.

We can offer different type transactions: FOB\EXW\FCA\DAP\CIF.

We can also help you to keep other suppliers goods at our warehouse and shipping together.

7.How to place an order ?

Just tell us what you need , then we can make a Invoice for you. If all OK , then make the order and we

shipping to you the goods ASAP.In order to ensure that all products are what you need, we will show you the pictures, drawings, videos

and so on before shipping .

8.What about the delivery time ?

We have a large warehouse and most of our goods are in stock.When you have order, we can shipping

the goods fast.Generally speaking, the time from our warehouse to the forwarder is about two days, and then the goods

can be sent by DHL FedEx UPS TNT to you.

Hot Searches