- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Sevenstars

-

Application:

-

PET bottle Recycling

-

Production Capacity (kg/h):

-

300 - 3000

-

Voltage:

-

380V/3phase/50Hz(customized)

-

Dimension(L*W*H):

-

4000*1800*3800mm

-

Power (kW):

-

75-250

-

Weight (T):

-

15

-

machine name:

-

PET bottle recycling machine

-

PET flakes Moisture:

-

less than 1%

-

PET flake final Particle size:

-

16-20mm

-

PVC content:

-

less than 50ppm

-

PE/PE and Paper and other impurity:

-

-

metal content:

-

<50ppm

-

Ph-value:

-

Neutral

-

melting point:

-

245-250

-

IV of PET flake:

-

0.74-0.78

-

Water consumption:

-

10Ton/h

-

Marketing Type:

-

New Product 2020

Quick Details

-

Machine Type:

-

PET Bottle Washing Line

-

Max.Production Capacity (kg/h):

-

3000

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sevenstars

-

Application:

-

PET bottle Recycling

-

Production Capacity (kg/h):

-

300 - 3000

-

Voltage:

-

380V/3phase/50Hz(customized)

-

Dimension(L*W*H):

-

4000*1800*3800mm

-

Power (kW):

-

75-250

-

Weight (T):

-

15

-

machine name:

-

PET bottle recycling machine

-

PET flakes Moisture:

-

less than 1%

-

PET flake final Particle size:

-

16-20mm

-

PVC content:

-

less than 50ppm

-

PE/PE and Paper and other impurity:

-

-

metal content:

-

<50ppm

-

Ph-value:

-

Neutral

-

melting point:

-

245-250

-

IV of PET flake:

-

0.74-0.78

-

Water consumption:

-

10Ton/h

-

Marketing Type:

-

New Product 2020

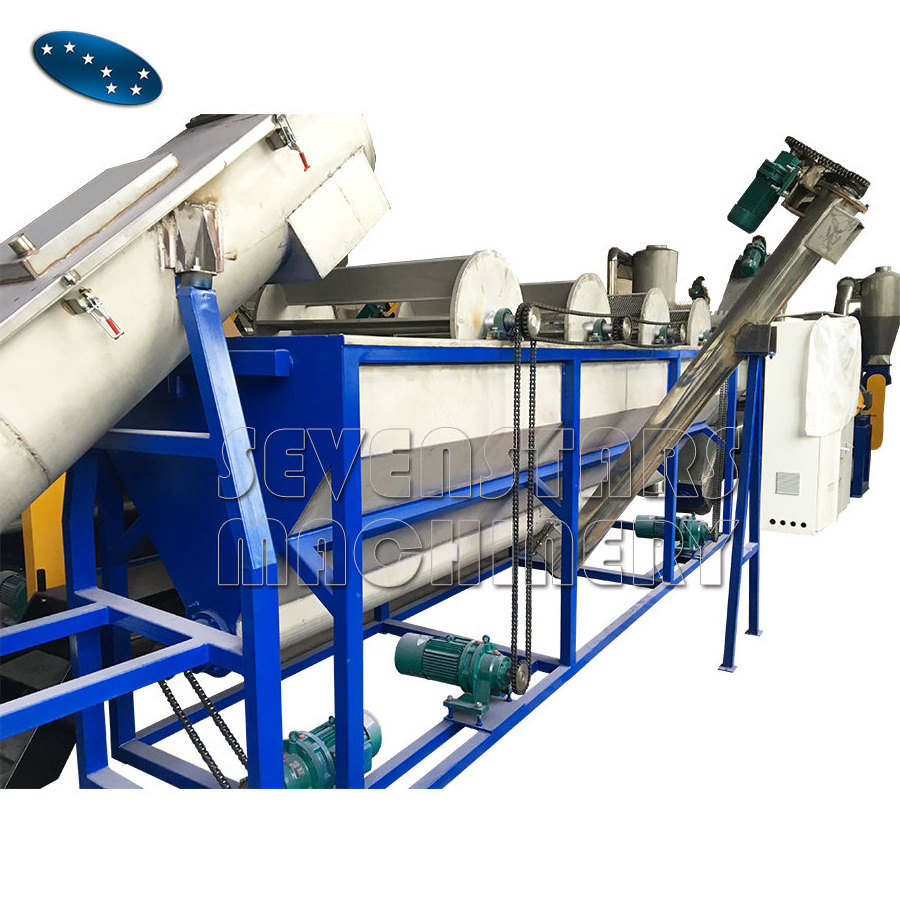

Products Show

Our company can provide a wide range of standard and bespoke plastic crushing and washing systems to meet the ever changing and demanding requirements of a modern recycling environment. The systems are capable of processing a wide range of plastic materials with varying levels of contamination including extremely heavy contamination such as oil based substances and agricultural waste.

The output material can be applied for granulation, blow molding and blowing injection. The whole production line is easy to operate, efficient and low energy consumption.

PP PE film washing recycling machine is widely used for washing and recycling waste PE film and PP woven bags,non-woven bag. This line can separate muds, sands and other impurities from films and bags easily. The whole production line is automatic controlling, compact process. it can process capacity up to 1000 kg/h, the out products can be applied for granulation.

The output material can be applied for granulation, blow molding and blowing injection. The whole production line is easy to operate, efficient and low energy consumption.

PP PE film washing recycling machine is widely used for washing and recycling waste PE film and PP woven bags,non-woven bag. This line can separate muds, sands and other impurities from films and bags easily. The whole production line is automatic controlling, compact process. it can process capacity up to 1000 kg/h, the out products can be applied for granulation.

Product Description

|

Model

|

Capacity(kg/h)

|

Length(M)

|

working way

|

|

PET300

|

300

|

25

|

Automatic

|

|

PET500

|

500

|

25

|

Automatic

|

|

PET1000

|

1000

|

35

|

Automatic

|

|

PET1500

|

1500

|

35

|

Automatic

|

|

PET2000

|

2000

|

40

|

Automatic

|

|

PET3000

|

3000

|

50

|

Automatic

|

|

PET4000

|

4000

|

65

|

Automatic

|

|

PET5000

|

5000

|

80

|

Automatic

|

|

PET6000

|

6000

|

90

|

Automatic

|

Raw material & formulation:

Post-consumer PET bottles

Warehouse/Workshop:

About 1000 square meters with height 7 meters

Water supply: Consumption: 6-7ton/h(but it can recycled use

Note : 1) water consumption of the line depend on the installed components ,the contamination of the imput material and the installed water filter and water treatment system

2) to reduce the water consumption ,we recommend to install a water treatment plant , by using press filter ,the load of waste water could be further minimized , the buyer should provide water tank (we recommend ground tank)with level indicator and water pumps and valves

Water supply: Consumption: 6-7ton/h(but it can recycled use

Note : 1) water consumption of the line depend on the installed components ,the contamination of the imput material and the installed water filter and water treatment system

2) to reduce the water consumption ,we recommend to install a water treatment plant , by using press filter ,the load of waste water could be further minimized , the buyer should provide water tank (we recommend ground tank)with level indicator and water pumps and valves

Product Paramenters

|

item

|

value

|

|

Application

|

PET bottle Recycling

|

|

Condition

|

New

|

|

Place of Origin

|

China

|

|

|

Jiangsu

|

|

Automatic Grade

|

Automatic

|

|

Brand Name

|

Sevenstars

|

|

Plastic Type

|

PET

|

|

Production Capacity (kg/h)

|

|

|

Machine Type

|

PET Bottle Washing Line

|

|

Equipment List

|

Trommer, Pre-washer, Bale Opener, Dewatering Machine, Floating Washing Tank, Hot Air Dryer, Frication Washer, Label Separator, Label Remover, Hot Washing Tank

|

|

Max.Production Capacity (kg/h)

|

3000

|

|

Voltage

|

380V/3phase/50Hz(customized)

|

|

Dimension(L*W*H)

|

4000*1800*3800mm

|

|

Power (kW)

|

75-250

|

|

Weight (T)

|

15

|

|

Certification

|

CE ISO

|

|

Warranty

|

1.5 years

|

|

After-sales Service Provided

|

Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support

|

|

Key Selling Points

|

High Productivity

|

|

Video outgoing-inspection

|

Provided

|

|

Applicable Industries

|

Manufacturing Plant

|

|

After Warranty Service

|

Video technical support, Online support, Spare parts, Field maintenance and repair service

|

|

Local Service Location

|

Egypt, Turkey, Brazil, Saudi Arabia, Russia, Thailand, Romania, South Africa, Ukraine

|

|

Showroom Location

|

Egypt, Turkey, Brazil, India, Mexico, Russia, Thailand, Romania, Ukraine

|

|

Machinery Test Report

|

Provided

|

|

Marketing Type

|

New Product 2020

|

|

Warranty of core components

|

1.5 years

|

|

Core Components

|

PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

|

|

machine name

|

PET bottle recycling machine

|

|

PET flakes Moisture

|

less than 1%

|

|

PET flake final Particle size

|

16-20mm

|

|

PVC content

|

less than 50ppm

|

|

PE/PE and Paper and other impurity

|

|

|

metal content

|

<50ppm

|

|

Ph-value

|

Neutral

|

|

melting point

|

245-250

|

|

IV of PET flake

|

0.74-0.78

|

|

Water consumption

|

10Ton/h

|

Hot Searches