Provide the best factory building support and machine design technical support,

and after-sale support machine usage guide instruction, and field video guide.

If necessary we can send professional technicians there.

- Product Details

- {{item.text}}

Quick Details

-

maximum the size:

-

200mmx100mmxL6500mm

-

standard work piece weight:

-

3.5KG

-

standard work piece surface on average:

-

1.2㎡/piece

-

the standard speed of conveying chain:

-

1.2-1.5m/min

-

Certification:

-

CE ISO

Quick Details

-

Machine Type:

-

powder coating machine

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Giansun

-

maximum the size:

-

200mmx100mmxL6500mm

-

standard work piece weight:

-

3.5KG

-

standard work piece surface on average:

-

1.2㎡/piece

-

the standard speed of conveying chain:

-

1.2-1.5m/min

-

Certification:

-

CE ISO

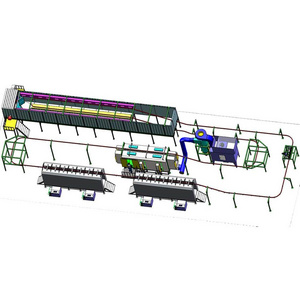

Automatic Vertical Powder Coating Production Line

Product Description

Project design basis

1、design data

A、coating material: aluminum profile

B、 process description

a、loading, pretreatment, water drying, powder coating, curing, unloading.

C、coating profiles:

1. maximum the size: 200mm×100mm×L6500mm

2. standard work piece weight: 3.5KG

3. standard work piece surface on average:1.2㎡/支

4. the standard speed of conveying chain : 1.2-1.5m/min(0.8m/min-3.5m/min adjustable)

2、 energy supply

A、liquified petroleum gas 、pipeline gas

B、water vapor

3、compress air

A、pressure:7.0bar

B、maximum quantity of steam:1.2g/nm3

C、Maximum quantity of oil:0.02ppm

D、:9.7m3/min

D、Maximum flow of compressed air:9.7m3/min

4、industry water

A、 pressure:3+0.2bar

B、 flow:5m3/h

5、deionized water rinse

A、electric conductivity:10us/cm

B、flow: 3m3/h

6、powder coating

A、characteristics of powder:LEL≥40g/Nm3

7、the space of hanging material:66mm、100mm、133mm、200mm

8、reference output:

A、standard speed of the coating chain:1.3m/min

Every hour spraying quantity: 1300mm/min÷100mm/piece×60min=780 pieces

Every hour spraying weight: 780 pieces×3.5kilogram/piece =2.73tons

monthly output:2.73 tons ×20 hours/day ×26/month =1419 tons/month

Our vertical line advantage brief

Equipment Name

What we use

What other factories use

Our advantage

1

pretreatment

Wall material

+PVC

Stainless steel+PVC anticorrossive system

Stainless steel

Stainless steel+PVC anticorrossive system has stronger ani ecrossion with longer life.

Waterfall equipment

Stable pressure water pump + duck mouth faucet

Basin

The water with chemical fall down more stably and smoothly and make profile cleaning better.

Water Pump

Horizontal fluoroplastics pump or Alloy pump

Alloy pump

fluoroplastics pump: outside is metal,inside is fluoroplastics , be suitable for -85~150℃ corrosive material, it is the most

advanced anti-corrosive in the world .It has longer life than alloy pump.

2

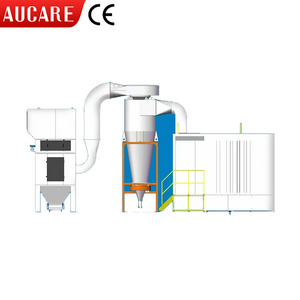

Powder coating booth

The third generation V shaped booth + PE double side recycling belt(automatic cleaning self)

The first generation V shaped booth +polythene film recycling belt

Or the second generation U shaped Booth+ PE recycling belt

Our third generation booth : no powder overflow,

Powder recycling can be done just by a vacuum pump.

The energy consumption is better than the first generation and second generation one. Morever ,it is more easily to clean and

shorten the cleaning time. Our PE belt can be recycling use and save cost from long term.

The first recycling system

Big cyclone

Big cyclone

Our recycling rate is more than 97%. Can save 1-2kg powder per ton profile basis on the common used powder

Filtering system

Filtering bag filtering system

Filtering bag filtering system

Reciprocator

The running rail use real lift rail.

The wheel use polyurethane.

Use digital frequency conversion to adjust speed.

Use stroke limit switch.

PLC + touch screen full automatic control

The wheel runs in the rail stably and smoothly, with low noise,extend the use life.

The reciprocator speed fully match the convey chain, running smoothly to assure the the coating thickness even.

The stroke control is done by stroke limit switch. Besides, also designing a mechanical stroke limit control to double assure

better control even if there is wrong with the switch control.

3

Vertical curing oven

Heat preservation

Oven wall:

Inner wall plate δ1.2mm galvanized plate + 50+80mm rock wool + 40mm heat insulation wool + outer wall δ1.0mm coating plate

Oven wall:

Inner wall plate δ1.2mm galvanized plate + 120mm rock wool + 40mm heat insulation wool + outer wall δ1.0mm coating plate

Heat insulation is better. Out wall temperature is low . The temperature difference between oven outside and indoor temperature is

less than 15℃.

Heating method

Direct heating

Indirect heating

Gas direct heating can save more 10% -20% energy than indirect heating system. And no smoke produce.Don’t need buy smoking

removing equipment.

Temperature measuring

In the oven ,there are 6 different area temperature measuring and temperature sensor which can automatically measure temperature.

6 different area temperature measuring ,no temperature curve graph .

4

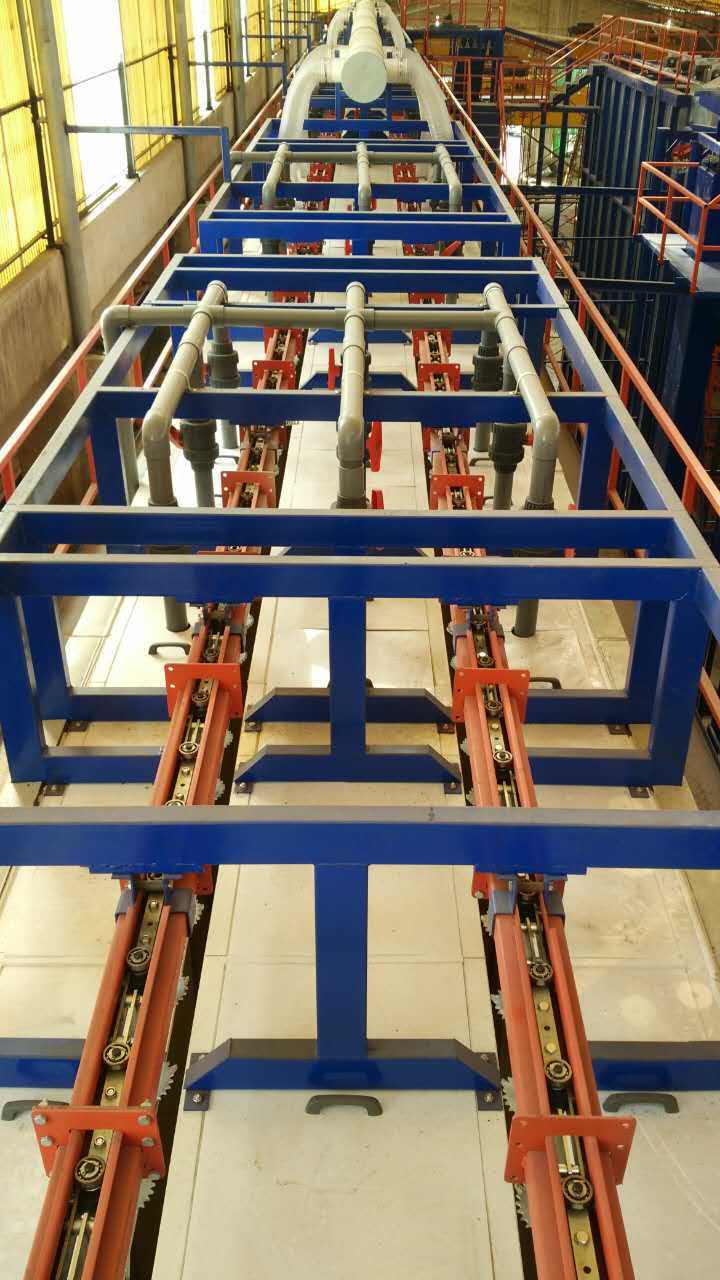

Convey chain

Brand

Chengde Guangda chain

Produced by themselves

The chain is produced and designed by famous company in China. Running is stable and smooth.life is longer and so on. But price

will be more expensive.

1、design data

A、coating material: aluminum profile

B、 process description

a、loading, pretreatment, water drying, powder coating, curing, unloading.

C、coating profiles:

1. maximum the size: 200mm×100mm×L6500mm

2. standard work piece weight: 3.5KG

3. standard work piece surface on average:1.2㎡/支

4. the standard speed of conveying chain : 1.2-1.5m/min(0.8m/min-3.5m/min adjustable)

2、 energy supply

A、liquified petroleum gas 、pipeline gas

B、water vapor

3、compress air

A、pressure:7.0bar

B、maximum quantity of steam:1.2g/nm3

C、Maximum quantity of oil:0.02ppm

D、:9.7m3/min

D、Maximum flow of compressed air:9.7m3/min

4、industry water

A、 pressure:3+0.2bar

B、 flow:5m3/h

5、deionized water rinse

A、electric conductivity:10us/cm

B、flow: 3m3/h

6、powder coating

A、characteristics of powder:LEL≥40g/Nm3

7、the space of hanging material:66mm、100mm、133mm、200mm

8、reference output:

A、standard speed of the coating chain:1.3m/min

Every hour spraying quantity: 1300mm/min÷100mm/piece×60min=780 pieces

Every hour spraying weight: 780 pieces×3.5kilogram/piece =2.73tons

monthly output:2.73 tons ×20 hours/day ×26/month =1419 tons/month

Our vertical line advantage brief

Equipment Name

What we use

What other factories use

Our advantage

1

pretreatment

Wall material

+PVC

Stainless steel+PVC anticorrossive system

Stainless steel

Stainless steel+PVC anticorrossive system has stronger ani ecrossion with longer life.

Waterfall equipment

Stable pressure water pump + duck mouth faucet

Basin

The water with chemical fall down more stably and smoothly and make profile cleaning better.

Water Pump

Horizontal fluoroplastics pump or Alloy pump

Alloy pump

fluoroplastics pump: outside is metal,inside is fluoroplastics , be suitable for -85~150℃ corrosive material, it is the most

advanced anti-corrosive in the world .It has longer life than alloy pump.

2

Powder coating booth

The third generation V shaped booth + PE double side recycling belt(automatic cleaning self)

The first generation V shaped booth +polythene film recycling belt

Or the second generation U shaped Booth+ PE recycling belt

Our third generation booth : no powder overflow,

Powder recycling can be done just by a vacuum pump.

The energy consumption is better than the first generation and second generation one. Morever ,it is more easily to clean and

shorten the cleaning time. Our PE belt can be recycling use and save cost from long term.

The first recycling system

Big cyclone

Big cyclone

Our recycling rate is more than 97%. Can save 1-2kg powder per ton profile basis on the common used powder

Filtering system

Filtering bag filtering system

Filtering bag filtering system

Reciprocator

The running rail use real lift rail.

The wheel use polyurethane.

Use digital frequency conversion to adjust speed.

Use stroke limit switch.

PLC + touch screen full automatic control

The wheel runs in the rail stably and smoothly, with low noise,extend the use life.

The reciprocator speed fully match the convey chain, running smoothly to assure the the coating thickness even.

The stroke control is done by stroke limit switch. Besides, also designing a mechanical stroke limit control to double assure

better control even if there is wrong with the switch control.

3

Vertical curing oven

Heat preservation

Oven wall:

Inner wall plate δ1.2mm galvanized plate + 50+80mm rock wool + 40mm heat insulation wool + outer wall δ1.0mm coating plate

Oven wall:

Inner wall plate δ1.2mm galvanized plate + 120mm rock wool + 40mm heat insulation wool + outer wall δ1.0mm coating plate

Heat insulation is better. Out wall temperature is low . The temperature difference between oven outside and indoor temperature is

less than 15℃.

Heating method

Direct heating

Indirect heating

Gas direct heating can save more 10% -20% energy than indirect heating system. And no smoke produce.Don’t need buy smoking

removing equipment.

Temperature measuring

In the oven ,there are 6 different area temperature measuring and temperature sensor which can automatically measure temperature.

6 different area temperature measuring ,no temperature curve graph .

4

Convey chain

Brand

Chengde Guangda chain

Produced by themselves

The chain is produced and designed by famous company in China. Running is stable and smooth.life is longer and so on. But price

will be more expensive.

Product Images

After-Sale Service

Hot Searches