- Product Details

- {{item.text}}

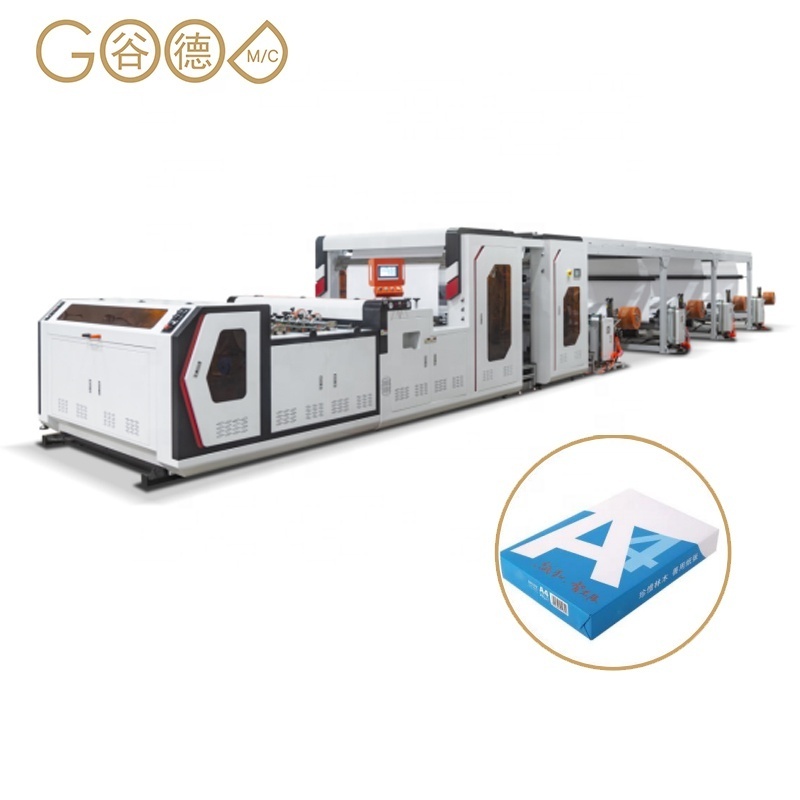

Quick Details

-

Brand Name:

-

GOOD

-

Voltage:

-

380V 3 PHASE

-

Power:

-

17KW

-

Dimension(L*W*H):

-

18000*2200*2000MM

-

Weight:

-

8600 kg

-

Certification:

-

ce

-

After-sales Service Provided:

-

Online support

-

Max Cutting Width:

-

1400

-

Max Roll Diameter:

-

1400mm

-

Min Cut Width:

-

50mm

-

Type:

-

paper cutting and packing machine

-

Speed:

-

10-180 stokes/min

-

Total Power:

-

17kw

-

Precision:

-

+-0.2mm

Quick Details

-

Production Capacity:

-

100 pcs/min

-

Product Type:

-

paper cutting machine

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

GOOD

-

Voltage:

-

380V 3 PHASE

-

Power:

-

17KW

-

Dimension(L*W*H):

-

18000*2200*2000MM

-

Weight:

-

8600 kg

-

Certification:

-

ce

-

After-sales Service Provided:

-

Online support

-

Max Cutting Width:

-

1400

-

Max Roll Diameter:

-

1400mm

-

Min Cut Width:

-

50mm

-

Type:

-

paper cutting and packing machine

-

Speed:

-

10-180 stokes/min

-

Total Power:

-

17kw

-

Precision:

-

+-0.2mm

Why Choose Us

Products Description

|

Model

|

HQJ1100A4

|

|

HQJ1400A4

|

|

||

|

Max Cutting Width

|

1100

|

|

1400

|

|

||

|

Max Roll Diameter

|

1400mm

|

|

1400mm

|

|

||

|

Min Cut Width

|

50mm

|

|

50mm

|

|

||

|

Speed

|

10-180 storkes/min

|

|

10-180 storkes/min

|

|

||

|

Precision

|

+- 0.2mm

|

|

+- 0.2mm

|

|

||

|

Total Power

|

15kw

|

|

17kw

|

|

||

|

Weight

|

8000kgs

|

|

8600kgs

|

|

||

|

dimension(Lx Wx H)

|

18000*1950*2000mm

|

|

18000*2200*2000mm

|

|

||

More Product

Details Images

Title goes here.

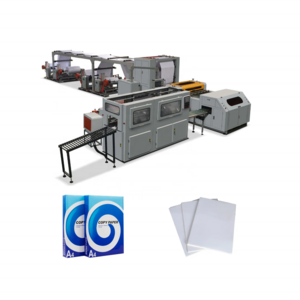

一、Application: this machine is suitable for automatic cutting of all kinds of office paper bloom photographic paper, also suitable for all kinds of PET, self-adhesive and all kinds of paper, plastic composite materials.

二、Performance and features:

1、This machine adopts servo motor fixed length cutting, adopts PLC program control system centralized control, aiming at the reel material in the market, through the program to cut it into different specifications one-time. At the same time through the conveyor belt, transported to the finishing table for automatic stacking, transmission part of the stainless steel baffle isolation, about the material will not cross, finishing flat. Simple operation, high degree of automation, relative to the traditional cutting process, saving labor.

2、The transmission system is controlled by mechanical cam, combined with pneumatic and photoelectric sensors, and the discharging system adopts cylinder expanding shaft automatic lifting device with large load The machine integrates light, electricity, gas, one, cutting precision, mechanical stability, low noise and other advantages.

3. The main motor adopts the advanced functions such as frequency conversion, automatic counting, alarm stopping, digital display of tension, etc. .

Hot Searches