- Product Details

- {{item.text}}

Quick Details

-

Power:

-

200W

-

Weight:

-

120 KG

-

Evaporation Surface Area:

-

0.25㎡

-

Column Diameter:

-

150mm (6 inch)

-

Feeding Flask Volume:

-

2L

-

Feed Rate:

-

2-10L/H

-

Throughput:

-

2-5L/H

-

Receiving Flask Volume:

-

5L

-

Motor Power:

-

200W

-

Stirring Mode:

-

'Magnetic Stirring

-

Rotating Speed:

-

'0-500RPM

-

Working Temperature:

-

Room Temp. to 250℃

Quick Details

-

Place of Origin:

-

Shanghai

-

Brand Name:

-

Valuen

-

Voltage:

-

220V

-

Power:

-

200W

-

Weight:

-

120 KG

-

Evaporation Surface Area:

-

0.25㎡

-

Column Diameter:

-

150mm (6 inch)

-

Feeding Flask Volume:

-

2L

-

Feed Rate:

-

2-10L/H

-

Throughput:

-

2-5L/H

-

Receiving Flask Volume:

-

5L

-

Motor Power:

-

200W

-

Stirring Mode:

-

'Magnetic Stirring

-

Rotating Speed:

-

'0-500RPM

-

Working Temperature:

-

Room Temp. to 250℃

Product Description

|

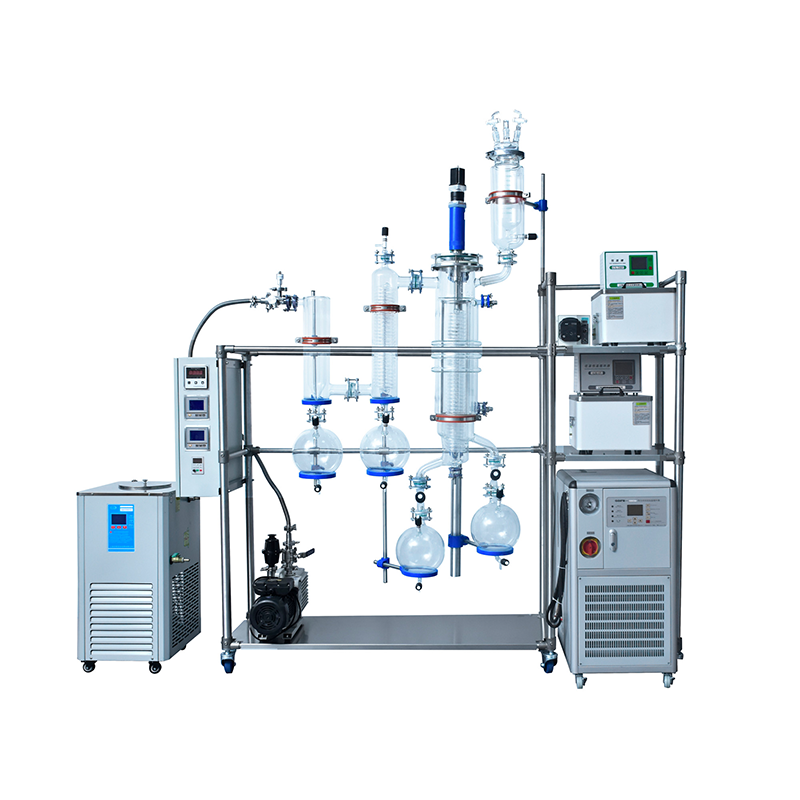

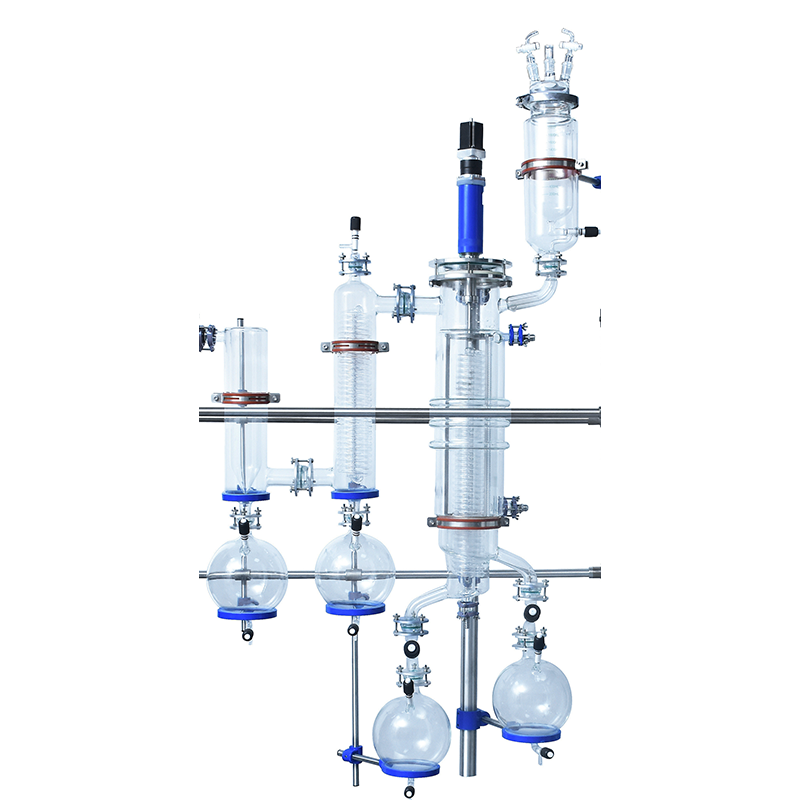

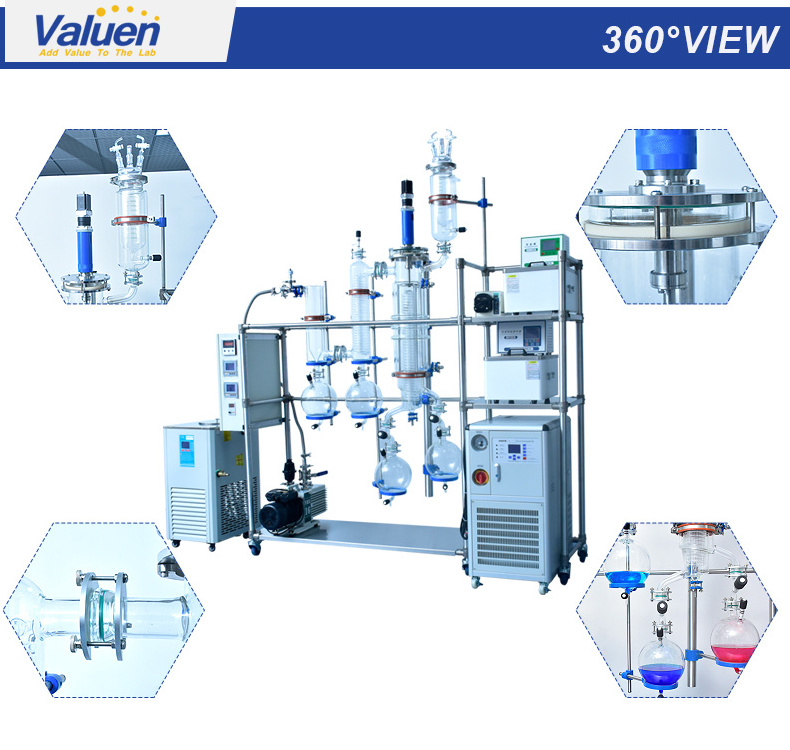

6inch Glass Wiped (Thin) Film (Molecular) Distillation System

Short Path Evaporation Technology Applied For Thermally Sensitive And High Boiling Points Compounds High Precision PTFE Scraper For Forming A Complete And Even Thin Film For Short Residence Time And High Distillation Rates Non-stop Running and Easy Operation of Main Distiller and All Utilities |

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

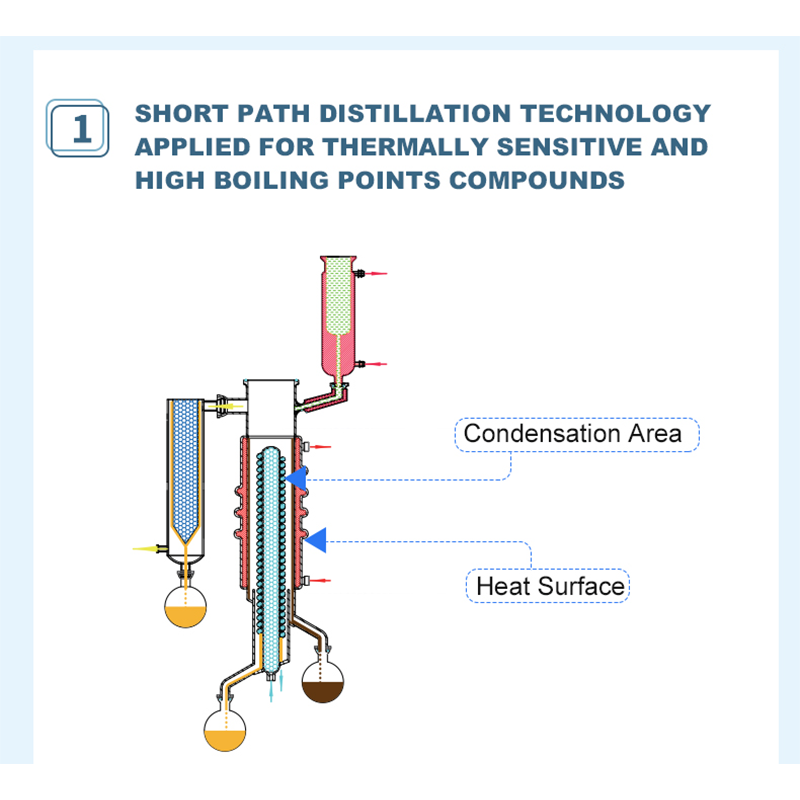

Work Principles Of Short Path Distillation

Short path distillation gets its name from the distance in which the vapor stream is condensed. In this case, the evaporator wall generates the vapors as the feed moves by gravity, while being agitated and distributed evenly into what is known as a thin film, down the evaporator wall. The vapor stream travels a "short path" directly to the condenser which is located within the evaporator chamber. Since the vapor stream is immediately condensed, the short path distillation process precludes the vapor from forming vapor pressure. The advantage is that the heating temperature can be considerably lower at reduced pressure than the boiling point of the liquid at standard pressure, and the distillate only has to travel a short distance before condensing. A short path ensures that little compound is lost on the sides of the apparatus. |

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

Model

|

VWF02G

|

VWF03G

|

VWF06G

|

||

|

Evaporation Surface Area

|

0.06㎡

|

0.1㎡

|

0.25㎡

|

||

|

Column Diamter

|

60mm (2.4inch)

|

80mm (3.2inch)

|

150mm (6 inch)

|

||

|

Feeding Flask Volume

|

1L

|

1.5L

|

2L

|

||

|

Feed Rate

|

0.5-3.5L/H

|

1-5L/H

|

2-10L/h

|

||

|

Feeding Mode

|

Manual Feeding via feeding valve or Auto Feeding by input pump

|

|

|

||

|

Throughput

|

0.5-1.75L/H

|

1-2.5L/H

|

2-5L/H

|

||

|

Distillate Receiving Flask Volume

|

1L

|

1L

|

5L

|

||

|

Residue Receiving Flask Volume

|

1L

|

1L

|

5L

|

||

|

Discharging Mode

|

Manual Discharging or Auto Discharging by output pumps

|

|

|

||

|

Cold Trap & Condensers

|

3 Modules for Options: I: 1 Cold Trap; II: 1 Coils Condenser and 1 Cold Trap; III: 2 Coils Condensers

|

|

|

||

|

Control Cabinet

|

Rotating speed controller, Vacuum meter, Temperature controller of heating tape (Optional: Integrate all utilities control on

control panel ) |

|

|

||

|

Stirring Mode

|

Magnetic Stirring

|

|

|

||

|

Rotating Speed

|

0-500RPM

|

|

|

||

|

Wiper Style

|

PTFE blades or rollers

|

|

|

||

|

Motor Power

|

120W

|

|

200W

|

||

|

Power Supply

|

220V, 50/60Hz, Single Phase

|

|

|

||

|

Utilities (Optional)

|

Heaters for feeding tank, Main Column; Chillers for Internal and External Coils Condensers Vacuum Pump ( 1 or 2 stage)

|

|

|

||

|

Sealing

|

Main Sealing: magnetic coupling sealing; Connection Sealing: Viton O rings &Ball Clamps

|

|

|

||

|

Working Temperature

|

Room Temp. to 250℃

|

|

|

||

|

We Provide Turnkey Set

Glass Wiped (Molecular) Distillation Equipment Heaters Chillers Vacuum Pump |

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

Hot Searches