- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Sichuan, China

-

Brand Name:

-

Topcoat Solution

-

Model Number:

-

B105QL011B

-

Width:

-

50cm

-

Place of origin:

-

China

-

Pattern:

-

Water Transfer Print Foil Water Transfer Printing Film Hydrographics

-

Shipping:

-

FedEx/DHL/UPS/EMS/TNT

-

Product name:

-

hydrographic water transfer film hydrodipping hydr

-

Advantage:

-

hugh stock fastest shipping

-

Key words:

-

Water Transfer Printing Film Hydrographics No :K009F1145B

-

MOQ:

-

10sqms for a single pattern

-

Customize:

-

Available

Quick Details

-

Material:

-

Japan PVA film

-

Application:

-

hydrographic film for car car parts motocycle car wheels

-

Type:

-

Water Transfer

-

Place of Origin:

-

Sichuan, China

-

Brand Name:

-

Topcoat Solution

-

Model Number:

-

B105QL011B

-

Width:

-

50cm

-

Place of origin:

-

China

-

Pattern:

-

Water Transfer Print Foil Water Transfer Printing Film Hydrographics

-

Shipping:

-

FedEx/DHL/UPS/EMS/TNT

-

Product name:

-

hydrographic water transfer film hydrodipping hydr

-

Advantage:

-

hugh stock fastest shipping

-

Key words:

-

Water Transfer Printing Film Hydrographics No :K009F1145B

-

MOQ:

-

10sqms for a single pattern

-

Customize:

-

Available

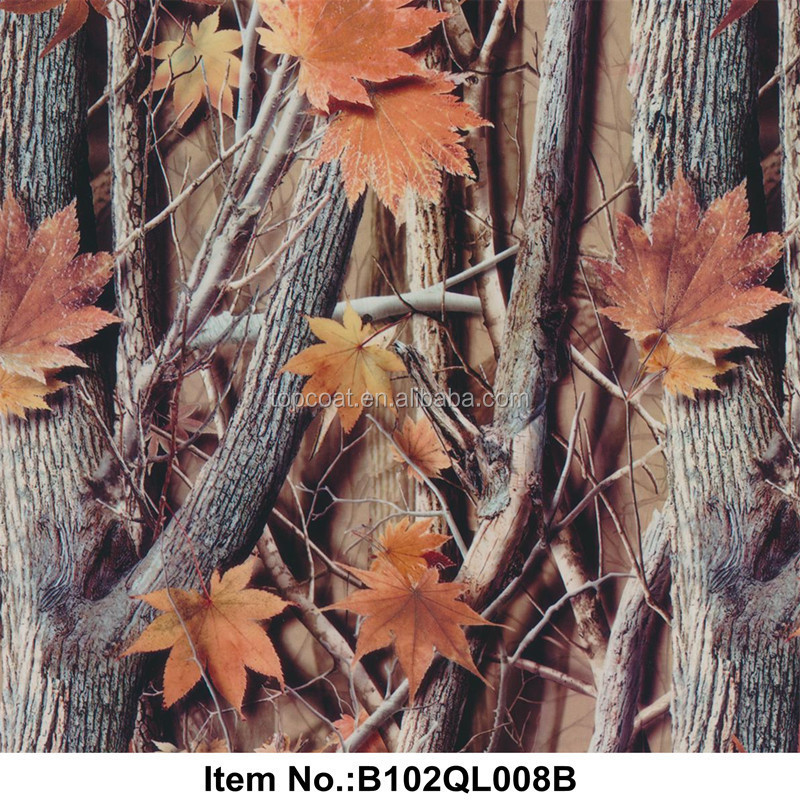

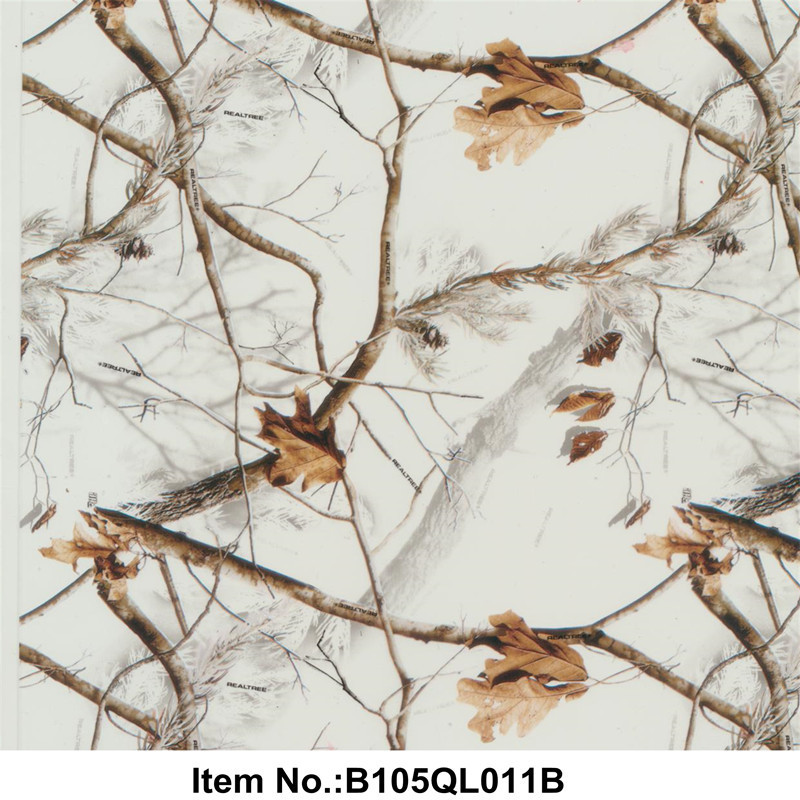

TCS HYDROGRAPHIC FILM WATER TRANSFER HYDRODIPPING HYDRO DIP REAL TREE CAMO for Car No :B105QL011B

| Material | PVA Film | Width | 50cm |

| MOQ | 10 square meters | Unit Price | 1.8-2.4USD |

| Shipping | FedEx/DHL/TNT/EMS | Delivery | 3-5Days |

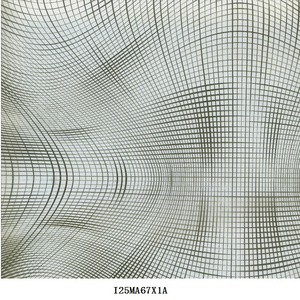

| Our Patterns |

Carbon fibers ,Skull ,Cartoon ,Illusion ,Sticker Bomb ,Marble ,Camo tree ,Camo flage,wood grain ,laser film and Etc. We also can offer you customized patterns . |

||

Contact us for full catalogue . (Pls see the contact information at the end of this page )

Product Picture

Storage :

•The film should be packed in a plastic bag.

•Lay film face down on flat surface with a flat item such as a book on top for weight to keep

paper from curling.

•Film Storage: 18-25°C (64-77°F)

• Optimum Temperature: 21.5°C ( 70.7°F)

•Humidity: 45-65%

•Do not open until ready to use.

Expiration Date(before transfer): 2 years

Dipping Process:

Step 1

Dip a little water on your finger and touch one angle of the film, make the sticky-hand side

down to the water and lie flat.

Remember any water on the face of the film is not allowed

.

Wait till the film become flat.

Step 2

Spray activator on the film evenly. Wait about 30 seconds or more (If in winter that time

would be as long as 1 minutes)to get an effect of film solvent. This step is very important.

The film needs enough time to be activated.

Step 3

Tilt the workpiece at 45 degree angle to the water tank . Keep this degree angle then dip it

in the Tank. During this period, don’t get it out of the water tank. Finally, wash it constantly

until the residue is cleaned away.

Step 4

Drying the workpiece and then spray the top-coat to protect the finished workpiece.