The vertical crusher is a professional organic fertilizer crusher that our company's engineering researchers have integrated with domestic and foreign advanced crushing technology and repeatedly researched, improved, and carefully manufactured with many years of production experience. The vertical crusher completely solves the problem of crushing organic matter with high water content. The successful development of the vertical grinder plays a key role in shortening the process of producing bio-organic fertilizer and compost, reducing equipment investment, and saving operating costs.

- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

10

-

Range of Spindle Speed(r.p.m):

-

10 - 15 r.p.m

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

jiuling

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

1800*1200*2500

-

Weight (KG):

-

1120 KG

-

Product name:

-

Crusher machine

-

Usage:

-

Animal Poultry crusher

-

Name:

-

Animal waste crusher machine

-

Raw material:

-

Animal Manure

-

After-sales Service Provided:

-

24 Hours

-

Function:

-

Multifunctional

-

Capacity:

-

1t-20t/h

-

Advantage:

-

High Capacity

-

Port:

-

Qingdao /lianyungang

Quick Details

-

Output (kg/h):

-

3000 - 20000 kg/h

-

Feeding Size (mm):

-

10 - 20 mm

-

Output Size (mesh):

-

1 - 5 mesh

-

Power (kW):

-

10

-

Range of Spindle Speed(r.p.m):

-

10 - 15 r.p.m

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

jiuling

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

1800*1200*2500

-

Weight (KG):

-

1120 KG

-

Product name:

-

Crusher machine

-

Usage:

-

Animal Poultry crusher

-

Name:

-

Animal waste crusher machine

-

Raw material:

-

Animal Manure

-

After-sales Service Provided:

-

24 Hours

-

Function:

-

Multifunctional

-

Capacity:

-

1t-20t/h

-

Advantage:

-

High Capacity

-

Port:

-

Qingdao /lianyungang

Products Description

Vertical Crusher Description

Product Advantages

1. design for high moisture material,not easy to block,and material discharging is smooth.

2. service life longer, because of High strength and wear-resistant alloy steel.

3. high crushing efficiency.

Product Paramenters

|

Model

|

Capacity(t/h)

|

Power(kw)

|

Size(mm)

|

Weight(kg)

|

Inlet size(mm)

|

|

JLLF-600

|

3-5

|

22

|

1300*750*1900

|

680

|

800*400

|

|

JLLF-800

|

5-8

|

30

|

1800*1020*2100

|

850

|

1200*400

|

|

JLLF-1000

|

8-15

|

37

|

1800*1200*2500

|

1120

|

1300*450

|

|

JLLF-1200

|

15-20

|

55

|

2300*1500*3400

|

1560

|

1500*800

|

Product Application

Suitable for the range of applications

Agricultural Straw

Chicken Manure

Sheep Manure

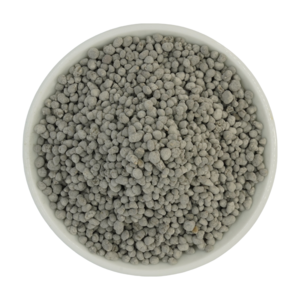

Bentonite

Related production line display

Organic Fertilizer Production Line

Processing commercial organic fertilizer requires two steps: the preliminary fermentation and processing part and the deep processing and granulation part. Supporting equipment requires fermentation machine,organic fertilizer crusher,screen machine,mixer,organic fertilizer granulator, rotary dryer,rotary cooler, coating machine, packaging machine, conveyor and other auxiliary equipment.

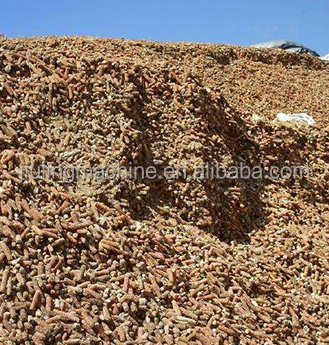

Disply the finished pellets

Customer visit factory

Sincerely welcome customers from all over the world to visit our factory

!

1.20GP or 40HQ container by sea or train , as well as wooden package

2.Shippment : 10-15 working days once advanced payment.

2.Shippment : 10-15 working days once advanced payment.

Our Services

Pre-sale

1.Our sales manager will recommend the right machines according to your your raw materials.

2.

We can provide you with free site design guidance and 3d equipment production line drawings.

3.

To provide you with a detailed description of each equipment and video to see our equipment work site.

4.We can make granulation experiment according to your raw materials

.

On sale

1.During the production of the equipment, we will feed back the production progress to you

2.We support customer on-site inspection, video inspection, third party inspection, factory inspection agency inspection

3.We offer you a free test service before the machine leaves the factory

After-sales

1. We have a professional after-sales team and experienced engineers will guide you how to install the equipment.

2.We support free spare parts for you within one year of purchase.

3.We will provide a two-year warranty on important parts of the equipment

FAQ

1. Can I visit your factory and clients' workshop?

Yes, welcome to visit our factory anytime, we can also arrange your visit in our China clients' workshop.

2: Where your products have been exported before?

Our products have been sold to South Asia, Africa, South America, middle East and so on.

3.What is your guarantee time and aftersale service?

Our guarantee time is 12 months for all kinds of products.

Any problem in operation or others about machines, we will give solution in 12-24hours.

4.What is your payment term?

We can accept T/T, L/C Paypal is available.

5. What is your delivery time?

The machine leadtime is 7 working days in standard specification, 10-15 working days if customized.

Please tell your questions, Jiuling factory team are happy to serve&ready to be your business partner! If you want to know more details, please contact us ! Your satisfaction is our greatest pursuit.

Hot Searches