- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

4.6*2.1*2.1m

-

Voltage:

-

Customize

-

Power:

-

1.5KW

-

Weight (KG):

-

3500

-

Product name:

-

carbonization furnace stove

-

Capacity:

-

7000kg/24h

-

Usage:

-

charcoal making furnace

-

Keywords:

-

carbon carbonization furnace

-

Advantage:

-

Low Consumption High Efficiency

-

Instalation:

-

Engineer Guide

-

Carbonization time:

-

6-8 hours

-

Fuel:

-

coal stove

-

Volume:

-

10m³

-

Color:

-

Customer's Request

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Superb

-

Effective Volume:

-

3CBM

-

Dimension(L*W*H):

-

4.6*2.1*2.1m

-

Voltage:

-

Customize

-

Power:

-

1.5KW

-

Weight (KG):

-

3500

-

Product name:

-

carbonization furnace stove

-

Capacity:

-

7000kg/24h

-

Usage:

-

charcoal making furnace

-

Keywords:

-

carbon carbonization furnace

-

Advantage:

-

Low Consumption High Efficiency

-

Instalation:

-

Engineer Guide

-

Carbonization time:

-

6-8 hours

-

Fuel:

-

coal stove

-

Volume:

-

10m³

-

Color:

-

Customer's Request

Product Description

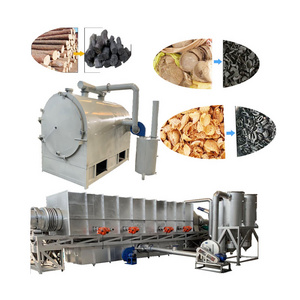

saw dust carbonization furnace charcoal making machine from rice husk

Carbon carbonization furnace

is a kind of new air flow type carbonization stove, can also be called as charcoal carbonization stove. It is used to make charcoal from wood and all kinds of biomass. It adopts new advanced hot air carbonizing technology, greatly improves the carbonization rate to 99%, compared with the carbonization rate 80% of traditional carbonization stove! Its charcoal making time is short .This kind stove is safe and easy to operate, the charcoal made from the carbonizing furnace can be the material of activated carbon. thus it is very famous among many industries like charcoal making industry and boiler industry.

Application

Widely used for carbonizing log, wood, jute stick and other long rod-type biomass.

Carbonized products

Technical Parameter

|

Model

|

STHL120

|

STHL170A

|

STHL170B

|

STHL190

|

|||

|

Capacity

|

2000kg/24h

|

4000kg/24h

|

7000kg/24h

|

10500kg/24h

|

|||

|

Dimension

|

2.86*1.6*2.1m

|

2.85*2.1*2.1m

|

4.6*2.1*2.1m

|

5.5*2.2*2.2m

|

|||

|

Weight

|

1.68t

|

3t

|

3.5t

|

6.8t

|

|||

|

Inner Pot Diameter

|

1.2m

|

1.7m

|

1.7m

|

1.9m

|

|||

|

Inner Pot Length

|

2.6m

|

2.2m

|

4.4m

|

5.3m

|

|||

|

Volume

|

3m³

|

5m³

|

10m³

|

15m³

|

|||

|

Carbonization

|

6-8 hours

|

|

|

|

|||

Main Process

Advantages

Advantages of

saw dust carbonisation furnace charcoal making machine from rice husk

:

a. No pollution:

there are two reasons : the frog and the gas flow will be recycle from the smoke recycle device and use for heating the kiln again. We install a special device that can use the liquid gas as the energy to heating the carbonization kiln, and it will not produce any smoke.

b. Carbonize time more shorter:

This type have three inner stove, when one inner stove finished (6- 8hours ) , use the hoist tools lift the inner stove out let it cooled naturally, at the same time, lift the other one in , 3 inner stove can work continuously. 24 hours can carbonizing 3-4 inner stove.

c. Easy operate:

One people can control 2-3set, but need the crane for help; When one inner stove have been finished carbonization, use the hoisting tools hoist the inner stove from the outer stove, then let the inner stove natural cooling, at the same time, put another inner stove into the outer stove, which will save a lot of cooling time, so the productivity effect increase a lot.

Packing & Delivery

1.Packaging in wooden boxes;

2.Delivery the machine by 20-foot container/40-foot container;

3.Once the product is sold, if it is not a product quality problem, it cannot be returned or refunded.

Hot Searches