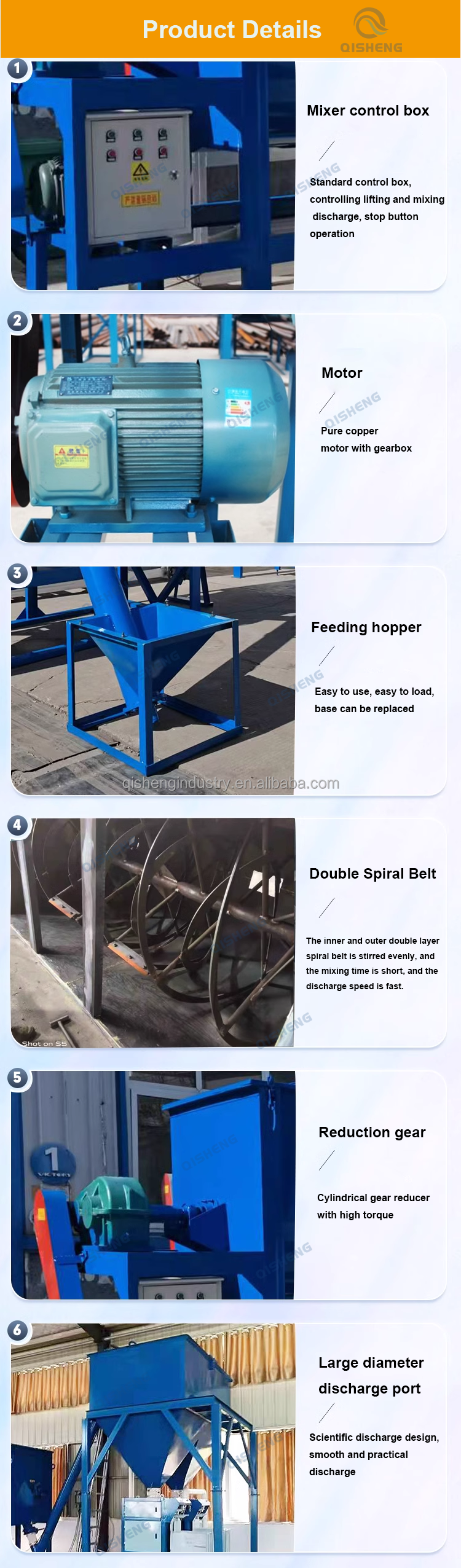

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

QISHENG

-

Voltage:

-

380V 3 phases or customized voltage

-

Power:

-

22

-

Dimension(L*W*H):

-

referring to drawing

-

Weight:

-

3800 kg

-

Features:

-

powder, granule mixing and package

-

Product name:

-

horizontal ribbon epoxy putty mixture machine

-

Batching and weighting:

-

Manual+simple Automatic

-

Productivity:

-

1-6t/h

-

Mixer Type:

-

Horizontal Spiral Ribbon Mixer

-

Max Discharging Capacity::

-

2000L

-

Man power:

-

2-3 person

-

Mixing time:

-

5-8 Mintues

Quick Details

-

Marketing Type:

-

New Product 2023

-

Application:

-

putty powder, dry powder mortar, etc

-

Place of Origin:

-

China

-

Brand Name:

-

QISHENG

-

Voltage:

-

380V 3 phases or customized voltage

-

Power:

-

22

-

Dimension(L*W*H):

-

referring to drawing

-

Weight:

-

3800 kg

-

Features:

-

powder, granule mixing and package

-

Product name:

-

horizontal ribbon epoxy putty mixture machine

-

Batching and weighting:

-

Manual+simple Automatic

-

Productivity:

-

1-6t/h

-

Mixer Type:

-

Horizontal Spiral Ribbon Mixer

-

Max Discharging Capacity::

-

2000L

-

Man power:

-

2-3 person

-

Mixing time:

-

5-8 Mintues

3 ton dry mortar industrial mixer best wall putty manufacturing machine horizontal ribbon epoxy putty mixture machine

Product Description

Introduction

QISHENG dry powder mortar production line is a new type of high-efficiency mixing equipment, which is widely used in putty paste,real stone paint, dry powder, putty, medicine, food, chemicals, feed, ceramics, refractories, etc. industries.

This equipment is mainly suitable for the production of dry powder coatings such as putty powder, dry powder mortar, tile adhesive, pointing agent, and quick adhesive powder.

Features:

Dry mortar production machinery is mainly composed of dry mortar mixer, feed screw conveyor, three ribbon mixing machine, secondary hoist, a storage hopper and automatic packing machine, etc..

The main mechanism of the horizontal ribbon mixer is the shearing effect of the ribbon. Through the high-speed rotation of the mixing shaft, the horizontal multi-spiral belt mixer enables the inner and outer spiral belts to turn the material in a larger range. Through the above-mentioned movement, the materials are quickly and uniformly mixed in a short time.

This system is an efficiency production system after multiple times improvement on the basis of multiple ribbons dry mortar mixer. Mixed product will be into a storage bin through second lift machine. Then worker can carry out filing operation and not affect the next production. Matching an accurate packing machine can greatly improve production efficiency.

Technical data of dry powder mortar production line

|

Model

|

Out put

|

Occupied area

|

Equipment Height

|

Manpower

|

Batching and packaging

|

||||

|

QS-1000

|

1-3t/h

|

20m2

|

3-4m

|

2-3 Person

|

Manual batching

Automatic packaging

|

||||

|

QS-2000

|

4-5t/h

|

20m2

|

3-5m

|

2-3 Person

|

Manual batching

Automatic packaging |

||||

|

QS-3000

|

6-8t/h

|

50-60m2

|

6-8m

|

3-4 Person

|

Manual batching

Automatic packaging |

||||

|

QS-5000

|

8-30t/h

|

60-100m2

|

8-13m

|

3-4 Person

|

Manual batching

Automatic packaging |

||||

|

Remarks

|

|

Above data is just for reference.Machine is customized,different materials moisture ,density,capacity request ,the parameter may has Subtle gap difference ,Please refer to the actual situation.

|

|

|

|

||||

Recommend Products

Packing & Delivery

Packing: Nude or plywood case or as request

Delivery Date: 7-20 days after confirm the down payment according to order quantity and buyer's request.

Shipping Method: By sea

Shipping Port: Qingdao, China

Why Choose Us

♦Pre-sales:

1 Perfect 7*24hours inquiry and professional consulting service

2.Visit our factory anytime

♦Sale:

1. Update the production schedule in time

2. Quality supervision

3. Product acceptance

4. Shipping on time

♦After-sales:

1. Guarantee:1 year ,during this period we will offer free spare parts if they are broken.

2. Training how to install and use machine

3. Engineers available to service overseas

4. Skill support during the whole using life

Hot Searches