The cutting unit adopts a general file shear type cutting mouth, which is flat, free of collapse angle and burr,

beautiful appearance and no waste

|

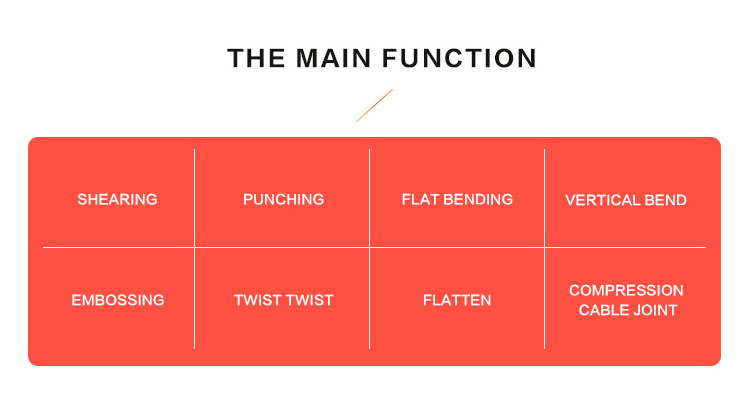

Function

|

ITEM

|

MX-303D

|

MX-303S

|

MX-503S

|

|

Punching

|

Max.strength (kn)

|

300

|

300

|

500

|

|

|

Diameter range (mm)

|

φ4.3~φ25

|

φ4.3~φ25

|

φ4.3~φ34

|

|

|

Max.thickness (mm)

|

12

|

16

|

16

|

|

|

Max.width (mm)

|

150

|

150

|

250

|

|

Shearing

|

Max.shearing thickness (mm)

|

12

|

12

|

16

|

|

|

Max.shearing width (mm)

|

150

|

150

|

250

|

|

Honrizental bending

|

Max.strength (mm)

|

300

|

300

|

500

|

|

|

Max.width (mm)

|

150

|

150

|

250

|

|

|

Max.thickness (mm)

|

12

|

12

|

16

|

|

Vertical bending

|

Max.width (mm)

|

100

|

100

|

120

|

|

|

Min.angle (degree)

|

90°

|

90°

|

90°

|

|

Dimension (mm)

|

( mm )

|

1500×1300×1200

|

1500×1300×1200

|

1800×1500×1300

|

|

Main motor power (Kw)

|

( kw )

|

1×4kw

|

3×4kw

|

3×5.5kw

|

|

Weight (kg)

|

( kg )

|

1050kg

|

1200kg

|

1750kg

|