- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

WONDERY

-

Voltage:

-

380V/220V

-

Power:

-

7KW

-

Dimension(L*W*H):

-

customized

-

Weight (KG):

-

7000

-

Name:

-

Aluminum ingot casting machine

-

Weight of each ingot:

-

6.0Kg

-

Production capacity:

-

5-7ton/hour

-

Total power:

-

7KW

-

Demoulding type:

-

pneumatic hammer and patented technology

-

Cooling type:

-

spray water cooling

-

Ingot mould:

-

cast iron with Japnese Standard

-

Transmission chain plate:

-

40Mn, 6mm

-

Transmission chain pitch:

-

6 inch

-

Consumption of cooling water:

-

10kg/Ton of aluminum

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Machine Type:

-

automatic

-

Marketing Type:

-

New Product 2022

-

Brand Name:

-

WONDERY

-

Voltage:

-

380V/220V

-

Power:

-

7KW

-

Dimension(L*W*H):

-

customized

-

Weight (KG):

-

7000

-

Name:

-

Aluminum ingot casting machine

-

Weight of each ingot:

-

6.0Kg

-

Production capacity:

-

5-7ton/hour

-

Total power:

-

7KW

-

Demoulding type:

-

pneumatic hammer and patented technology

-

Cooling type:

-

spray water cooling

-

Ingot mould:

-

cast iron with Japnese Standard

-

Transmission chain plate:

-

40Mn, 6mm

-

Transmission chain pitch:

-

6 inch

-

Consumption of cooling water:

-

10kg/Ton of aluminum

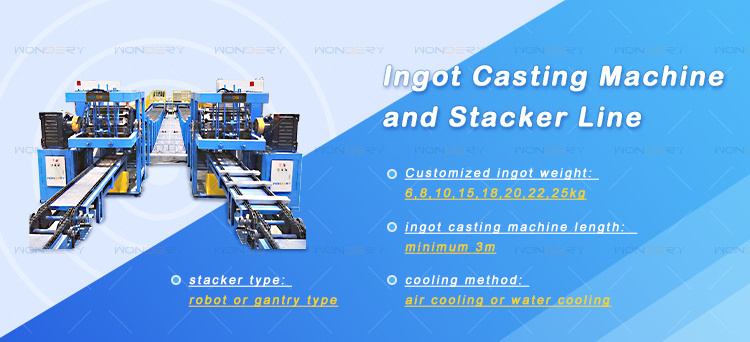

Automatic Aluminum Alloy Copper Ingot Casting Machine Production Line

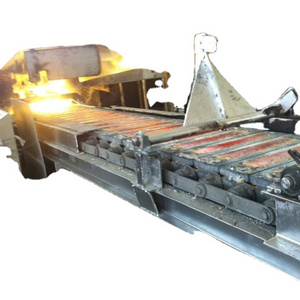

The ingot casting machine is used for fully automatic control production of ADC series grade 5.0-6.0 kg cast aluminum alloy ingots. The casting machine can meet the requirement of continuous production 24 hours a day, and the production process requirements of casting aluminum ingots and automatic stacking.

Product Features

1. The casting machine adopts linear cycle mode. The power drive part adopts the cycloidal pinwheel reducer, and frequency conversion speed regulation control. The driving power only needs 4.0KW which is more energy-saving and the operation is stable. The instrument directly shows the rotational speed of the casting machine every minute. The demoulding adopts universal hoop (patented product) and pneumatic hammer, and the demoulding rate reaches more than 99%.

2. The ingot casting machine has the advantages of automatic distribution of molten aluminium, frequency conversion speed regulation, high production efficiency, uniform ingot weight, high automation, low labor intensity, easy operation and simple maintenance.

2. The ingot casting machine has the advantages of automatic distribution of molten aluminium, frequency conversion speed regulation, high production efficiency, uniform ingot weight, high automation, low labor intensity, easy operation and simple maintenance.

3. The ingot casting machine is manufactured in accordance with the current national standards.

4. The whole system is safe and reliable with low operation cost, does not produce a large amount of steam, and has little environmental pollution. Because of the use of bottom water cooling, the quality of the product has been greatly improved, and the operation is convenient.

Wuxi Wondery Industry Equipment Co., Ltd

is a professional supplier of industrial furnaces. Currently the company mainly supplies the industrial furnaces for heat treatment industry, motor industry, fastener industry, die casting industry, gravity casting industry, steel wire manufacturing industry, etc. Our main products are: aluminum melting furnace, copper melting furnace, zinc melting furnace, crucible melting furnace, rotary melting furnace, melting tower, reverberatory melting furnace, ladle preheater, lader baker, ingot molds,heat treatment furnace, pit type carburizing furnace, pit type nitriding furnace, box type resistance furnace, bogie hearth furnace, salt bath furnace, mesh belt furnace, etc. Established in year 2008, the company has gained rich experiences in development and design, quality control, and after-sales service. The company aims to serve every customer with quality products and excellent service. The company provides thoughtful services like technical consultation, installation and test-running, technical training, and maintenance. Our company is also able to design non-standard products as per customers' requests. We have exported our machines and equipment to the following countries and areas: Taiwan (CHINA), Vietnam, Thailand, Pakistan, India, Venezuela, Bolivia, Mexico, Argentina, Columbia, Australia, USA, Kenya, Ethiopia, Qatar, Egypt, etc. We are capable of providing thoughtful solutions for every individual customer based on their specific requirements, making sure that every potential customer is satisfied with our work.

1. What is the power supply of the industrial furnace?

The power supply of industrial furnace is to be decided by the customer's side. We are able to adjust the power supply (volt, and phase) through a transformer or of the customer's voltage directly so that the industrial furnace is ready for use at the end user's site.

2. What information should the customer provide to get an accurate quotation from us?

The customer should provide the related technical requirements, drawings, pictures, industrial voltage, planned output, etc.

3. What is the payment term?

The payment term is 40% down payment, and 60% before delivery (T/T mode).

4. What is the delivery time?

The delivery time of the machine is 15-30 days after receipt of down payment.

Hot Searches