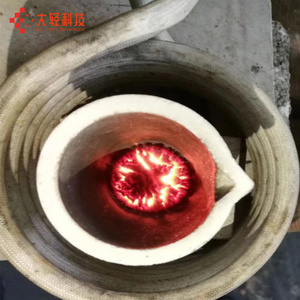

It is mainly used in smelting steel, iron, copper, aluminum and alloy,etc. It has the characteristics of high melting efficiency, good electricity saving effect, uniform metal composition, less burning loss, fast temperature rise, easy temperature control and so on.Suitable for all kinds of metal smelting occasions.

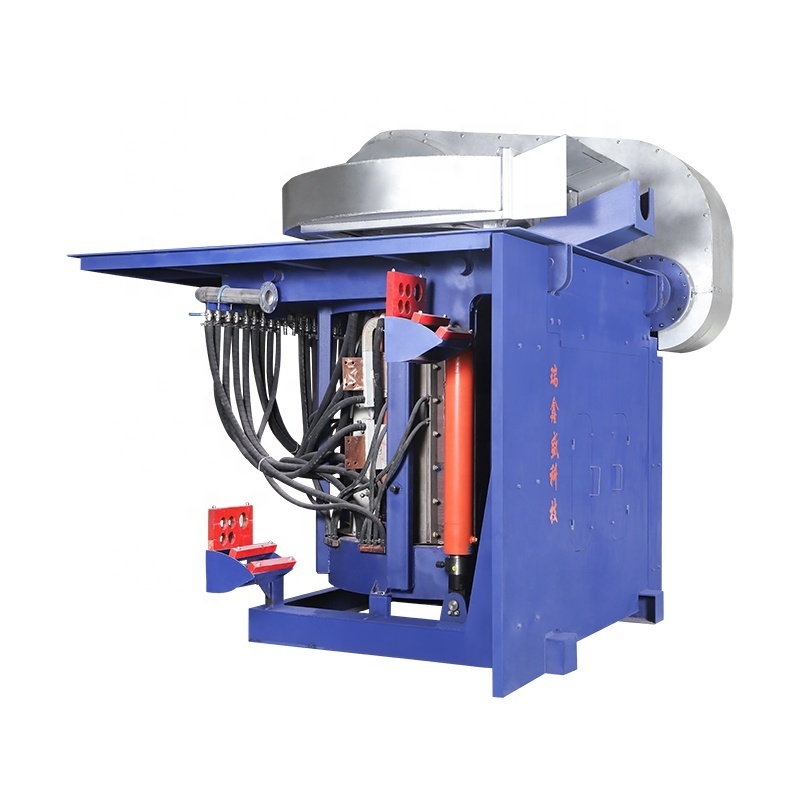

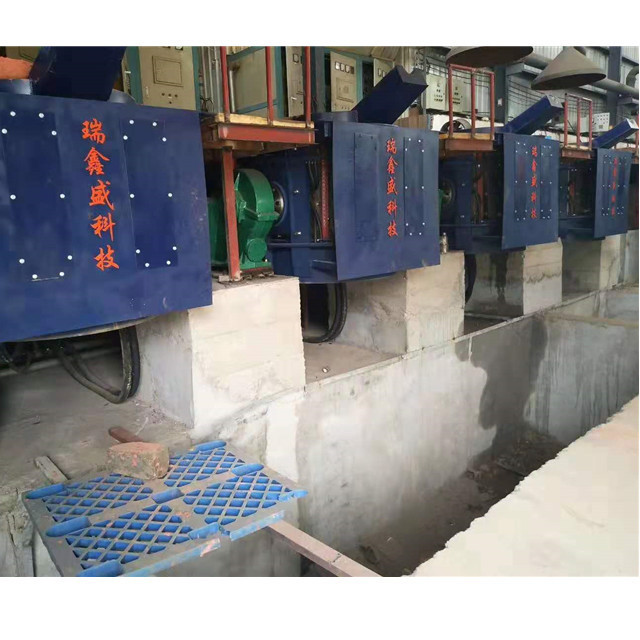

Adopting hydraulic tilting device.The furnace is welded with high quality steel structure, which is more safe, firm and durable;The sensor is enclosed by a magnetic yoke,cover area more than 65%.Therefore, less magnetic flux leakage, high efficiency, save nearly 5% energy consumption than aluminum shell furnace.Equipped with anti-leakage alarm device, can predict in advance to through the furnace, so as to achieve the purpose of safe production.Meanwhile,it can be equipped with the furnace lining ejector device.

Adopting hydraulic tilting device.The furnace is welded with high quality steel structure, which is more safe, firm and durable;The sensor is enclosed by a magnetic yoke,cover area more than 65%.Therefore, less magnetic flux leakage, high efficiency, save nearly 5% energy consumption than aluminum shell furnace.Equipped with anti-leakage alarm device, can predict in advance to through the furnace, so as to achieve the purpose of safe production.Meanwhile,it can be equipped with the furnace lining ejector device.