Fresh milk collected from the dairy farm needs to be stored in the refrigeration tank at low temperature. In order to ensure the

rigor of the production line, it needs to be weighed and preliminarily filtered.

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

2.2kw - 37kw

-

Weight:

-

550 KG

-

Dimension(L*W*H):

-

Customized

-

Processing:

-

Mixing + Pasteurizing+Freezing+Homogenizing +To

-

Raw material:

-

Fresh Liquid Milk

-

Keywords:

-

Yogurt Machine

-

Control type:

-

Fully Automatic

-

Application:

-

Food

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

WS

-

Voltage:

-

200V, 220V, 230V, 380V, 400V

-

Power:

-

2.2kw - 37kw

-

Weight:

-

550 KG

-

Dimension(L*W*H):

-

Customized

-

Processing:

-

Mixing + Pasteurizing+Freezing+Homogenizing +To

-

Raw material:

-

Fresh Liquid Milk

-

Keywords:

-

Yogurt Machine

-

Control type:

-

Fully Automatic

-

Application:

-

Food

We Have Our Own Independent Manufacturing Plant In Shanghai, China, Specializing In The Design, Development, Production And Sales Of Dairy, Juice And Beverage Lines, Etc. We Have More Than 25 Years Experience In The Industry, So You Can Contact Us And We Can Offer You The Best Factory Price.

lf You Have Any Requests Please Contact Us Through This Link !!!

Product Parameter

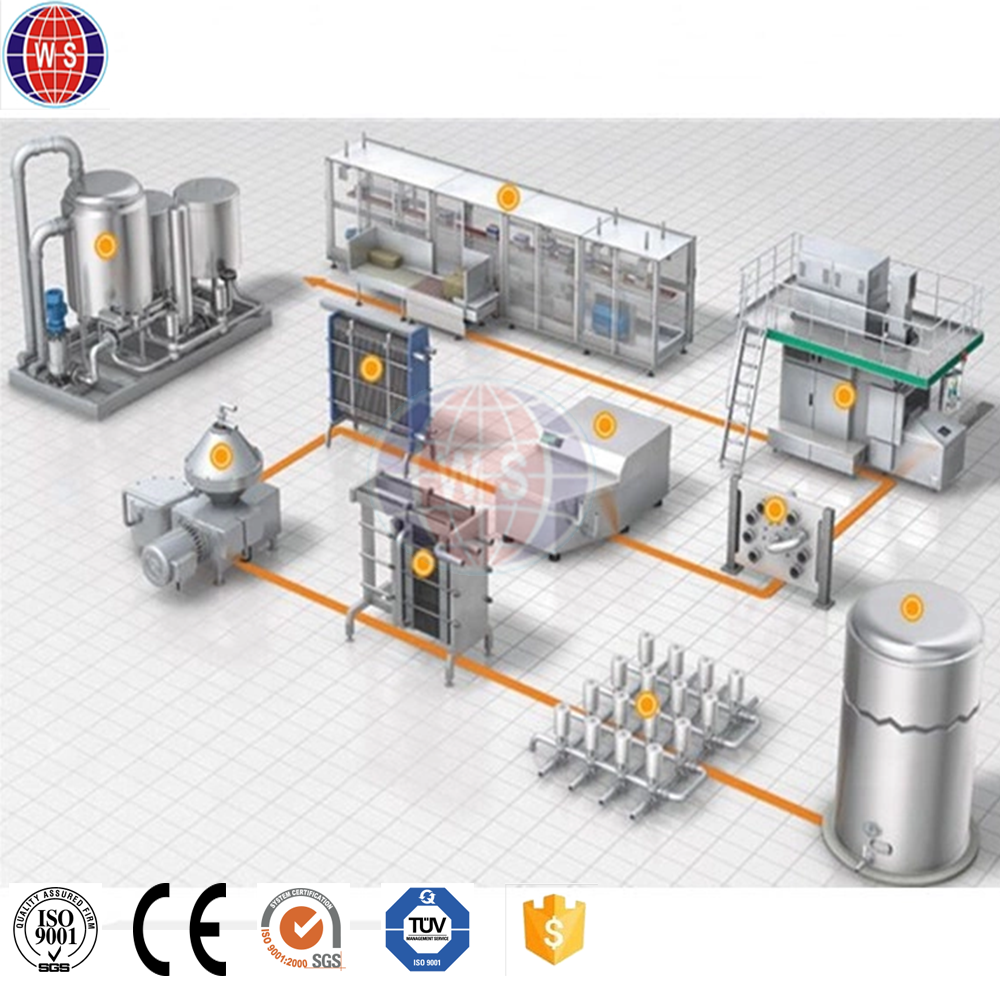

Production line introduction:

After the raw milk is pretreated and cooled to the inoculation temperature, the starter is continuously pumped into the fermentation tank. After the tank is full, start stirring for a few minutes to ensure that the starter is evenly dispersed. The fermentor is insulated to maintain a constant temperature throughout the incubation period. In order to check the acidity development in the tank, a pH meter can be installed on the tank. The culture time of stirred yoghurt was 2.5-3hr, 42-43 ℃, and the ordinary starter was used (inoculation amount was 2.5-3%). In order to obtain the best product, when the pH value reaches the ideal value, the bacterial fermentation must be stopped, and the temperature of the product should be cooled from 42-43 ℃ to 15-22 ℃ within 30 minutes. At the same time, in order to ensure the ideal viscosity of the finished product, the mechanical treatment of the clot must be gentle. Cooling is carried out in the plate heat exchanger with special plates, which can ensure that the product is not subject to strong mechanical disturbance. After cooling to 15-22 ℃, the yogurt is ready for packaging. Fruits and spices can be added during the transportation of yoghurt from buffer tank to packaging machine. This is through a variable speed metering pump to continuously beat these ingredients into the yogurt, after mixing device. The design of the mixing device is static and hygienic, and ensures that the fruit and yogurt are thoroughly mixed. The fruit metering pump and the yoghurt feeding pump operate synchronously.

|

Technical Parameters

|

|

|

|

|

||||

|

Raw material

|

|

Fresh milk& milk powder

|

|

|

||||

|

Final product

|

|

Yogurt

|

|

|

||||

|

Capacity

|

|

200-10000LPH

|

|

|

||||

|

Productivity

|

|

97%

|

|

|

||||

|

Plant need

|

|

200-800㎡

|

|

|

||||

|

Workers need

|

|

3-7

|

|

|

||||

Milk fermentation system

Milk fermentor, made of food grade stainless steel, is totally enclosed with heating and cooling interlayer to avoid secondary pollution of yogurt. Equipped with automatic control box, it can accurately control the temperature in the tank, improve the fermentation efficiency of yogurt, and ensure the quality stability of each batch of yogurt.

Our strengths:

*It can be designed according to the special requirements of users

*Multiple products can be produced on the same production line

*It can produce high quality products and keep nutrients

*Aromatic substances can be added and mixed precisely

*Extend the shelf life of products

*Large output and small loss

*Application of high technology to save energy consumption

Product Display

Hot Searches