- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

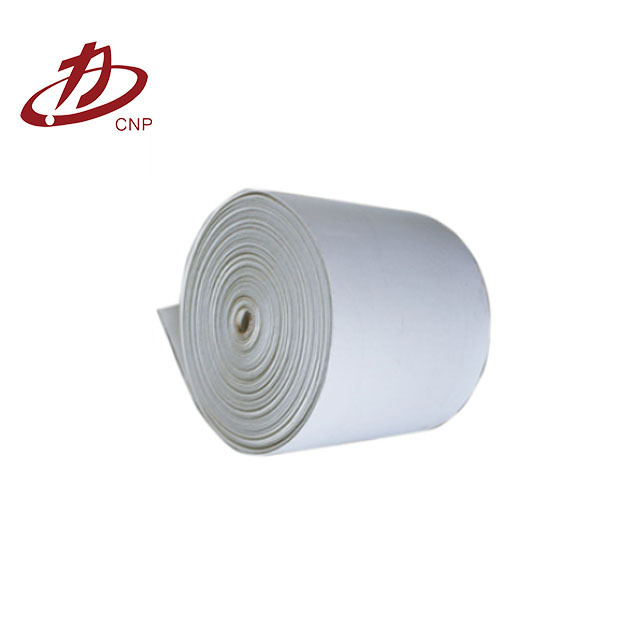

polyester textile air slide fabric india airslide fabric

-

Weft tensile strength:

-

3000N/cm @ 2cm length sample

-

Warp tensile strength:

-

6000N/cm @ 2cm length sample

-

Weight:

-

4000g/m2

-

Product discribe:

-

100% Filament polyester canvas

-

Width:

-

100 - 2800mm

-

Warranty::

-

2 years from the date of load on board

-

Air pressure loss:

-

350pa @ 400m3/m2/h

-

Working temperature:

-

-60 - 150 degree

-

Short-time working temp.:

-

200 degree

-

After Warranty Service:

-

Online support

-

Local Service Location:

-

None

Quick Details

-

Core Components:

-

NONE

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

CNP

-

Product name:

-

polyester textile air slide fabric india airslide fabric

-

Weft tensile strength:

-

3000N/cm @ 2cm length sample

-

Warp tensile strength:

-

6000N/cm @ 2cm length sample

-

Weight:

-

4000g/m2

-

Product discribe:

-

100% Filament polyester canvas

-

Width:

-

100 - 2800mm

-

Warranty::

-

2 years from the date of load on board

-

Air pressure loss:

-

350pa @ 400m3/m2/h

-

Working temperature:

-

-60 - 150 degree

-

Short-time working temp.:

-

200 degree

-

After Warranty Service:

-

Online support

-

Local Service Location:

-

None

Cement polyester fabrics pneumatic air slide belt

1. Good at unloading chute part.

2. good working life

3. Solid woven struture

4. Good resistance to chemicals

5. More working life than 100% spun polyester belt

Sell Air Slide Belt for Cement Plant/Polyester Fabrics/Pneumatic Conveyor Belt/Airslide Fabrics Air slide fabric for 100% filament polyester

INTRODUCTION

We provide Airslide belt for conveying bulk material by air gravity. The main use of Airslide belt is discharging, declining transportation or homogenizing the powder or small granular material in quiescent condition. Our airslide belt is named as Airslide fabric, Airslide membrane, Air slide cloth, Air slide canvas, Air permeable fabric, and Fluidization cloth, fluidising fabric, etc by our customer. We adopt 100% polyester for airslide fabric material.

Our fabrics can be used at temperatures between -60°C and +150°C. The airslide fabrics are made from polyester yarns.

We are also, however, able to weave fabrics to our customers' specific demands for air permeability and mechanical strength.

Advantages

- No moisture absorption

- No caking

- Resistant to rotting and decomposition

- Complete unloading without residues

- Consistent fluidization over the complete surface

- Good resistance to abrasion

- Low wear and therefore longer life

- Low shrinkage even when used under hot and humid conditions

Working principle

In cement plant:

An Airslide belt is in the middle of a chute. Powder material will come into the chute above Airslide belt. Material will flow to the chute lower side as pneumatic blower down Airslide belt. That's why we say Airslide belt can move powder material because of the wind power. And then, the rest wind will go out from the top of the chute. Through the moving, no parts moved except powder material. So that it can spare more energy and maintain cost, etc.

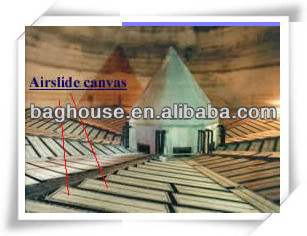

In fluidization silo:

In fluidization silo:

Our Airslide canvas is installed on the surface of the silo bottom. It is supplied for installation as aeration units on the sloped conical bottoms of bins and silos to aid in the withdrawal of dry relatively free-flowing material.

Each Airslide aeration unit package consists of 200mm open-type. Airslide conveyor units in lengths of 1.5 or 3m depend on the slope length of the conical storage area. Some spoke patterns are normally used with materials which have good fluidization characteristics. Others spoke patterns provide maximum aeration for difficult materials which can be fluidized.

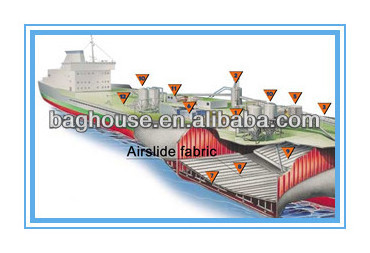

In cement vessel's hold:

In cement vessel's hold:

The sloped bottom of the cargo hold is covered with fluidizing panels. Our airslide fabric is on the surface of fluidizing panels. Rotary piston blowers supply the panels with oil-free compressed air and make the cement flow to the lowest point, where the discharge gate is installed.

Air slide fabric for particulate material transportation. Another name: Air slide cloth, pneumatic fluidizing canvas

Working occasions

In industry

Power Stations

Filtered dust

Flue ash, discharging flue ash

Coal dust

Building and Construction

Cement, furnace dust, gypsum, limestone, finely ground quartz,

Calcium hydroxide, lead monoxide, quicklime, acid crystals,

Pure clay, phosphates, magnesite concentrate, finely ground

fluorid, production of aluminum

Chemical Industry

Thomas meal (Fertilizer)

Rubber compounds, sinter dust, catalysts

Sodium sulfate

Soap powder

In machinery:

Silos / Tanks

Discharging systems

Warehouse units

Mixing equipment

Homogenizing systems

Chute Bottoms

Conveyor systems

Ventilator systems

Aeration systems

Vehicles

Silo truck discharging cones

Railway wagon discharging cones

Vessel aeration & discharging bottoms

Container aeration & discharging bottoms

Powder Coating Machinery

Bottoms for sinter basin

Specification data:

Raw Material =100% spun fiber polyester

Weight in average = 4000 g/m

2

Thickness = 5mm

Mean Air Permeability = 400 m

3

/m

2

h @350H

2

O

Pressure: 2000pa for middle air resistance

4000pa for high air resistance

Breaking Strength- Warp=>6000 N/5cm X 20cm

Breaking Strength- Weft= >3000 N/ 5cm X 20cm

Breaking Elongation - warp=<5%

Breaking Elongation -weft=<5%

Max Width: 2800mm

Operating Temperature < 150 deg.C

Recommended Maximum Continues <180 deg.C

Recommended Maximum Surge = 180 deg.C

********************

Please click the following product name to view more product details:

SINGLE BAG FILTER ROUND PULSE FILTER CENTRIFUGAL FAN REVERSE BLOW FILTER DUST COLLECTOR

FILTER BAG / FILTER CAGE SCREW CONVEYOR AIRSLIDE FABRIC / HOSE PULSE VALVE UNLOADER FILTER FELT

********************

We provide all kinds of standard export packing for cargo protection. The bag filter will be fixed on the container. The filter bag and cages will be fixed in corrugated box and steel framed structure.

1. Enquiries quickly reply within 24 hours.

2. After-sales service, rapid response, the engineer installation guide. The feedback problems will be replied within 24 hours. We can arrange professional engineers arrived at equipment location within 48 working hours for problem solved.

3. The dust collector design according to the specific condition of dust removal technology. The wind network project design for all system. To be the optimal structure design.

4. The lowest equipment price whole network in alibaba Welcome to rate of the price. If our price is higher, we will return twice of our quoted price difference to you. Please prompt before sign the contract with us. Due to our good faith principle.

5. The bag filter equipment over 20 years working life.

6. Associated with equipment spare parts, ensure the replacement parts within 20 years.

7. If accessories stop production or update, to ensure that the replacement parts can be normal use, and keep noticed one year before the spare parts stop production.

8. Ensure easy operation and absolutely no worries about future

Please don't hesitate to contact me if there is anything we can do for you! We would like to help you slove the dedusting problem and supply the equipment to you

Skype: cnp_crystal

Whatsup; +86 13821106147

Send your inquiry to us! feedback with 12hours. cnp_crystal at www. cnp-baghouse.com.