- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Other Country

-

Brand Name:

-

Dixin

-

Voltage:

-

380v

-

Weight:

-

2.5 kg

-

Marketing Type:

-

New Product 2023

-

Raw material:

-

Galvanized Sheet

-

Usage:

-

Building

-

Thickness:

-

0.3-1mm

-

Motor brand:

-

Detal

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Application:

-

Construction Panel

-

Certification:

-

ISO

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

8-12m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Other Country

-

Brand Name:

-

Dixin

-

Voltage:

-

380v

-

Weight:

-

2.5 kg

-

Marketing Type:

-

New Product 2023

-

Raw material:

-

Galvanized Sheet

-

Usage:

-

Building

-

Thickness:

-

0.3-1mm

-

Motor brand:

-

Detal

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Application:

-

Construction Panel

-

Certification:

-

ISO

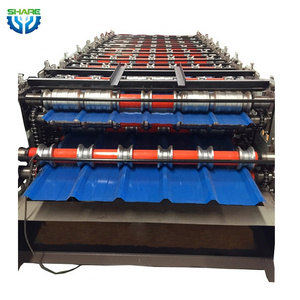

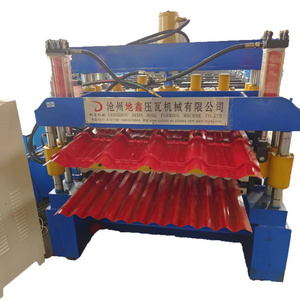

Professional production recommend 3D wall panel metal sheet roll forming machine

The three-dimensional board produced by the three-dimensional trigger can be used not only for the door decoration of the storefront, but also for interior and exterior wall decoration and ceiling decoration. The 3D board is different from our common stereo soft pack material. The three-dimensional board adopts galvanized sheet as raw material, relying on the original mature technology, the color steel three-dimensional board is lower in price than the similar plastic three-dimensional gusset plate, the material is light, the quality is good, the paint is not easy to fall off, it is not easy to be deformed, anti-aging, anti-corrosion Strong, durable and long life. Rich colors, flexible combination, variety of fancy, novel, easy to install.

Technical parameter

If you have specific requirements, that's no problem,We can meet all your needs.

| No. | ||

| 1 | Suitable material | color steel sheet, galvanized steel sheet, aluminium sheet |

| 2 | Material width | 1250mm or as your required |

| 3 | Material thickness | 0.3-0.8 or as your required |

| 4 | Working speed | 8-12m/min, can be 20-25m/min |

| 5 | Main motor power | 5.5kw with cycloidal with reducer |

| 6 | Hydraulic pump power | 4kw |

| 7 | Electrical control system | PLC control system with inverter |

| 8 | Shaft diameter | 75mm |

| 9 | Roller station | 15 rows, depend on your panel profile drawing |

| 10 | Roller | high grade 45# steel, hard chrome plating |

| 11 | Working time | 24 hours |

| 12 | workers | 1-2 only |

| 13 | Cutting head material | Cr 12 mould steel with quenched treatment |

| 14 | Voltage | 380V 3Phase 50Hz or as your required |

| 15 | Weight | 3.5T |

| 16 | The machine size | 7000mm*1500mm*1500mm |

We use the best quality raw materials, so you can trust our quality.Machines are not only economical in price, but also guaranteed in quality.

Different type