- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

780*350*332 MM

-

Year:

-

2021

-

Power (kW):

-

7.5 kW

-

Weight (KG):

-

95.51 KG

-

Product name:

-

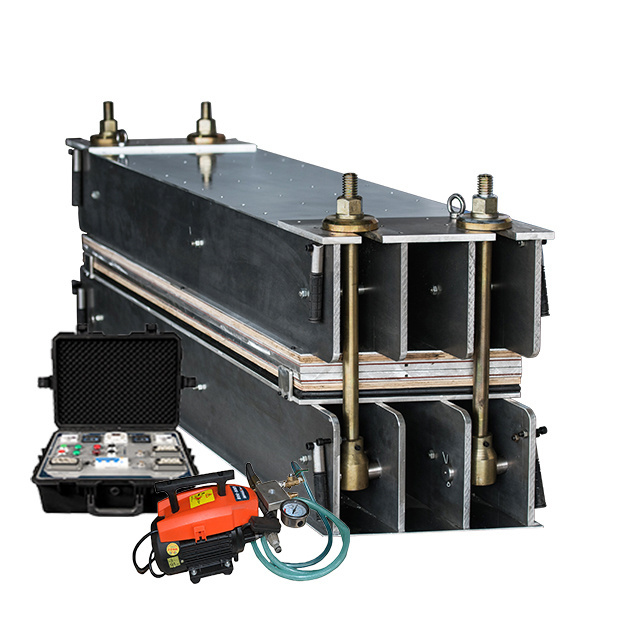

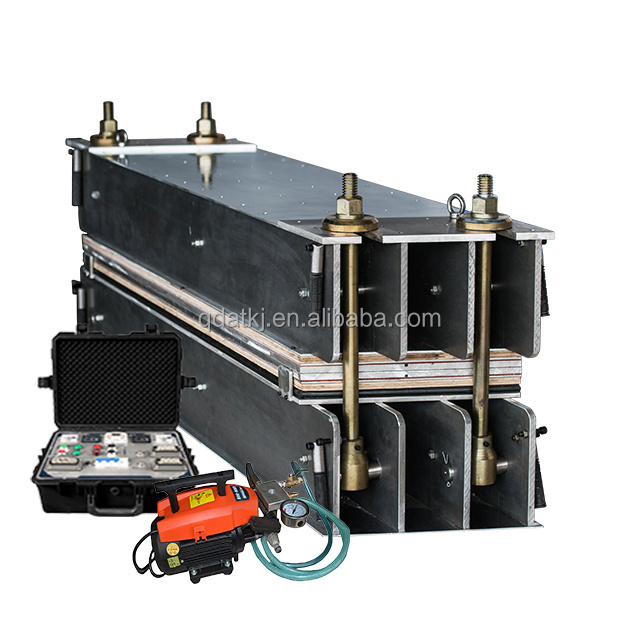

Conveyor belt welding vulcanizer press

-

Function:

-

Conveyor belt joint vulcanizer press

-

Application:

-

Conveyor belt vulcanization splicing press

-

Machine Type:

-

Conveyor belt vulcanizing machine

-

Material:

-

High strength aluminum alloy

-

Belt Vulcanizing Temperature:

-

145℃

-

Working Pressure:

-

0~2MPA

-

Heating Time:

-

Less Than 25 Minutes

-

Curing Time Set Adjustable Range:

-

0-99 minutes

-

Max Conveyor Belt Width:

-

500-3500mm

-

Marketing Type:

-

New Product 2021

-

Certification:

-

CE ISO

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

ANTAI

-

Voltage:

-

Customer Request

-

Dimension(L*W*H):

-

780*350*332 MM

-

Year:

-

2021

-

Power (kW):

-

7.5 kW

-

Weight (KG):

-

95.51 KG

-

Product name:

-

Conveyor belt welding vulcanizer press

-

Function:

-

Conveyor belt joint vulcanizer press

-

Application:

-

Conveyor belt vulcanization splicing press

-

Machine Type:

-

Conveyor belt vulcanizing machine

-

Material:

-

High strength aluminum alloy

-

Belt Vulcanizing Temperature:

-

145℃

-

Working Pressure:

-

0~2MPA

-

Heating Time:

-

Less Than 25 Minutes

-

Curing Time Set Adjustable Range:

-

0-99 minutes

-

Max Conveyor Belt Width:

-

500-3500mm

-

Marketing Type:

-

New Product 2021

-

Certification:

-

CE ISO

Products Description

|

Product Name

|

2 Piece Light Weight Conveyor Belt Hot Splicing Vulcanizer Machine

|

|

|

Keywords

|

Conveyor belt welding vulcanizer press

|

|

|

Type

|

Conveyor belt vulcanizing machine

|

|

|

Size(L*W*H mm)

|

780*350*332 mm

|

|

|

Application

|

Conveyor belt hot vulcanizing press

|

|

|

Function

|

Conveyor belt vulcanization splicing press

|

|

|

2 Piece Light Weight Conveyor Belt Hot Splicing Vulcanizer Machine

|

|

|

FEATURES

• Signature ANTAI “Pressure Bag” uniform pressure system.

• Custom “Extruded Plank” cooling system within platens.

• Innovative “Silicone Element” fast heating system.

• Custom “Extruded Plank” cooling system within platens.

• Innovative “Silicone Element” fast heating system.

• Automatic mute pressure pumps for operating pressures above 20kg/cm

2

(2.0MPa).

• ZLJ platens are built to order with all dimensions offered to accommodate various belt widths.

• DELIXI electrical apparatus element assembled into insulating and waterproof control panel.

• All electrical systems are CE, CSA and UL approved.

• DELIXI electrical apparatus element assembled into insulating and waterproof control panel.

• All electrical systems are CE, CSA and UL approved.

Click

here for more information !!!

Application

It's a vulcanizing equipment and tool for repairing & splicing of conveyor belt.

The belt vulcanizer is dependable, lightweight and portable machine, which is widely used in the field of metallurgy, mining, power plants, ports, building materials, cement, coal mine, chemical industry,

It's a vulcanizing equipment and tool for repairing & splicing of conveyor belt.

The belt vulcanizer is dependable, lightweight and portable machine, which is widely used in the field of metallurgy, mining, power plants, ports, building materials, cement, coal mine, chemical industry,

etc.

It suits for various conveyor belts, such as EP, Rubber, Nylon, Canvas and Steel cord belt, etc.

It suits for various conveyor belts, such as EP, Rubber, Nylon, Canvas and Steel cord belt, etc.

SPECIFICATIONS

1. Voltage: 220V 380V 415V 525V 660V 1140V 50HZ 60HZ(Customize available according to your requirement)

2. Quick water cooling device: 15 minutes From 145 ℃down to 80 ℃or even lower

3.Cooling source: Water or Air

4.Heating source: Electricity

5. Heating time: from room temperature to vulcanization temperature need less than 20 minutes

6. Heating plate surface temperature difference: ± 1 ℃

7. The temperature adjustment range: 0 ~ 200 ℃(custom)

8. Vulcanization pressure: Max 2.5MPa.

9. Curing temperature: 0 ~ 99min (according to the thickness of the belt to adjust)

1. Voltage: 220V 380V 415V 525V 660V 1140V 50HZ 60HZ(Customize available according to your requirement)

2. Quick water cooling device: 15 minutes From 145 ℃down to 80 ℃or even lower

3.Cooling source: Water or Air

4.Heating source: Electricity

5. Heating time: from room temperature to vulcanization temperature need less than 20 minutes

6. Heating plate surface temperature difference: ± 1 ℃

7. The temperature adjustment range: 0 ~ 200 ℃(custom)

8. Vulcanization pressure: Max 2.5MPa.

9. Curing temperature: 0 ~ 99min (according to the thickness of the belt to adjust)

Usually 10mm~25mins, 20mm~35mins

10. Automatic mute pressure pump

11. Automatic control panel: insulating and waterproof, security alarm, Auto power-off when reach the vulcanization temperature.

Upgrading explosion proof control box option available.

10. Automatic mute pressure pump

11. Automatic control panel: insulating and waterproof, security alarm, Auto power-off when reach the vulcanization temperature.

Upgrading explosion proof control box option available.

Our Advantages

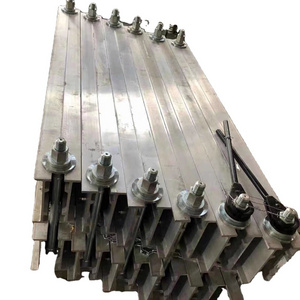

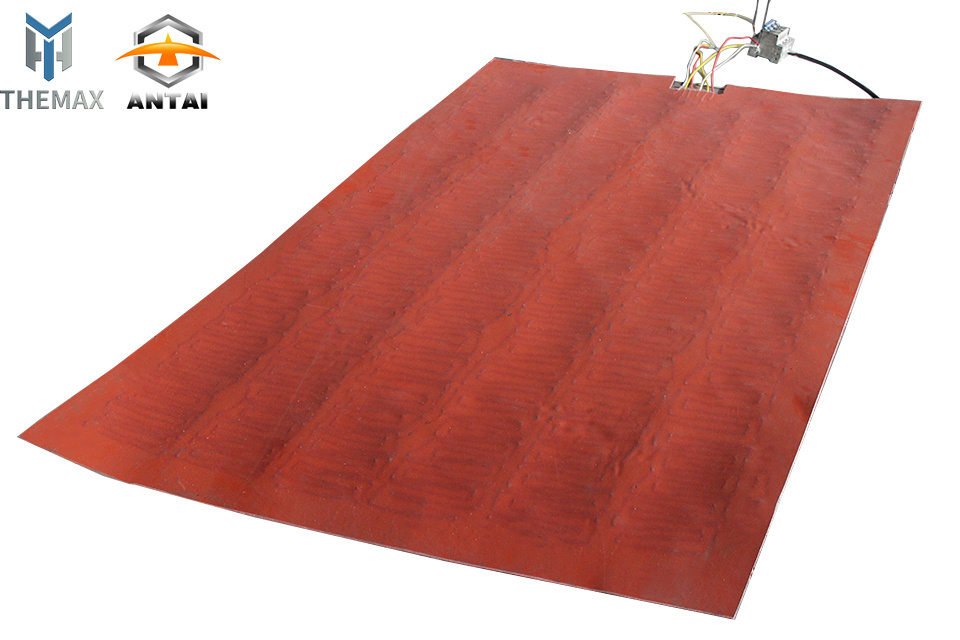

HEATING PLATEN

Custom extruded plank, silicone heating elements (up to 180°C/356°F), and durable composite insulating packaging are used to

construct a flexible platen that contours to belt irregularities.

It takes 15~25mins rise up to vulcanizing temperature (about 145°C).

The flush “quick connect” make smooth profile. Recessed power connections are sealed for moisture resistance.

construct a flexible platen that contours to belt irregularities.

It takes 15~25mins rise up to vulcanizing temperature (about 145°C).

The flush “quick connect” make smooth profile. Recessed power connections are sealed for moisture resistance.

PRESSURE SYSTEM

Signature ANTAI “Pressure Bag” uniform pressure system is lighter up to 4 times than the outdated pressure bag.

The pressure bag can reach full expansion in one time and ensure the uniform pressure up to 3.0MPa.

The pressure bag can reach full expansion in one time and ensure the uniform pressure up to 3.0MPa.

PRESSURE PUMP

Automatic mute pressure pump own the features as smaller size, lighter weight and high impact-resistance. Compared with the manual pump, the operating pressure can be 23kg/cm2 (2.3MPa).

COOLING SYSTEM (Option Available)

Custom “Extruded Plank” cooling system within platens is made by several cuprum pipelines, it only takes about 20mins to drop the temperature down to 60°C.

AUTOMATIC CONTROL BOX

With automatic temperature control, security alarm and automatically switch off the power. The control box can monitor the temperature of 3-5 different points on each heating platen at the same time to ensure the result of jointing.

Main Parts

ZLJ conveyor belt vulcanizing machines can be used by one or multiple combinations according to the joint length of the belt.The main configuration of a single vulcanizing machine is as following:

|

Name

|

Amount

|

|

The whole machine

|

1 set

|

|

Ratchet wrench

|

2 piece

|

|

steel pad

|

1 set

|

|

Clamping device

|

1 set

|

|

Electric control box

|

1 set

|

|

Power cable

|

1 root

|

|

Control cable

|

2 root

|

|

Thermal resistance

|

2 pieces

|

|

Water pump

|

1 set

|

|

Pressure pipe

|

3 roots

|

Model and Specifications

1.According to the Width of conveyor belt is divided into:500,650,800,1000,1200,1400,1600,1800, 2000,2200 (mm).

2.According to the Joint Length of conveyor belt is divided into :250,300,350,400,500,600,700,800,1000,1200(mm).

3.According to Hot plate shape: rectangular-72°, parallelogram -90°.

4.According to Voltage: 220V,380 V,440V,660V or as customized.

5.According to the cooling method can be divided into:Fast water cooling type and natural cooling type.

4.According to Voltage: 220V,380 V,440V,660V or as customized.

5.According to the cooling method can be divided into:Fast water cooling type and natural cooling type.

Technical Characteristics

1.Heating: electric heating type.

2.Pressurized: hydraulic type.

3.Supply voltage: 1140 V,660 V,450 V,415 V,380 V,220 V,50 Hz or as customized.

4.Heating power of a single heating plate per unit area ≥ 7000 W / ㎡.

5.Equipped with digital temperature control system, vulcanizing temperature adjustable 0-199 °C.

6.Heating time(room temperature raise to 145°C)≤25 mins.

7.Vulcanization pressure can be set to≤2 MPa.

8.Automatic control of temperature rise, heat preservation and temperature limit protection.

2.Pressurized: hydraulic type.

3.Supply voltage: 1140 V,660 V,450 V,415 V,380 V,220 V,50 Hz or as customized.

4.Heating power of a single heating plate per unit area ≥ 7000 W / ㎡.

5.Equipped with digital temperature control system, vulcanizing temperature adjustable 0-199 °C.

6.Heating time(room temperature raise to 145°C)≤25 mins.

7.Vulcanization pressure can be set to≤2 MPa.

8.Automatic control of temperature rise, heat preservation and temperature limit protection.

Technical Parameters (Reference)

(Except for 830 mm, 1000 mm and other conventional sizes, any non-standard size is accepted.)

Product packaging

We use fumigation-free box as our packing box.It has clean and tidy appearance,easy to load and unload.Comply with the export standards of the customs.

Customer Photos

Our Plant

Certifications

We are the Direct Manufacturer of conveyor belt vulcanizing equipment. Our company is the direct manufacturer supplier in China for the production of the pressurized bag. ALMEX STYLE available,with lower ANTAI price.

Yes! We promise you the lowest price in China. In case of the higher price you may get from our domestic trading company Please keep in touch with me.

Contact with me

If you need the latest catalogue of our conveyor belt vulcanizing press or have any problem about our products,please feel free to contact with me. I will do my best to provide you our professional service.

Here is my EMAIL address:

sherry@antai86.com (Sales manager of ANTAI OVERSEAS DPT)

TEL: +86 15665751353

Whatsapp/Wechat: +86 15665751353

Hot Searches