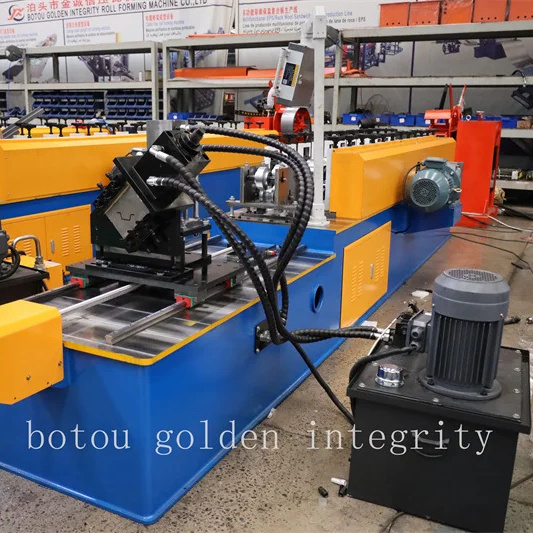

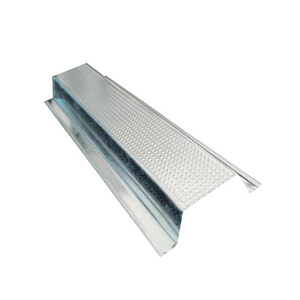

Control The Quantity And Cutting Length Automatically

Input The Production Data(Production Batch,pcs,Length,etc.)On The Touch Screen ,

It Can Finish The Production Automatically.

Combined With: PLC, Inverter, Touch Screen, Encoder, etc

Optional 360°rotating console , that greatly saves manpower.