- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Cold Room

-

Design Style:

-

Industrial

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Shunwei

-

Model Number:

-

cold storage shift door

-

Color:

-

Customized Color

-

Thickness:

-

50/75/100/120/150/200mm

-

Thermal Insulation:

-

5.0.018~0.029W/(M/K)

-

Surface Material of Sliding Door:

-

9.PPGI/Embossed Aluminium/Stainless Steel

-

Safety Device:

-

Emergency Escape Lock

-

Cold Room Door Open Style:

-

Sliding

-

Size:

-

Customized Size

-

Advantage:

-

Heat Insulating

-

Usage:

-

cold room/cold storage

-

Core Components:

-

Bearing

Quick Details

-

Door Material:

-

Steel

-

Feature:

-

Thermal Insulation

-

Main Material:

-

Polyurethane

-

Application:

-

Cold Room

-

Design Style:

-

Industrial

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Shunwei

-

Model Number:

-

cold storage shift door

-

Color:

-

Customized Color

-

Thickness:

-

50/75/100/120/150/200mm

-

Thermal Insulation:

-

5.0.018~0.029W/(M/K)

-

Surface Material of Sliding Door:

-

9.PPGI/Embossed Aluminium/Stainless Steel

-

Safety Device:

-

Emergency Escape Lock

-

Cold Room Door Open Style:

-

Sliding

-

Size:

-

Customized Size

-

Advantage:

-

Heat Insulating

-

Usage:

-

cold room/cold storage

-

Core Components:

-

Bearing

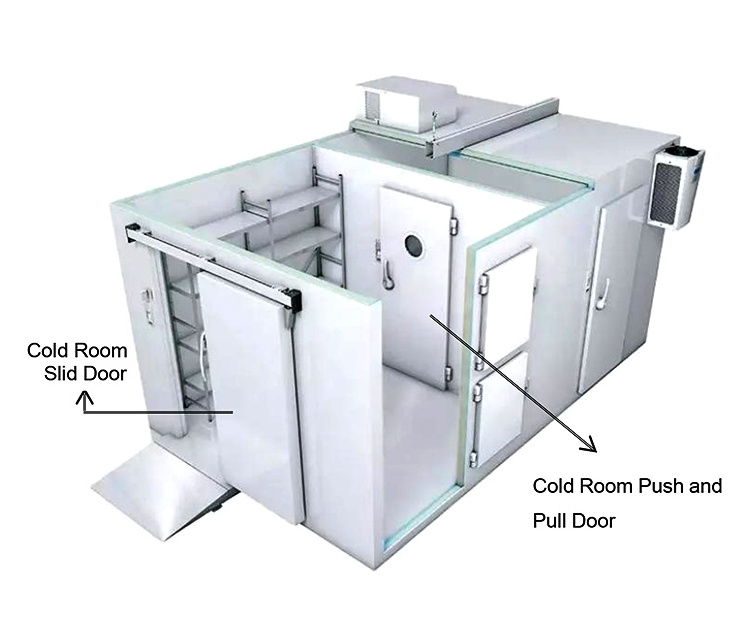

Products Description

|

Application

|

Cold storage, low temperature processing workshop, adiabatic device, the door body size is moderate, open frequently

|

|

Length Width Height

|

Customized by guest, We can give you a professional opinion.

|

|

Temperature Range

|

-45℃~+50℃

|

|

Panel process

|

With polyurethane and panel overall foaming, smooth appearance, good thermal insulation performance.

|

|

Panel material

|

Stainless steel, color steel plate, embossed aluminum plate, etc

|

|

Thickness of Panel

|

75mm 100mm 120mm 150mm

|

Cold Storage Analysis Diagram

Process flow

Production Process

Pressed

According to the customer's choice of steel coil and the direction of use, after precision instrument rolling, finally formed corrosion resistant, acid resistant, water resistant door type.

Measure

Strict calculation, no error according to the customer's choice of length, width and height to customize the size of the door, in this step reflects the spirit of craftsmanship.

Assemble

At this step, the door seal is assembled. Our thickness is 75/100/150/200mm, which can ensure the insulation capacity according to the direction of use.

Measure Again

Now that the casing has been assembled, the next step is to make sure that the core is insulated with a precise polyurethane feed.

Foam

The exquisite mold is waiting for the entrance of the door. In this step, polyurethane feeding will start. We choose Wanhua and BASF.

Accessories

A cold storage door with thermal insulation performance was born, and the next step is to prepare some installation equipment for it.

Application

Packaging&Delivery

1. Plastic film packaging

2. Qingdao, Shanghai, Guangzhou ports, subject to designation

3. Received the goods within 45 days after paying the final payment

Advantage Products

Hot Searches