- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Kunzite

-

Voltage:

-

110/220v,50/60hz

-

Power:

-

2.2KW / 1.5KW / 0.1KW

-

Dimension(L*W*H):

-

387*316*255mm

-

Weight:

-

23 kg

-

Finished Products:

-

paper recycling systems

-

Name:

-

cushion material packaging material

-

Product name:

-

paper pulper machine

-

Output paper:

-

packaging filler

-

Keyword:

-

filling paper

-

Usage:

-

paper honeycomb packaging

-

Machine type:

-

big/medium/small

-

Function:

-

honeycomb paper manufacturing

-

Application:

-

Waste paper recycling

-

Raw material:

-

waste paper, kraft paper, A4 paper

Quick Details

-

Production Capacity:

-

3 m/min

-

Product Type:

-

honeycomb paper cutter

-

Processing Type:

-

honeycomb cardboard line

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Kunzite

-

Voltage:

-

110/220v,50/60hz

-

Power:

-

2.2KW / 1.5KW / 0.1KW

-

Dimension(L*W*H):

-

387*316*255mm

-

Weight:

-

23 kg

-

Finished Products:

-

paper recycling systems

-

Name:

-

cushion material packaging material

-

Product name:

-

paper pulper machine

-

Output paper:

-

packaging filler

-

Keyword:

-

filling paper

-

Usage:

-

paper honeycomb packaging

-

Machine type:

-

big/medium/small

-

Function:

-

honeycomb paper manufacturing

-

Application:

-

Waste paper recycling

-

Raw material:

-

waste paper, kraft paper, A4 paper

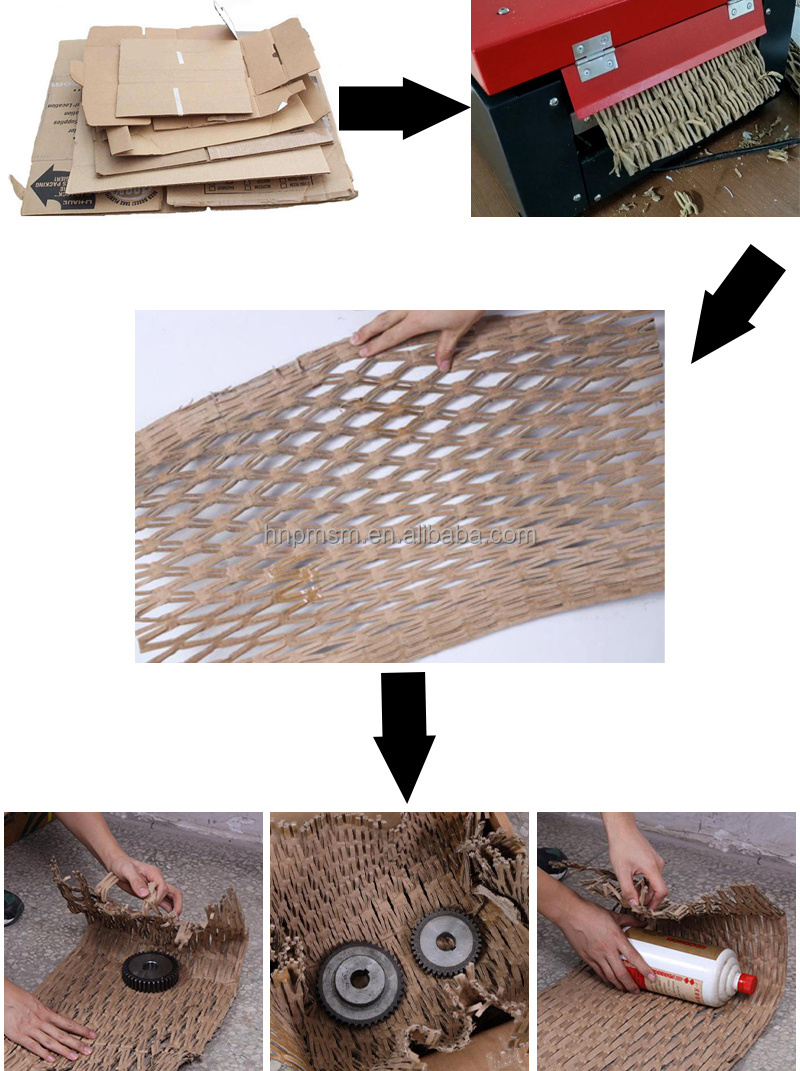

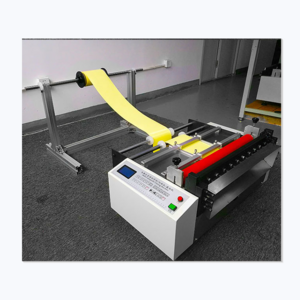

Widely-Used Waste Paper Cutting Machine Low Price Paper Crinkle Machine Applied To Paper Cushion Packaging

|

Model |

SZ-425 |

SZ-325 |

SZ-25 5 |

|

Cutting width |

425mm |

325mm |

25mm |

|

Cutting thickness |

13 mm |

7 mm |

6 mm |

|

Applicable waste paper |

5-7 layers of corrugated

|

3-5 layers of corrugated

|

3-5 layers of corrugated

|

|

Paper shredding speed |

1 3 m/min |

7 m/min |

6 m/min |

|

Noise |

60db |

60db |

60db |

|

Power supply voltage |

380v , 50hz |

220v /110v, 50hz |

220v /110v, 50hz |

|

Power |

2. 2 kw |

1. 5 kw |

0. 1 kw |

|

Machine size |

623*385*886mm |

487*378*826mm |

38 7 *3 16 *25 5 mm |

|

Weight |

1 27 kg |

78 kg |

2 3 kg |

Expanding and cutting machine use: to use waste paper, shredded and used for express packaging of fragile, fragile, and need-to-fill items.

Four major advantages:

1,Environmental protection

The packaging fillings of paper products can be recycled and have no pollution source.

2, Reduce costs

After being processed into a fluffy packaging filler by a cardboard expanding machine, the value will be about 10 times the original value, which can greatly reduce costs for enterprises.

3, Waste utilization

It can handle irregular waste cardboard, unqualified cartons, color boxes, cartons, with or without printing. Not only can these waste products be recycled, but also can be recycled, which greatly solves the more difficult problems for business managers.

4, Wide range of uses

The reticulated corrugated cardboard processed by the cardboard expansion machine can be widely used as a packaging filler for the packaging and logistics of precision instruments, meters, electrical appliances, ceramics, glass, handicrafts, cosmetics, furniture and other items.

1. Lead time

About 1 to 5 days for spot goods and 14 days for customized items, also depending on quantity.

2. Package

(1) Pack all goods according to customers' requirements, like putting item bar code, FBA label, and so on.

(2) Standard export carton (can be wrapped with non-woven bag)

3. Delivery

(1) By courier, air, sea, railway or land. If necessary, DDP can be handled.

(2) Shipping method is affordable and stable. We have advantageous logistics to USA, Canada, European coutries, Southeast Asia and

some African countries. Best shipping way will be suggested according to final gross weight and volume.

(3) Global DDP logistics service to FBA warehouse can be provided.