Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

customized

-

Dimension(L*W*H):

-

2.6*1.0*1.0m

-

Weight:

-

350 KG

-

Machinery Function:

-

OVEN

-

Output product name:

-

Conveyor oven

-

Name:

-

conveyor chain oven

-

Application:

-

bake the tortilla, pita , roti or other bread

-

Energy:

-

LPG gas or electric

-

Temperature Range:

-

0~550 Degrees

-

Capacity:

-

customized

-

Bake the bread size:

-

customized

-

Packing:

-

Standard Wooden Case

-

Advantage:

-

Simple Operation

-

MOQ:

-

1 Set

-

whatsapp:

-

+8618737189043

Quick Details

-

Brand Name:

-

hanchuang

-

Place of Origin:

-

Henan, China

-

Voltage:

-

380V

-

Power:

-

customized

-

Dimension(L*W*H):

-

2.6*1.0*1.0m

-

Weight:

-

350 KG

-

Machinery Function:

-

OVEN

-

Output product name:

-

Conveyor oven

-

Name:

-

conveyor chain oven

-

Application:

-

bake the tortilla, pita , roti or other bread

-

Energy:

-

LPG gas or electric

-

Temperature Range:

-

0~550 Degrees

-

Capacity:

-

customized

-

Bake the bread size:

-

customized

-

Packing:

-

Standard Wooden Case

-

Advantage:

-

Simple Operation

-

MOQ:

-

1 Set

-

whatsapp:

-

+8618737189043

Industrial Automatic Pita Bread Making Machine +8618737189043

Precautions of conveyor oven

1. The tunnel oven should be placed in a clean indoor level. Keep it dry, prevent moisture and moisture, and prevent corrosion.

2. Pay attention to safe use of electricity, install a power circuit breaker with sufficient capacity according to the power consumption of the tunnel oven, select enough power supply wires, and have a good grounding wire.

3. Check the voltage before using the tunnel oven. The required voltage for the gas oven-heated tunnel oven is 220V or 380V. The required voltage for the electrically heated tunnel oven is 380V (three-phase power), according to the power consumption of the tunnel oven. Install a power circuit breaker of sufficient capacity, select enough power leads, and also do grounding work.

4. There must be a certain space for the tunnel oven to be placed. There must be a certain distance from the wall. It is recommended that the distance be 1.5M or more.

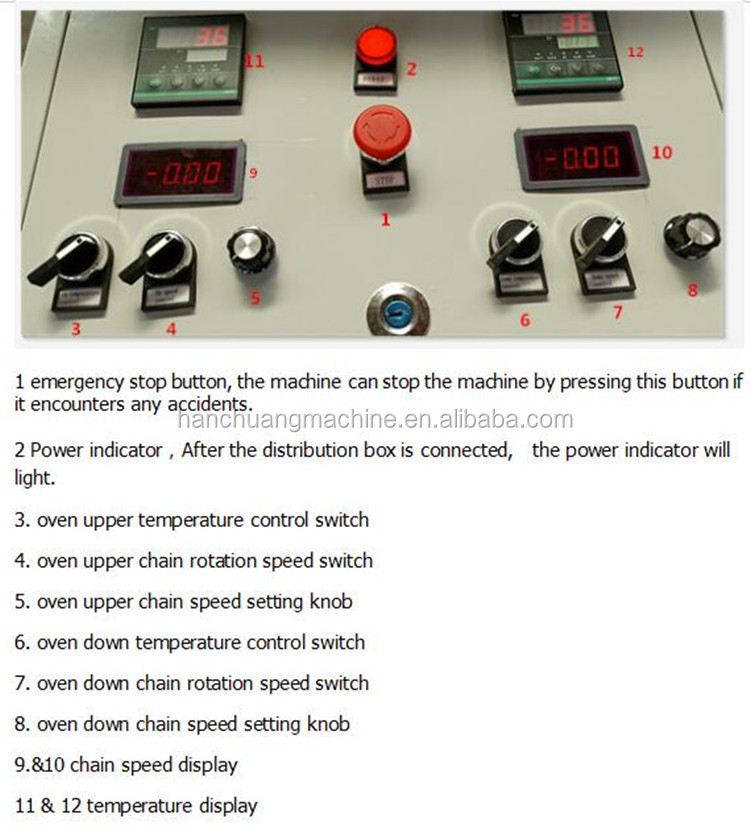

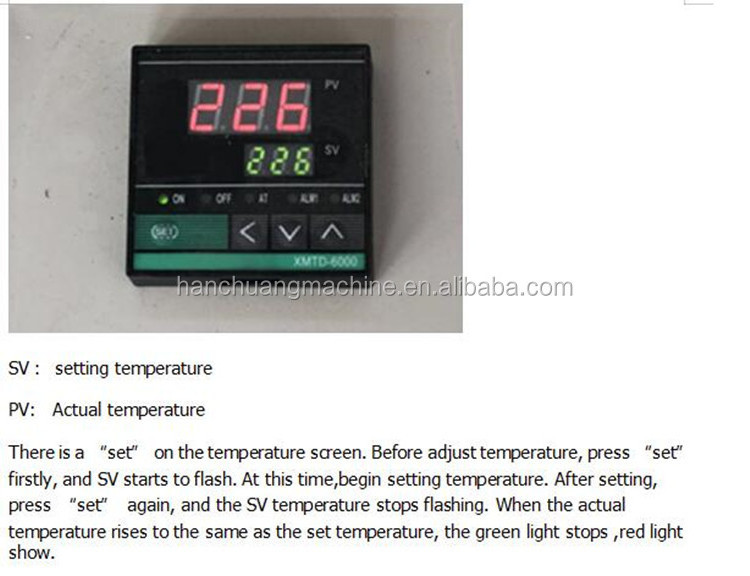

5. After all the inspections are completed, turn on the power to turn on the tunnel oven main switch, respectively open the upper and lower chain conveyor belt operation switch, and let the conveyor belt run at an appropriate speed (generally recommended to adjust to about 3.00) to facilitate uniform heating. Heat the chain conveyor belt. The gas tunnel furnace oven needs to open the gas pipeline switch and open the gas heating switch. For the first time, the regulating valve of each gas grate should be adjusted separately, and the valve of the grate state adjustment valve should be observed to the appropriate position. In the future, it is no longer necessary to adjust the individual grate regulating valves separately. The electric heating tunnel oven can be turned on simply by turning on the heating switch. Then the user can set the temperature of the upper and lower layers separately. After the temperature reaches the set temperature, the operation switch of the skinning machine can be turned on, and the running speed can be adjusted to be synchronous with the chain conveyor belt or a little slower.

6. If the gas tunnel oven is not ignited when it is ignited by an individual, press the one-button auxiliary ignition button to observe that the grate has been ignited.

7. Before turning on the heating switch, remember to first open the chain conveyor belt operation switch to prevent the local temperature of the chain conveyor belt from being too high, causing deformation and other abnormalities.

8. After the above work is ready, the items can be placed in the tunnel oven, and then the temperature and speed of the suitable sample baking are adjusted, and the tunnel oven enters the working state.

9. After the baking work is completed, the heating source is cut off first, and the gas tunnel furnace oven needs to close the gas pipeline switch at the same time. When the temperature drops below 70 degrees, the power can be turned off and the conveyor can be stopped.

10. When using the tunnel oven, the temperature should not exceed the maximum operating temperature of the tunnel oven, and the general oven is below 350 degrees.

11. When working, remember not to touch the baked goods directly with your hands. Use special tools or gloves with isolation gloves to remove the baked goods to avoid burns.

Introduction of the oven operation

Shutdown notes:

Turn off the temperature of the oven and let the chain run for another 3-5 minutes to prevent the oven chain. After the temperature has dropped, turn off the chain knob and finally turn off the whole machine.

Pictures of the conveyor oven for tortilla pita pizza bread

Packaging & Shipping

1. Testing Machine before package

2. Package : Inside plastic bag, outside wooden case.

3. Shipping: By sea, By air.

By sea: if customer not urgently the machine, we advice by sea, even though by sea took time is long, but by sea reduce much money about the freight, and it is good for customer if the machine is heavy and big size.

By air: it is faster than by sea, but its freight is higher much than by sea, so this kind of type always suggest for light, small size and urgently demand machine.

Pre-sale service

1.Related machines’s technical parameter will be supplied to customer.

2.According to customer’s factory size, factory layout can be provided in advance.

3. According to customer’s material cost, general formulation can be prepared well.

4.Special machine can be supplied as customer’s request.

5.Professional Advice about Market, machines, processing , materials, packing can be supplied

6. Suggesting professional ship agent or helping book ship as customer request.

After sale service :

1.Allocation chart as the buyer’s request will be supplied.

2.Operation manual will be supplied after shipment.

3.One year warrantee, life time maintenance with cost price.

4.Free easy broken spare parts will be sent with container .

5.First installation can be done by engineer.

6.Training workers in customer’s factory.