- Product Details

- {{item.text}}

Quick Details

-

Production Speed(Cycles/min):

-

15-35 times/min

-

Core Components:

-

Coffee Cup Lid Machine

-

Air Pressure(MPa):

-

0.6 MPa

-

Heating Power (kW):

-

4 kW

-

Air Comsumption(L/min):

-

3 L/min

-

Water Comsumption(L/min):

-

3 L/min

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HONEST

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

2600*1100*1700mm

-

Weight (T):

-

2 T

-

Power(KW):

-

4

-

Name:

-

Coffee Cup Lid Machine

-

Model:

-

HT-450S

-

Max. Cutting speed:

-

15-35 times/min

-

Materials:

-

HIPS, PS, PVC, PET

-

The biggest molding width:

-

120mm

-

Maximum forming depth:

-

46mm

-

Plastic Lids Making Machine:

-

Plastic Lids Making Machine

-

Dimension:

-

2600*1100*1700mm

-

motor power:

-

4Kw

-

pressure of supply water:

-

0.6MPa

Quick Details

-

Max.Forming Height(mm):

-

46 mm

-

Forming Width (mm):

-

120 mm

-

Forming Length (mm):

-

450 mm

-

Production Speed(Cycles/min):

-

15-35 times/min

-

Core Components:

-

Coffee Cup Lid Machine

-

Air Pressure(MPa):

-

0.6 MPa

-

Heating Power (kW):

-

4 kW

-

Air Comsumption(L/min):

-

3 L/min

-

Water Comsumption(L/min):

-

3 L/min

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HONEST

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

2600*1100*1700mm

-

Weight (T):

-

2 T

-

Power(KW):

-

4

-

Name:

-

Coffee Cup Lid Machine

-

Model:

-

HT-450S

-

Max. Cutting speed:

-

15-35 times/min

-

Materials:

-

HIPS, PS, PVC, PET

-

The biggest molding width:

-

120mm

-

Maximum forming depth:

-

46mm

-

Plastic Lids Making Machine:

-

Plastic Lids Making Machine

-

Dimension:

-

2600*1100*1700mm

-

motor power:

-

4Kw

-

pressure of supply water:

-

0.6MPa

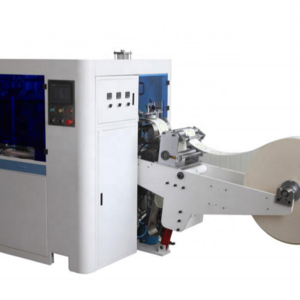

Automatic Plastic Cup Lid Forming Machine / Paper Cup Lid Machine / Coffee Cup Lid Machine

1. Machine introduction of Plastic Lids Making Machine

HT-DB420 Full automatic Lid molding machine, it is the first innovation research and development of new products, according to the market demand and production technology. This machine is a multi-station automatic machinery, has the synchronization is complete forming, punching, cutting, etc.; Solves the problems of food packaging hygiene standards, not only effectively solve the large production of plastic products production funds, labor input, complex production process, low product health and safety problems, and has a wide range of USES, can be applied to metal food medicines and chemical reagents such as PS/PET/PVC plastic products production, appearance beautiful, affordable, deeply welcomed by customers at home and abroad!

Features:

1. Implementation of GMP/QS double standard dust-free clean production, improve product health security, solve the cross contamination.

2. Rolling forming punching blanking winding five station synchronous production, manipulator clamping feeding, compact structure, smooth operation, simple operation.

3. The use of special feeding device, can save electricity 20 times, special cutting device, can save material 20%.

4. Adjustable stroke, mould replacement is simple, can be arbitrarily change the section size, suitable for a variety of specifications of the products.

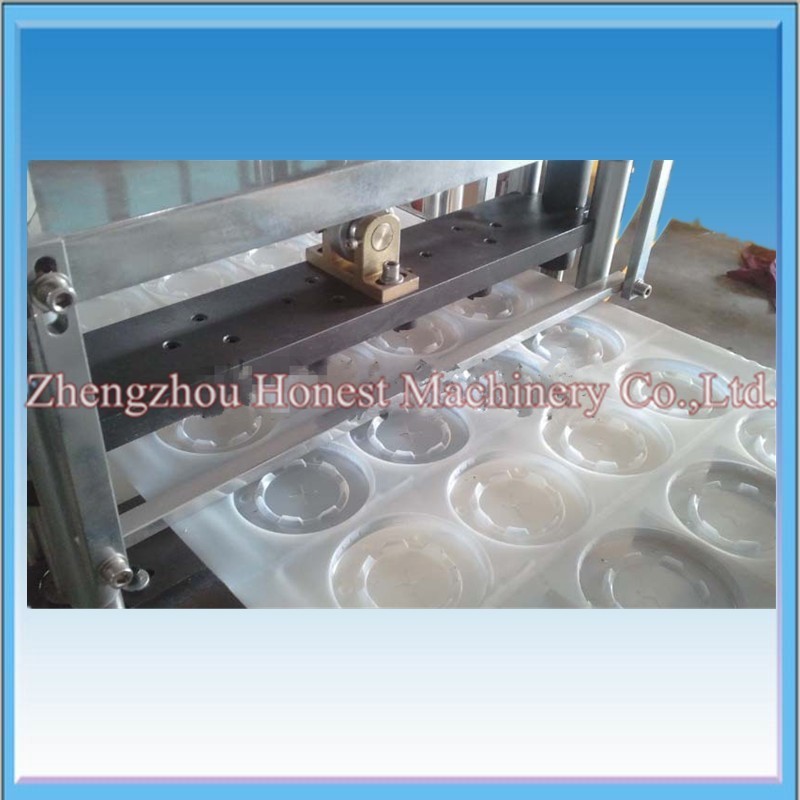

Main functions: plastic forming, punching and blanking.

Applicable objects: mainly applicable to the HIPS, PS, PVC, PET and other plastic sheet molding production of milk lid, milk tea lid, coke lid, coffee lid, cold drink lid and spoon (spoon), dish, snack tray, etc.

|

Model |

HT-450S |

|

Speed |

15-35 cycles/min |

|

Materials |

HIPS, PS, PVC, PET |

|

Total Power |

4KW |

|

Clean compressed air |

Air compressed air with 0.6-.0 Mpa Pressure |

|

Air consumption |

>3m²/Min |

|

Water chiller for moulds |

Tap water or recycle water with 60L/H consumption |

|

Max Lid width |

120mm |

|

Max Lid length |

450mm |

|

Max Lid depth |

46mm |

|

Overall dimension |

2600*1100*1700mm |

|

Weight |

2600*1100*1700mm |

|

Model |

HT-DB420 |

|

Max. Cutting speed |

8-32 times/min |

|

Optional Scope for Feeder Stroke |

40-170mm |

|

The biggest molding width |

420mm |

|

Maximum forming depth |

Max. 35mm |

|

Upper and lower heating power |

1.5kw(×2) |

|

motor power |

1.5kw |

|

Power Consumption |

three-phase four-wire 380V 50HZ(can be changed into 220V 60HZ)4.5KW |

|

pressure of supply water |

0.2MPa |

|

water consumption |

0.3m3/h(tap water or recycling water) |

|

Pump volume flow |

≥0.2m3/min |

|

Pressure |

0.4-0.7MPa |

|

Size |

1500×710×2200mm |

|

Packing Size |

1750×890×2700mm |

If you need further information, please contact us freely, we will do our best to cooperate with you.