- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Fantai

-

Voltage:

-

380V 50Hz 3phases or as your requirement

-

Dimension(L*W*H):

-

8000*1200*1300mm

-

Weight:

-

4500 kg

-

Marketing Type:

-

New Product 2022

-

Product name:

-

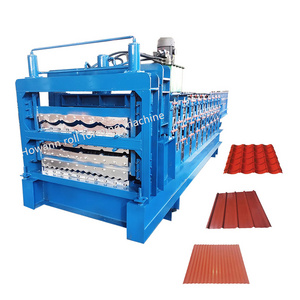

Roof Tile Roll Forming Machine

-

Usage:

-

Steel Construction

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Control system:

-

Control System

-

Cutting type:

-

Automatic Hydraulic Cutting

-

Suitable material:

-

Color Galvanized Steel Strips

-

Control box language:

-

Add Customer Request Language

-

Color of Machine:

-

Required Color

-

Frame material:

-

300 H-high Grade Steel

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Glaze Steel

-

Production Capacity:

-

10-15m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Fantai

-

Voltage:

-

380V 50Hz 3phases or as your requirement

-

Dimension(L*W*H):

-

8000*1200*1300mm

-

Weight:

-

4500 kg

-

Marketing Type:

-

New Product 2022

-

Product name:

-

Roof Tile Roll Forming Machine

-

Usage:

-

Steel Construction

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Control system:

-

Control System

-

Cutting type:

-

Automatic Hydraulic Cutting

-

Suitable material:

-

Color Galvanized Steel Strips

-

Control box language:

-

Add Customer Request Language

-

Color of Machine:

-

Required Color

-

Frame material:

-

300 H-high Grade Steel

Product Description

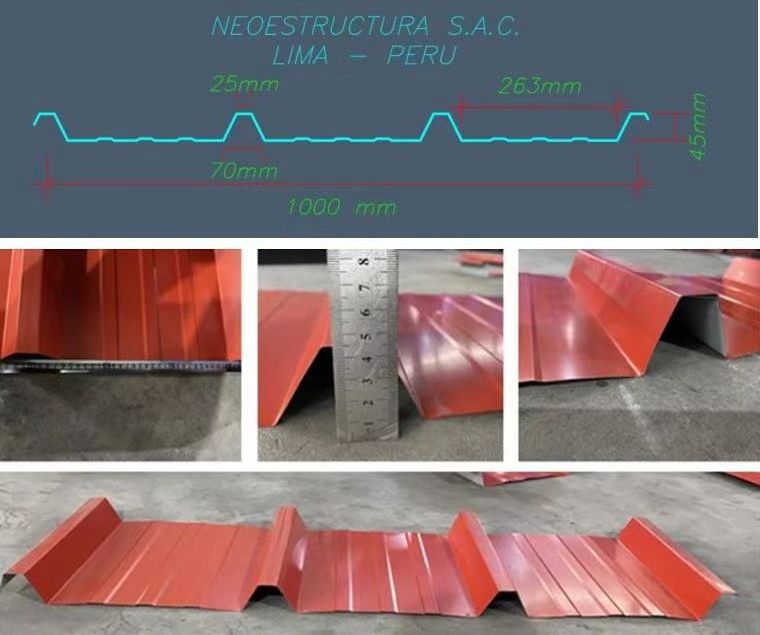

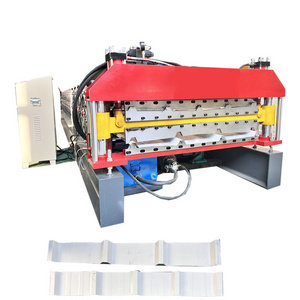

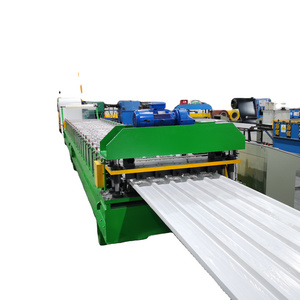

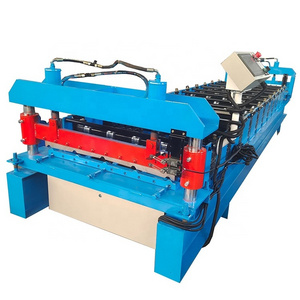

Trapezoidal Profile Roofing Sheet Making Machine

A trapezoidal sheet roll forming machine is a regular metal sheet roll former that produces metal roofing sheets or roof panels for both individual and industrial building.

This IBR metal sheet roll forming machine produces trapezoidal sheets from colour prepainted steel coils, Galvanized steel coils, aluzinc sheets, Generally, material thickness varies from 0.3 to 0.8mm, and width varies from 914mm to 1250mm. However, in some applications, material thickness can reach up to 1.5mm, like roof deck. Furthermore, in some countries or areas, people use G550 material to make full hard metal roofing sheets.

WORK FLOW Main Workflow Of TR4 Trapezoidal Sheet Roll Forming Plants

Ibr roof sheet roll forming machine

Uncoiler → Molding core → Hydraulic System → Automatic Control system → Step Formed Mechanism → Automatic Shearing Mechanism →

Products Receiving Tables

Uncoiler → Molding core → Hydraulic System → Automatic Control system → Step Formed Mechanism → Automatic Shearing Mechanism →

Products Receiving Tables

Roll Forming Machine Components:

|

Decoiler

|

1

|

set

|

|

Feeding Device With Pre-sliding Cutter

|

1

|

set

|

|

Forming Machine

|

1

|

set

|

|

Cutting Device

|

1

|

set

|

|

PLC Control Box

|

1

|

set

|

|

Hydraulic Pump Station

|

1

|

set

|

|

Production Support Table

|

1

|

set

|

Product Display

Color Steel TR4 IBR Roofing Sheet Roll Forming Machine

Trapezoida roofing sheet roll forming machine price

metal roof panel roll forming machine

metal roll forming machine

trapezoidal model making machinery

roofing sheet making machine factory

sheet forming machine

roof tile making machine factory

Specification

Color Steel TR4 IBR Roofing Sheet Roll Forming Machine

Mainly Details

Touch Screen of

Roof Sheet Roll Forming Machine

With english and Chinese for common one, if you need we customized for you, we can also do for you.

Mortor of

Roof Sheet Roll Forming Machine

Chain Drive

of Roof Sheet Roll Forming Machine

1 inch sprocket chain gear drive

Pump Station

of Roof Sheet Roll Forming Machine

4 kW air-cooled hydraulic pump station

The pressure of the hydraulic station is 10-12mpa plus No. 45 hydraulic oil. The advantage is that it can work uninterrupted for 24 hours without overheating of the hydraulic pump station.

Other design for common using

IBR Type Roll Forming Machine Sheet :

Corrugated Type

Roll Forming Machine

Sheet :

Glazed Tile Type

Roll Forming Machine

Sheet :

Why Choose Us

Easy installation of

Roll Forming Machine

Forming lines are well installed and tested before delivery, customer only connect some wire and tubes according to video and manual to start forming machines.

APPLICATION OF ROLL FORMING MACHINE

Fantai Machinery factory will design roofing machines according to your roofing profile or design, and Pre-engineered metal building advantages:

1-durable

2-withstand servere conditions.

3-low cost

4-low initial investment and low maintain cost

5-environment friendly

6-all the material can be recycled

7-flexible design

8-can relocate

9-install time considerably reduced

Operate easily , work automatically with PLC controller control.

Decoiler- forming-cut – run out

Application of Trapezoidal Roof Roll Forming Machine

This IBR profile

Roll Forming Machine

is designed for commercial and industrial roofing; which is suitable for low pitch roofing as well as curved roofing.Sheets with higher ribs and bold ribs, making exceptionally attractive and high-performance roofing and cladding product for various Light Steel structure construction, civil construction, and mansions Building.

Recommend Products

Company

Henan Fantai Machinery Co., Ltd.

Henan Fantai Machinery Co., Ltd. is a manufacturer of automatic production lines for color steel tile forming equipment. For many years, it has been engaged in the production of roof panels and wall panel color steel tile equipment for steel structures. With production equipment and development and design engineers, its products include the original roof panel and wall panel color steel tile equipment.

So far, dozens of series of color steel tile equipment production lines have been developed to meet the needs of major customers. Our product series include: sandwich composite panel production line, C/Z steel machine, glazed tile forming machine, roof panel forming machine, wall panel forming machine, double-layer forming machine, corner forming machine, windproof and dust suppression net forming machine, high-speed Guardrail forming machine, floor deck forming machine, several-shaped steel forming machine, W-shaped steel belt forming machine, carriage plate forming machine, roof tile forming machine, advertising decorative gusset forming machine, rolling door forming machine, bottom plate forming machine, bending and shearing board Strip forming machine, eaves panel forming machine, arching forming machine, supporting auxiliary equipment, agricultural greenhouse equipment, environmental protection dust removal and purification equipment, etc.

FAQ

1. Does one machine can only produce one style panel profile?

Not exactly.For wider and double layer Roll Forming Machine . It can produce more than 6 kinds of panels.

2. Do you have after sales support?

Yes, we are happy to give advice and we also have skilled technicians available across the world.We need your machines running in order to keep your business running.

4. What can you do if the Roll Forming Machine broken?

Our machine's warranty period is 12 months,if the broken parts can't repair,we can send the new parts replace the broken parts freely,but you need pay the express cost yourself.if after warranty period,we can through negotiation to solve the problems,and we supply the technical support for the whole life of the equipment.

5. Can you be responsible for transport?

Yes,please tell me the destination port or address.we have rich experience in transport.

Not exactly.For wider and double layer Roll Forming Machine . It can produce more than 6 kinds of panels.

2. Do you have after sales support?

Yes, we are happy to give advice and we also have skilled technicians available across the world.We need your machines running in order to keep your business running.

3.

How long the

Roll Forming Machine

could be made?

Normally speaking, roof panel making machine could be made without 25 working days. If you need machines in a hurry, we can make it for you less than a month.

4. What can you do if the Roll Forming Machine broken?

Our machine's warranty period is 12 months,if the broken parts can't repair,we can send the new parts replace the broken parts freely,but you need pay the express cost yourself.if after warranty period,we can through negotiation to solve the problems,and we supply the technical support for the whole life of the equipment.

5. Can you be responsible for transport?

Yes,please tell me the destination port or address.we have rich experience in transport.

Hot Searches