- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Bosun

-

Model Number:

-

BA

-

Use:

-

polishing, grinding and blasting

-

Product name:

-

brown aluminum oxide

-

packaging detail::

-

25kg PVC bag+1000kg big bag

-

color::

-

Brown grain or powder

-

Al2O3::

-

50%-97%

-

Application:

-

Abrasive Refractory Industry

-

Shape:

-

Round

-

Certificate:

-

ISO9001

-

Sample:

-

Sample Provided

-

Payment Terms:

-

T/T

-

Grade:

-

Professional

Quick Details

-

Type:

-

blasting media

-

Abrasive Grain Sizes:

-

F15~F320

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Bosun

-

Model Number:

-

BA

-

Use:

-

polishing, grinding and blasting

-

Product name:

-

brown aluminum oxide

-

packaging detail::

-

25kg PVC bag+1000kg big bag

-

color::

-

Brown grain or powder

-

Al2O3::

-

50%-97%

-

Application:

-

Abrasive Refractory Industry

-

Shape:

-

Round

-

Certificate:

-

ISO9001

-

Sample:

-

Sample Provided

-

Payment Terms:

-

T/T

-

Grade:

-

Professional

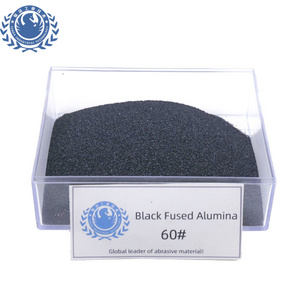

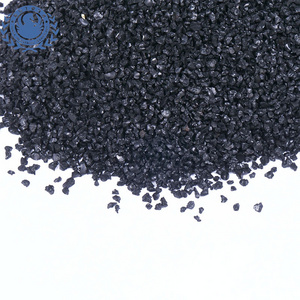

Brown aluminium oxide/brown fused alumina

Brown aluminium oxide is fused and crystallized under high temperature from a mixture of bauxite and other and other raw materials. It is characterized by its high hardness,good toughness and shape in size. Abrasives tools made of it are suitable for grinding metals of high-tensile strength such as: carbon steel,general-purpose alloy steel,annealed malleable iron and hard broze,etc.It also can be used as refractory materials.

character

1 AL2O3 95% SIO2 1.5% ;

2 Fe2O3 0.3% TIO2 3.0% ;

3 Hardness(mohs) 9 ;

4 Ture density 3.9 ;

5 Magnetic material content 0.050%.

Physical and chemical analysis for brown fused alumina:

|

Purpose |

Specification |

Chemical composition(%) |

Magnetic material content(%) |

||||||||||

|

Al2O3 |

Fe2O3 |

SiO2 |

TiO2 |

||||||||||

|

Abrasive Grade |

F |

4# — 80# |

95.0 Min |

0.3 Max |

1.5 Max |

3.0 Max |

0.05 Max |

||||||

|

90# — 150# |

94.0 Min |

0.03 Max |

|||||||||||

|

180# — 240# |

93.0 Min |

0.3 Max |

1.5 Max |

3.5 Max |

0.02 Max |

||||||||

|

P |

8# — 80# |

95.0 Min |

0.2 Max |

1.2 Max |

3.0 Max |

0.05 Max |

|||||||

|

100# — 150# |

94.0 Min |

0.03 Max |

|||||||||||

|

180# — 220# |

93.0 Min |

0.3 Max |

1.5 Max |

3.5 Max |

0.02 Max |

||||||||

|

F230-F1200 |

92.5 Min |

0.5 Max |

1.8 Max |

4.0 Max |

— |

||||||||

Application

1. it are suitable for grinding high-speed,high carbon steel

2.high-grade refractory materials

3.abrasives tool

4.grinding and polishing

5.ceramics

6.LED

7.sandblasting

8.aviation

25kg /bag, 1000kgs/40 bags/ pallet.

20-26 metric tons/ container.

Package could made according to customer's request.

1. Free samples : we can supply 200gs steel shot ball samples for free.

2. Direct manufacturer to product steel shot ball.

3. High quality steel shot s390: our steel shot ball have passed the ISO quality.

4. After sales service : we can supply technical service for free when you using our steel shot ball.

The company sets up a dedicated after-sales service department which is mainly responsible for product pre-sales and after-sales technical service,including application consulting, customer opinion survey, customer complaint management ang the like of metal abrasive cast steel shots, cast steel shots, steel cut wire shots, stainless steel shots and shot casting machinery for cleaingblast shot and intensifying sprayed shots.

We hope to achieve the purposes of providing best using method,achieving optimum working efficincy, realizing the maximum productivty, and consuming the lowest production cost through our commom efforts.