- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 240*115*53 mm, 220*110*50 mm, Customized

-

Place of Origin:

-

China

-

Brand Name:

-

Hongfa

-

Voltage:

-

Customized, 220/380V/Customized

-

Marketing Type:

-

Other

-

Weight (KG):

-

2000 kg

-

Vibration Frequency:

-

4600r/M

-

Molding Cycle:

-

15-20s

-

Pallet size:

-

680*530mm

-

Rated Pressure:

-

16MPa

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine, Other, Brick Making Machine

-

Brick Raw Material:

-

Cement

-

Production Capacity (Pieces/8 hours):

-

Hollow Blocking: 3456-4320pcs / 8 hours

-

Brick size:

-

400*100*200 mm, 240*115*53 mm, 220*110*50 mm, Customized

-

Place of Origin:

-

China

-

Brand Name:

-

Hongfa

-

Voltage:

-

Customized, 220/380V/Customized

-

Marketing Type:

-

Other

-

Weight (KG):

-

2000 kg

-

Vibration Frequency:

-

4600r/M

-

Molding Cycle:

-

15-20s

-

Pallet size:

-

680*530mm

-

Rated Pressure:

-

16MPa

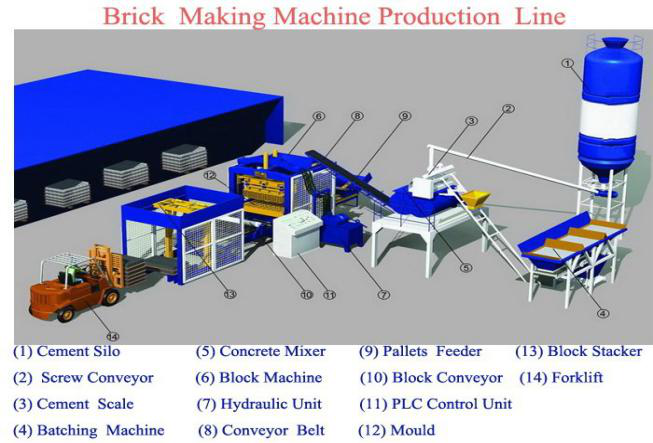

QTF3-20 Automatic Cement Concrete Brick / Block Making Machine

Brief intruduction

A.The machine can serve several purposes and can produce pavement bricks, riverside bricks, revetment bricks ,square bricks ,grassed bricks and so on with different moulds.

B.Low frequency in feeding material, high frequency vibration. Platform vibrating works together with mould, So that the concrete can be fully fluidified and exhausted in two or three seconds to reach the high density.

C.The advanced technique of hydraulic-controlled proportion can handle the oil press and amount of the system freely,therefore ,different materials can be able to produce the high quality products.

D.All the procedures are operated by PLC and equipment with out and in date device to realize person-machine conversation. Control system also including the advanced safe logical system and fault diagnosis system.

Control system

PLC intelligent control. Man-machine interface, control system equipped with complete logic control, production program, malfunction diagnosis system and remote control function. So it doesn't need a professional person but only need a simple trained one to the operator.

Product scope: It produces various bricks/blocks including color-face bricks (layered material feeding),through-body tiles,lock linkage blocks, road curb bricks, hydraulic blocks,hollow blocks, perforated bricks, and standard bricks etc.

Productivity(can change moulds):

| Block | Size | Cycle time | Qty/mould | Qty/hour | Qty/ 8 Hours |

| Hollow Block | 400*200*200mm | 20-25s | 3pcs | 432-540 pcs | 3456-4320 pcs |

| Solid Block | 240*115*53 mm | 18-23s | 14pcs | 2200-2800 pcs | 17600-22400 pcs |

| Color Brick | 220*110*50 mm | 20-25s | 8pcs | 1150-1440 pcs | 9220-11500 pcs |

Note: The forming cycle is 18-25 seconds per pallet,above capacity we counted by average 20 seconds per pallet.

Technical Parameter:

|

Main vibration form |

Platform vibration |

|

Cycle Time |

20 seconds |

|

Overall weight |

2000kg |

|

Motors Power |

14.25KW |

|

Pallet Size |

680*530(mm) |

a) full automatic brick plant is a compact oil hydraulic machine according to the standard of international. Many parts from abroad which ensure the quality of the machine and take fro the power.

b) The vibration system contains platform vibration and mould vibration so the products are very close grained and produced quickly.

c) The novel feeding system gives material exactly and average and assures the products having a high density.

Control system

a) PLC intelligent control. human-computer interface, control system equipped with complete logic control, production program, malfunction diagnosis system and remote control function. So it doesn't need a professional person but only need a simple trainning to the operator.

b) Product scope: It produces various bricks/blocks including color-face bricks (layered material feeding), through-body tiles,lock linkage blocks, road curb bricks, hydraulic blocks, hollow blocks, perforated bricks and standard bricks etc.

A leader developer& Manufacturer of Construction Material Machinery.

Main business Range & Products:

Lightweight Panel Production Line, AAC Block Production Line, Full Automatic Concrete Block Production Line, Artificial Quartz Plate Production Line, Concrete Pipe Machine, Concrete Tile Machine, Concrete pipe machine, Bidirectional Hydraulic Brick Maker, Mining Machinery, Concrete Batching plant, Stereo Parking Equipment, etc.

Main Products :

concrete block machine,

EPS Light weight wall panel machine

,

AAC block production line

, concrete batching plant,

Artificial quartz stone plate production line

,

Culcium Silicate Board Production Line

, concrete terrazzo tile machine and concrete pipe machine. etc.

Automatic Block Making:

QT12-15D QT12-15 QT10-15D QT10-15 QT9-15 QT8-15D

QT8-15B QT6-15D QT6-15C QT6-15B QT4-15D QT4-15C

QT4-15B QT4-20C QTJ4-25

Semi-automatic:

QTJ4-35B2 QTJ4-40B2

Semi-automatic egg-laying machine:

QTY4-30 QMJ4-45 QTJ2-45 JMQ-6A

Color Paver Color tile forming machine:

QT3-20 SMY8-150

HF-800 pipe-making machine HF-2000 pipe-making machine

Concrete Mixing Plant:

HZS25 HZS35 HZS50 HZS60 HZS series

AAC Block production line : 50000~500000m³/Year

More than 30 years experience. 1500 employee (50+engineers)

2) Total 4 factories with 440,000M2 and annual sell above USD100 Million .

3) 10,000 customers and fulfillment to over 120 countries.

4) Continuous service and logistics system.

5) High quality products and competitive price.We hope we can cooperate with each other and establish a win-win business relationship.

We will provide the following service for you:

1.Analyzing:Plant size, budget, automatic degree, local condition....analyzing all of your requirements

2. We offer technical support until the workers know how to operate.

3. The operating instruction will go to the customers with the equipment. Technology data and relative files for production line

4.We provide lifelong guidance . Visiting clients in regular times.

Exhibitions & cooperations

Hongfa, as a top brand enterprise in China, our products are also exported to Russia, Brazil, Thailand, Indonesia, Vietnam,Angola, Bangladesh, India, Australia, Sudan, etc., 132 countries and regions, deeply welcomed by clients from all around the world.