- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZOMAGTC

-

Voltage:

-

220V /380V 3P

-

Dimension(L*W*H):

-

2400*1500*2100mm

-

Weight:

-

1200 kg

-

Product name:

-

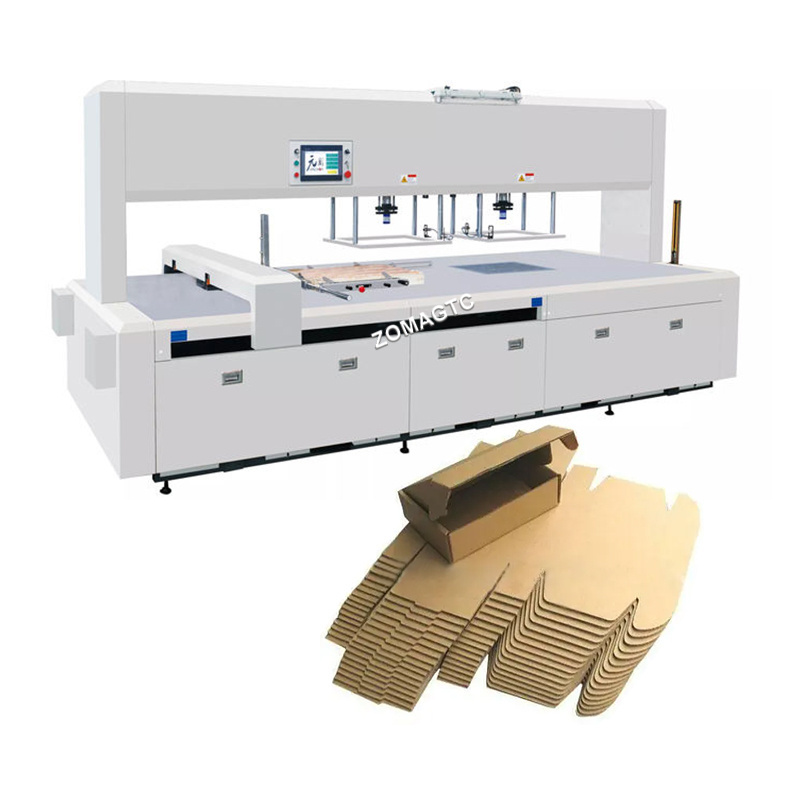

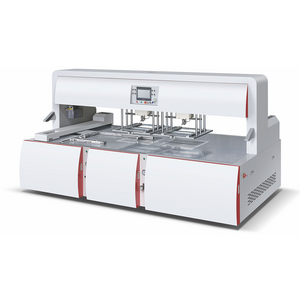

Automatic Cardboard Blanking Stripping Blank Separator Machine

-

Hydraulic pressure:

-

Max. Pressure 4000KG

-

Speed:

-

Blanking Speed 500-800 times/hour

-

Precision:

-

Positioning: 0.05 mm/Repeating: 0.02 mm

-

Max. Blanking Size:

-

340x340mm

-

Min.Stripping Size:

-

30x30mm

-

Operation System:

-

PLC controlled

-

Max. Paper Size:

-

720*520mm

-

Machine Power:

-

3KW

-

Machine size:

-

2400*1500*2100mm

Quick Details

-

Type:

-

cnc cardboard cutting machine

-

Production Capacity:

-

500-800 times/hour

-

Max. workable width:

-

520mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZOMAGTC

-

Voltage:

-

220V /380V 3P

-

Dimension(L*W*H):

-

2400*1500*2100mm

-

Weight:

-

1200 kg

-

Product name:

-

Automatic Cardboard Blanking Stripping Blank Separator Machine

-

Hydraulic pressure:

-

Max. Pressure 4000KG

-

Speed:

-

Blanking Speed 500-800 times/hour

-

Precision:

-

Positioning: 0.05 mm/Repeating: 0.02 mm

-

Max. Blanking Size:

-

340x340mm

-

Min.Stripping Size:

-

30x30mm

-

Operation System:

-

PLC controlled

-

Max. Paper Size:

-

720*520mm

-

Machine Power:

-

3KW

-

Machine size:

-

2400*1500*2100mm

Products Description

Automatic Blank Cnc Cardboard Cutting Machine Single Head Blanking Waste Paper Recycling Cardboard Waste Stripping Machine

|

Model

|

ZM-QF720

|

ZM-QF1080B

|

ZM-QF1080C

|

||

|

Hydraulic pressure

|

Max. Pressure 4000KG

|

7Mpa

|

7Mpa

|

||

|

Speed

|

500-800 times/hour

|

|

500-800 times/hour

|

||

|

Precision

|

Positioning: 0.05 mm

|

|

Positioning: 0.05 mm

|

||

|

|

Repeating: 0.02 mm

|

Repeating: 0.02 mm

|

Repeating: 0.02 mm

|

||

|

Max. Blanking Size

|

340*340mm

|

520×380mm

|

520×380mm

|

||

|

Min.Stripping Size

|

30*30mm

|

180x180mm(1080 format);

30x30mm(540format)

|

180x180mm(1080format);

30x30mm(540format)

|

||

|

Max. Blanking Thickness

|

Paper 120g- 1800g

|

Paper 120g- 1800g

|

Paper 120g- 1800g

|

||

|

|

Thickness 60mm-95mm (50-200sheets)

|

|

Thickness 60mm-95mm

(50-200sheets) |

||

|

Operation System

|

PLC controlled

|

PLC controlled

|

PLC controlled

|

||

|

Max. Paper Size

|

720*520mm

|

1080x780mm

|

1080x780mm

|

||

|

Min. Paper Size

|

540*410mm

|

540x410mm

|

540x410mm

|

||

|

Machine power

|

3kw

|

4.2KW

|

6.7KW

|

||

|

Machine Weight

|

1500KG

|

2000kg

|

3700kg

|

||

|

Machine Size

|

2400*1500*2100mm

|

3300×1750×2000mm

|

4350×1800×2000mm

|

||

The automatic blanking and stripping machine is mainly used for cleaning waste after die-cutting of various tags, cigarette packs,packs, food packaging, cosmetic packaging boxes, cartons, etc. in printing plants, and is suitable for die-cutting in printing, packaging and decoration, and plastic industries production of various ordinary cardboard, plastic sheets, and leather products. It has the characteristics of compact structure, excellent manufacture, high pressure, high precision, fast speed, convenient use, safe and reliable operation, which greatly reduces the labor intensity of users and reduces labor costs.

(1). The fuselage is welded with high-quality materials. The fuselage is heavy and high-strength. It is processed with high precision by the machining center, which improves the assembly accuracy of the equipment and prolongs its service life.

(2). The cross platform, the stripping head is fixed, the cross platform is driven by subdivided micro-step servo motor with strong power and no maintenance, the motion transmission is completed by precision ball screw and linear guide rail, the product moves along two axes, and working area is limited by software and hardware positioning switches. The cross platform is more suitable for multi-imposition and separate blanking products.

(3). Honeycomb thimble-type waste stripping structure, the honeycomb panels adopt a unique arrangement, the distance between the honeycomb holes is only 2.7mm, and ∅10mm thimbles are used, which can be assembled freely according to the shape of the waste stripping products. The thimble arrangement is close to the shape of the product, and the thimble The addition of beef tendon rubber heads is more conducive to product cleaning and waste reduction.

(4). The closed body cover and safety light curtain design enhance the safety of equipment operation; the operation height is arranged reasonably and easy to use.

(5). The operating platform is made of 10mm thick chrome-plated steel plate, which is finished by the machining center, which makes the stripping products move more smoothly on the platform and prolongs the service life of the products.

Contact us

Company: Zhengzhou ZOMAGTC Co. Ltd

Contact: Ms. Ellen

Wechat/Whatsapp/Viber: +8619138001306

Email: ellenzhang@superelec.cn

Recommend products

Hot Searches