- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

47*44*62cm

-

Weight (KG):

-

25

-

Model Number:

-

THD601

-

Size:

-

47*44*62cm

-

Input voltage:

-

110/220VAC

-

Hopper volume:

-

45L

-

Output air pressure:

-

0-0.5MPa

-

Residual water in compressed air:

-

max1.3gNm(dew point 7℃)

-

Max Output voltage:

-

0-100KV

-

Input air pressure:

-

0-0.6MPa

-

Residual oil in compressed air:

-

max0.01g

Quick Details

-

Machine Type:

-

powder coating plant, Painting Equipment, Coating Equipment

-

Core Components:

-

spray gun

-

Place of Origin:

-

China

-

Dimension(L*W*H):

-

47*44*62cm

-

Weight (KG):

-

25

-

Model Number:

-

THD601

-

Size:

-

47*44*62cm

-

Input voltage:

-

110/220VAC

-

Hopper volume:

-

45L

-

Output air pressure:

-

0-0.5MPa

-

Residual water in compressed air:

-

max1.3gNm(dew point 7℃)

-

Max Output voltage:

-

0-100KV

-

Input air pressure:

-

0-0.6MPa

-

Residual oil in compressed air:

-

max0.01g

Products exhibition

Products Description

The spray equipment uses an automatic current feedback circuit and adds a pulse control circuit. The gas control part adopts two-stage gas source filtration, voltage regulation and air pressure adjustment, all designed as preset adjustments. The powder output is more uniform, the atomization is better, and the dead angle is much better.

Use the digital panel forwarding key. It can change the pulse and normal function, and voltage current display function. With a very high powdering rate and the best coating quality.

Use the digital panel forwarding key. It can change the pulse and normal function, and voltage current display function. With a very high powdering rate and the best coating quality.

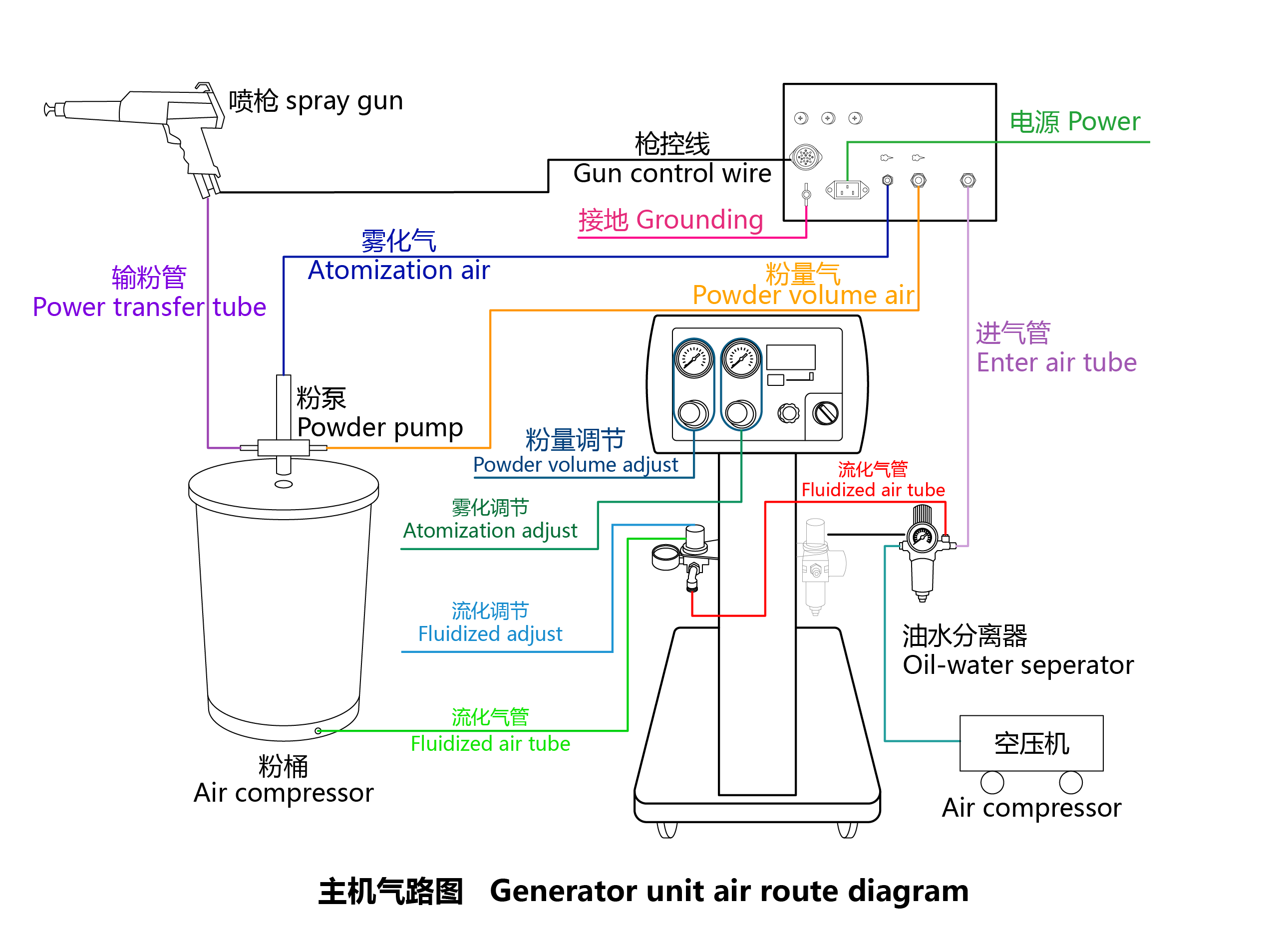

Product wiring diagram

Commisioning:

After long transportation, the machine might bear strong shock, so before using the machine, must check machine structure is fasten or not, all parts are still there, according to the assembly drawing in operation manual, to connect the whole machine, then check the power supply meets the requirement of the machine or not, check the special ground wire is correct or not,

then can power on for commissioning.

Commissioning method: connect power supply plug, ground connecting well, open the machine power switch, power supply light up, then press gun trigger switch, then twist high voltage adjustment button at clockwise direction. If voltage increase, it means high voltage electrostatic is generated, machine starts working.

then can power on for commissioning.

Commissioning method: connect power supply plug, ground connecting well, open the machine power switch, power supply light up, then press gun trigger switch, then twist high voltage adjustment button at clockwise direction. If voltage increase, it means high voltage electrostatic is generated, machine starts working.

Feature

1. The workplace can be painted at room temperature

2. High powder utilization rate, up to 95%

3. The coating film is thin and uniform, smooth without sag

4. On the sharp edges and rough surface of the workpiece, a continuous and smooth coating can be formed

5. Easy to realize industrial line production

6.It is more environmentally friendly than spray-paint, but the fireproof and explosion-proof grades are sightly lower.

7. The social and economic benefits are significant , the cost is 20`30% lower than the solvent process, and the batch production cycle is shortened by 20 days.

2. High powder utilization rate, up to 95%

3. The coating film is thin and uniform, smooth without sag

4. On the sharp edges and rough surface of the workpiece, a continuous and smooth coating can be formed

5. Easy to realize industrial line production

6.It is more environmentally friendly than spray-paint, but the fireproof and explosion-proof grades are sightly lower.

7. The social and economic benefits are significant , the cost is 20`30% lower than the solvent process, and the batch production cycle is shortened by 20 days.

Use guide

1. High voltage controller power line, has special earth wire, should be connected with earth wire of electricity network socket. Must NOT use power zero line instead. Earth wire on the power supply socket and machine body must keep ground connection well, otherwise it will cause high voltage electric shock, and burn out machine or reduce the machine life time, or dangerous for personal security.

2.

All metal conductive items on working field must ground connecting(including working piece hanging

tool, fire extinguish equipment, electrical cabinet etc.)

tool, fire extinguish equipment, electrical cabinet etc.)

3.

Built-in spray gun should keep dry, should clean machine body and powder tube after use every time,

operator should check gun regularly, if find gun has electricity leakage or insulation, should repair or replace, must NOT use it.

operator should check gun regularly, if find gun has electricity leakage or insulation, should repair or replace, must NOT use it.

Contact

Cici Lei

Whatsapp/wechat/phone:

+8618716717704

Hot Searches