- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HSM

-

Dimension(L*W*H):

-

4210*1630*1260mm

-

Weight:

-

9.5 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

roll crusher diagram

-

Company type:

-

Manufacture

-

Cost:

-

Low cost

-

Motor:

-

Made in china or according to your need

-

Color:

-

As requested

-

Material-out size(mm):

-

0-2mm, can be adjusted

-

Aftersale-service:

-

Lifetime warranty

-

Installation:

-

Under engineer's guide

Quick Details

-

Application:

-

cement /chemcial industry /electric industry, Stone, ore, rock, coal, etc

-

Capacity(t/h):

-

10-40t/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HSM

-

Dimension(L*W*H):

-

4210*1630*1260mm

-

Weight:

-

9.5 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

roll crusher diagram

-

Company type:

-

Manufacture

-

Cost:

-

Low cost

-

Motor:

-

Made in china or according to your need

-

Color:

-

As requested

-

Material-out size(mm):

-

0-2mm, can be adjusted

-

Aftersale-service:

-

Lifetime warranty

-

Installation:

-

Under engineer's guide

Products Description

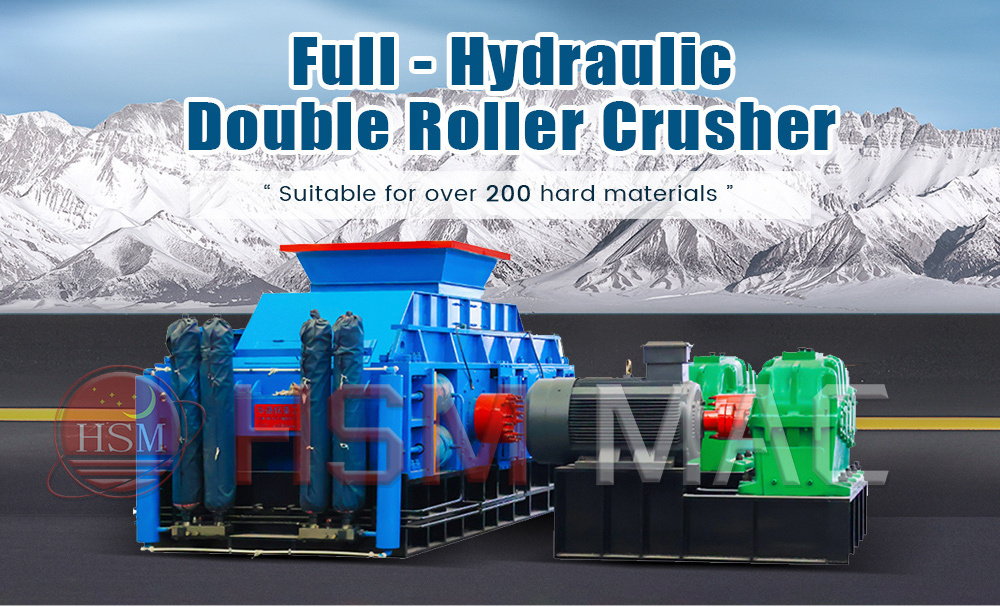

The hydraulic double roller crusher is mainly used for fine crushing operations with particle size requirements of less than 80mm and finished products of 50-20mm. Applicable material: River pebble, Calcite, quartzite, marble, cobble, bentonite, iron ore, bluestone, mountain stone, water slag, limestone, weathered sand, Diabase, granite, basalt. Highway, railway, high-rise buildings, municipal, hydropower dam construction, concrete mixing station, sand and stone field, etc

|

Model

|

Feeding size (mm)

|

Discharging size (mm)

|

Capacity (t/h)

|

Motor power (kw)

|

Weight (t)

|

Dimension (mm)

|

|

2PG400×250

|

<35

|

≤2-8

|

2-10

|

2×5.5

|

1.3

|

2110×870×810

|

|

2PG610×400

|

<65

|

≤2-20

|

5-20

|

2×15

|

3.9

|

3510×1420×1030

|

|

2PG750×500

|

<75

|

≤2-25

|

10-40

|

2×18.5

|

9.5

|

4210×1630×1260

|

|

2PG800×600

|

<80

|

≤2-25

|

12-45

|

2×22

|

10.8

|

4505×1780×1320

|

|

2PG1000×700

|

<100

|

≤3-30

|

20-65

|

2×30

|

14.9

|

5310×2175×1595

|

|

2PG1200×800

|

<120

|

≤3-35

|

35-80

|

2×37

|

25.5

|

6290×2270×1870

|

|

2PG1500×800

|

<130

|

≤3-45

|

50-120

|

2×75

|

33.7

|

7460×2410×2290

|

|

2PG1600×1000

|

<150

|

≤3-50

|

60-140

|

2×90

|

41.2

|

8220×2680×2475

|

Working Principle

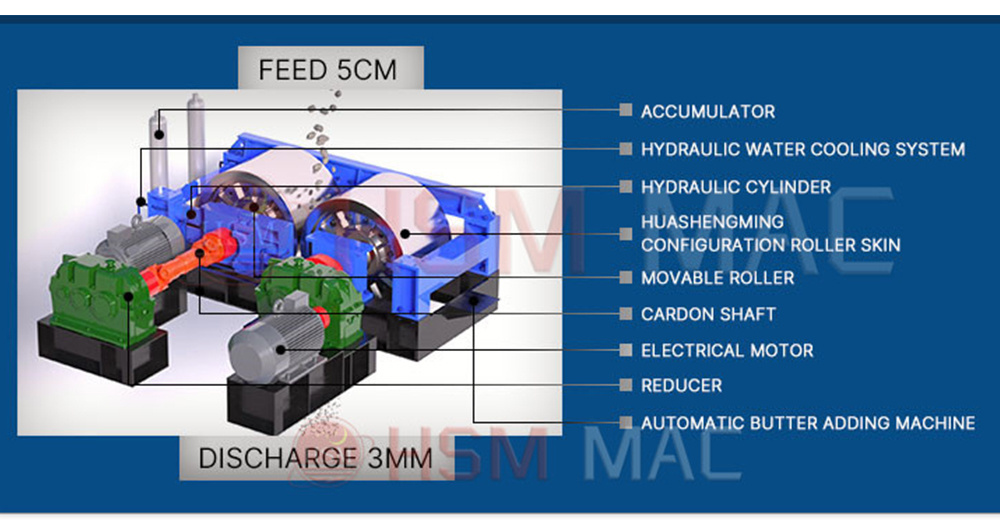

1. The interior is equipped with a dustproof plate with good sealing performance, avoiding the splashing of small materials aftercrushing, resulting in less dust and low working noise.

2. This machine is equipped with safety protection settings. When an unexpected metal iron piece enters the crushing chamber, the protection device is activated, and the equipment operates normally when the iron piece leaks out.

3. The abrasive gap of this machine can be adjusted before 1mm~20mm, and the size of crushed particles can be controlled after adjustment according to the crushing requirements.

3. The abrasive gap of this machine can be adjusted before 1mm~20mm, and the size of crushed particles can be controlled after adjustment according to the crushing requirements.

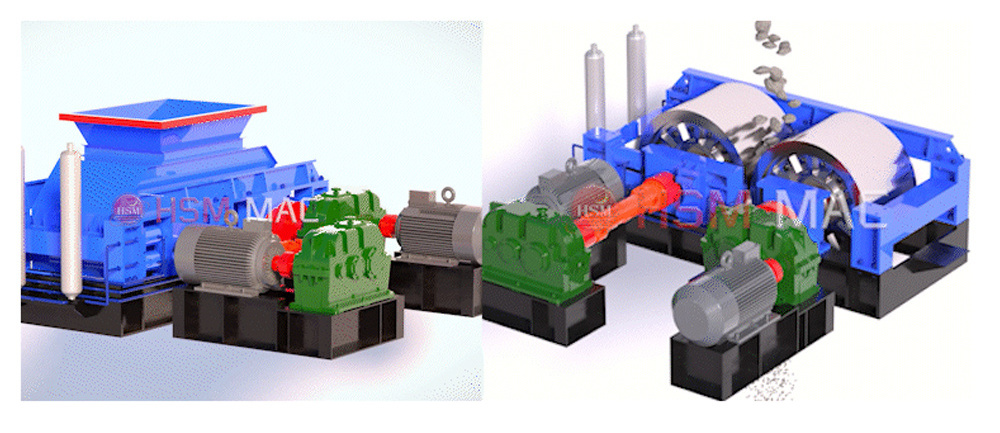

The hydraulic roller crusher is a kind of machine which is extended by the spring roller crusher. The advantage of hydraulic

structure is that it can control the pressure between two reliefs accurately. Long-term continuous operation can still guarantee the crushing pressure between two rollers. Therefore, the equipment of roller crusher in the grinding system can give full play to the production capacity of the grinding equipment. Generally, the output can be increased by 30%~40%, and the total energy consumption can be reduced by 20%-30%.

structure is that it can control the pressure between two reliefs accurately. Long-term continuous operation can still guarantee the crushing pressure between two rollers. Therefore, the equipment of roller crusher in the grinding system can give full play to the production capacity of the grinding equipment. Generally, the output can be increased by 30%~40%, and the total energy consumption can be reduced by 20%-30%.

We will supply the wear parts with factory price . You can buy from our factory

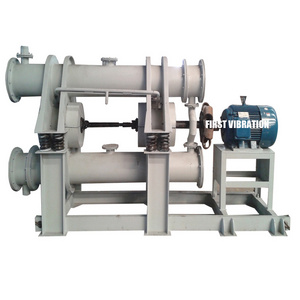

The main structure of the wheel gearing is composed of fixed roll, movable roll, drive shaft, machine box, chassis, cover piece,and long gear cover. The motive power of the machine comes from the V-belt pulley of the electro motor, and a pair of middle reduction gear will make the fixed roll rotate, and then a pair of long gear drive on the other side of the fixed roll will drive the movable roll, and the two rolls perform relative movement to squeeze the materials.

Details Images

If you want to learn more product information, please click here to contact us!!!

Product Display

Customer Photos

Hot Searches