Loading capacity: 12t

Max coil width: 1250mm

Coil inner diameter: 480-610mm

Hydraulic mandrel expansion

Electric motor mandrel drive

Hydraulic motor power: 5.5kw

Drive motor power: 7.5kw

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.8-1.2 mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZHONGTUO

-

Voltage:

-

220V-3P-50HZ

-

Weight:

-

10000 kg

-

Feeding width:

-

Other

-

Marketing Type:

-

New design 2023

-

Product name:

-

metal decking roll forming machine

-

Control system:

-

Delta

-

Thickness:

-

0.8-1.2 mm

-

Shaft material:

-

95 mm

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Color:

-

Custimized

-

Roller stations:

-

28 roller stations

-

Control box language:

-

Add Customer Request Language

-

Decoiler:

-

Manual or hydraulic decoiler

-

Main frame:

-

400 H Steel Welding

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

4 m/min

-

Rolling thinckness:

-

0.8-1.2 mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZHONGTUO

-

Voltage:

-

220V-3P-50HZ

-

Weight:

-

10000 kg

-

Feeding width:

-

Other

-

Marketing Type:

-

New design 2023

-

Product name:

-

metal decking roll forming machine

-

Control system:

-

Delta

-

Thickness:

-

0.8-1.2 mm

-

Shaft material:

-

95 mm

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Color:

-

Custimized

-

Roller stations:

-

28 roller stations

-

Control box language:

-

Add Customer Request Language

-

Decoiler:

-

Manual or hydraulic decoiler

-

Main frame:

-

400 H Steel Welding

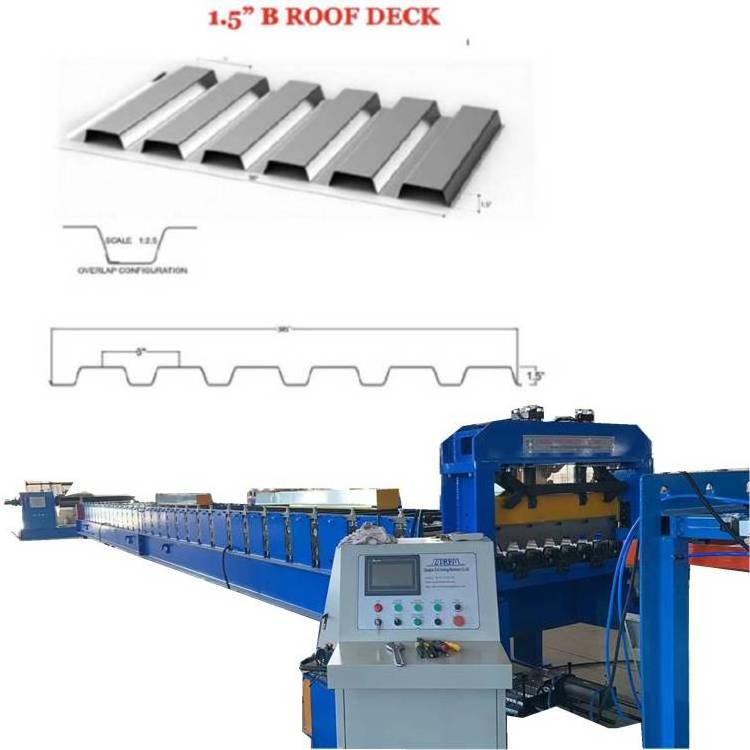

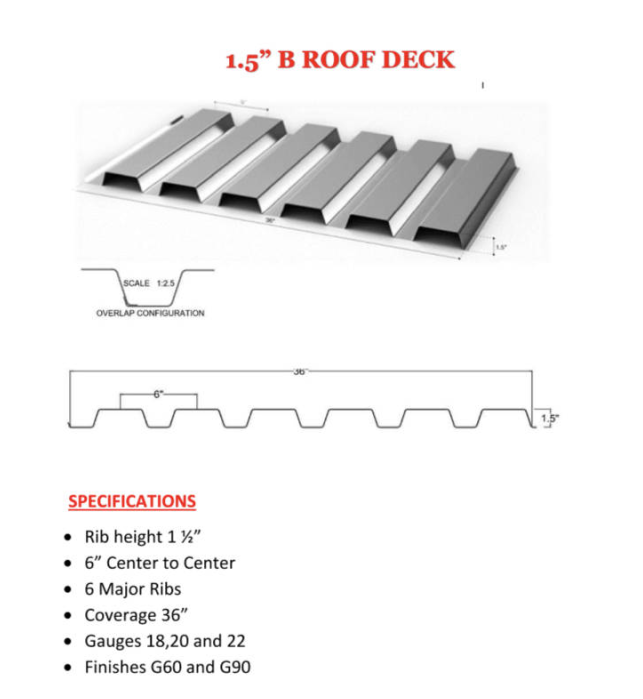

Heavy Duty America Standard Roof Decking Floor Deck Sheet Roll Forming Machine

Deck sheet roll forming machine is one of our main roll forming machines, we made many machines for the North American countries, such as the America, Canada, Mexico. Especially for the America, we already sent many floor decking machines to there, we have customer from New York, Florida, Texas, California as so on.

Design Idea:

Logo press:

add the logo press for customer, the logo will be pressed when the share part do the shearing job.

Good shearing:

shearing system adopt double oil cylinder 7.5 kw motor, more stable than single oil cylinder and can guarantee the cutter can cut 1.5 mm thickness material easily.

Stable-transmission:

2 inches double chain with chain tensors.

Profile drawing for reference:

We made many floor decking machines for the North American countries, such as the America,

Canada, Mexico. Especially for the America, we already sent many floor decking machines to there, we have customer from New York,Florida, Texas, California as so on.

The floor decking machine America use are almost same and standard, 1.5 B type is one they normally used. and the material thickness they used are Gauges 16 18 20 22 as so on. Most of the metal floor decking panel are 36” effective width and 48” input material width.

Canada, Mexico. Especially for the America, we already sent many floor decking machines to there, we have customer from New York,Florida, Texas, California as so on.

The floor decking machine America use are almost same and standard, 1.5 B type is one they normally used. and the material thickness they used are Gauges 16 18 20 22 as so on. Most of the metal floor decking panel are 36” effective width and 48” input material width.

We sell many floor deck roll forming machines to American,if interested in just contact us for suggest or see our machines in American local.

Here is the photos that our engineer install floor deck roll forming machine in our America customer's factory

Processing Flow

Decoiler-feeding material-roll forming-cutting-receiving the product

|

1.5" B 3" B concrete roof deck floor roll forming machine

|

|

|

|

Raw material

|

Galvanized coils yield strength till 550 Mpa

|

|

|

|

Material thickness:16-22gauge( 0.8-1.5 mm)

|

|

|

Machine frame

|

400 H beam steel welded

|

|

|

Roller fixer

|

Middle plate (thickness 20mm)

|

|

|

Material of rollers

|

Gcr15 quenching treat HRC58-60

|

|

|

Forming stations

|

28 roller stations

|

|

|

Diameter of shafts

|

φ 95 mm

|

|

|

Material of shafts

|

45# steel precision-machined

|

|

|

Forming speed

|

0-15 m per minute

|

|

|

Voltage

|

480 v 60 hz 3 phase or as request

|

|

|

Transmission way

|

Gear and 2 inches double chain with chain tensors

|

|

|

Drive motor

|

Power:18.5 kw x 2 sets

installation: inside the machine |

|

|

Cutting blade material

|

Cr12Mov quenched treatment to improve hardness

|

|

|

Cutting type

|

Hydraulic cutting

|

|

|

Dimension of the machine

|

15000 х 1850 х 1500 mm

|

|

|

Weight

|

about 15.5 t

|

|

12 tons hydraulic decoiler with loading car

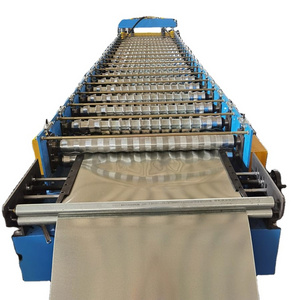

Feeding device

1. Rubber rollers protect raw material surface

2. With handwheels easy adjust for feeding different thickness raw material.

2. With handwheels easy adjust for feeding different thickness raw material.

3.The feeding part is mold iron frame ,and there is a handle can adjust feeding width

Roll forming device

1.rollers

Gcr15 quenching treat HRC58-60

good hardness for long service time.

2. Each roller has number and with keynotes, it can fix on the shaft stablely

2. Each roller has number and with keynotes, it can fix on the shaft stablely

Transmission device

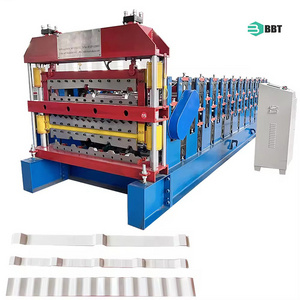

Hydraulic cutting device

1.Adopt double oil cylinder more stable than single oil cylinder

2.Logo press device added

2.Logo press device added

PLC control system

Brand

PLC brand : Delta

Inverter brand: Delta

Low electric part: Schneider

Encoder: Omron

Function:

1.Adopted aviation plugs,easy installation.

2.Full automatic easy operation.

3.Operation language:English(provide customized)

4.National coinsurance,spar parts Brand Siemens and Schneider.

Hydraulic station

7.5kw motor with cooling system for long time using.

Spar parts

Our machine warranty time 2 years and the below spare parts are with the machine send to you free of charge

CE(No.OP180719.CZIDC95)

ISO 9001(No:ZL92090220234630)

Bill of lading showing

we sent many same machines to North America market full of experience-we are the best choice for you.

Hot Searches