- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/50HZ 3Phase(as Customer's Request)

-

Power:

-

25kw

-

Weight:

-

5000 kg

-

Material specification:

-

Galvanized steel,Hot rolled steel, Cold rolled steel

-

Material thickness:

-

0.6-1.1mm

-

Maximum width of steel strip:

-

300mm

-

Punching type:

-

Hydraulic punching

-

Cutting type:

-

Hydraulic cutting

-

Roll material:

-

GCr15 , QuenchHRC58°-62°

-

Driving motor:

-

Frequency conversion motor drive

-

Number of main rollers:

-

14 sets stations

Quick Details

-

Production Capacity:

-

15-25m/min

-

Place of Origin:

-

Shandong, China, Qingdao,China

-

Brand Name:

-

Sunmach, Sunmach

-

Voltage:

-

380V/50HZ 3Phase(as Customer's Request)

-

Power:

-

25kw

-

Weight:

-

5000 kg

-

Material specification:

-

Galvanized steel,Hot rolled steel, Cold rolled steel

-

Material thickness:

-

0.6-1.1mm

-

Maximum width of steel strip:

-

300mm

-

Punching type:

-

Hydraulic punching

-

Cutting type:

-

Hydraulic cutting

-

Roll material:

-

GCr15 , QuenchHRC58°-62°

-

Driving motor:

-

Frequency conversion motor drive

-

Number of main rollers:

-

14 sets stations

Structure and function:

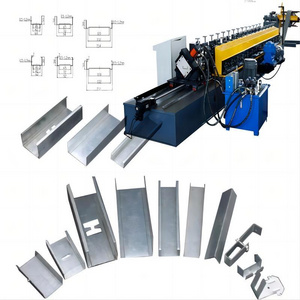

1.The plate has good yiled strength and tensile strength, the cover area is big, it is widely to use in industries, citizen building and new model steel structure building.

2.The line includes simple un-coiler, guide flat, roll forming machine, hydraulic cutter, final product holding frame, hydraulic system, electric control and the others parts, etc.

Uncoiling

—

Forming and

Punching

—

Cutting — Discharging

|

Part 1.Decoiler

|

|

|

|

|

||||

|

Material Specification

|

Galvanized steel,Hot rolled steel, Cold rolled steel

|

|

|

|

||||

|

Width of Material

|

180mm

|

|

|

|

||||

|

Thickness of Material

|

0.6-1.2mm

|

|

|

|

||||

|

Inner Diameter

|

φ430~590mm

|

|

|

|

||||

|

Outer Diameter

|

≤φ1300mm

|

|

|

|

||||

|

Weight of Material

|

≤3 tons

|

|

|

|

||||

|

Part 2.Roll Forming Machine(Forming,Punching,Cutting,Inkjet Printing)

|

|

|

|

|

||||

|

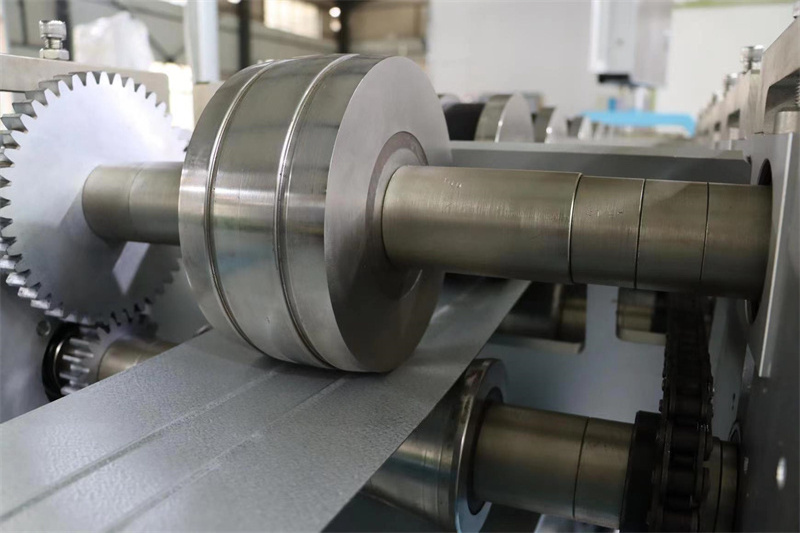

Material of Forming Axle

|

40Cr after tempering and accurate grinding.

|

|

|

|

||||

|

Weight of Machine

|

About 3T

|

|

|

|

||||

|

Roller

|

Imported material

|

|

|

|

||||

|

Drive Type

|

Servo motor(7.5KW)

|

|

|

|

||||

|

Cutting Type

|

Hydraulic cutting

|

|

|

|

||||

15-members professional research and development team

20+ years experience in roll forming

Perfect after-sales service

1500 close cooperation customers

Q:What info you need before you make the proposal?

A:The pipe diameter and thickness range which you need or the profile drawings, material information, your special requirements.

Q: Can you make the machine according to my design or prototype?

A: Yes, we have an experienced team for working out the most suitable design and production plan for the machine that you are going to book with us.

Q:Can I visit you factory to check machines on-site ? What Should I bring when I visit your factory?

A: We are manufacturer, and we welcome customers to visit our factory. For special product design and develop, we request you bring a piece of testing material, you can test on our machines on-site.

Hot Searches