- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Power:

-

Customizable

-

Dimension(L*W*H):

-

Customizable

-

Weight:

-

5000 KG

-

Machinery Function:

-

Making fried French fries and frozen French fries

-

Output product name:

-

French fries potato chips

-

Equipment name:

-

fully automatic potato chips production line

-

Texture of material:

-

High quality SUS304 stainless steel

-

french fries production line Capacity:

-

50-2000kg/h

-

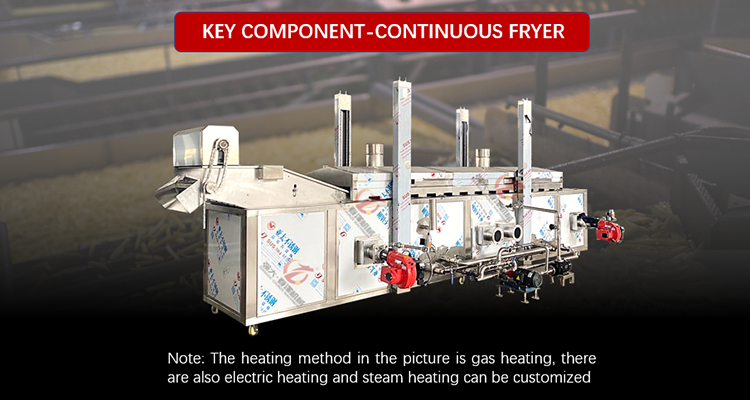

french fries production Heating mode:

-

Electricity, steam, gas, etc

-

french fries production line Effect:

-

Making fried potato chips and frozen potato chips

-

french fries production line Advantage:

-

Safe operating performance temperature

-

Characteristic:

-

Tailored french fries production line

-

Automatic grading:

-

Fully automatic french fries production line

-

Installation services:

-

Engineers can be sent to install on site

-

After-sale service:

-

Fully automatic french fries production line

Quick Details

-

Marketing Type:

-

New Product 2023

-

Brand Name:

-

Qiangda

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

220V/380V

-

Power:

-

Customizable

-

Dimension(L*W*H):

-

Customizable

-

Weight:

-

5000 KG

-

Machinery Function:

-

Making fried French fries and frozen French fries

-

Output product name:

-

French fries potato chips

-

Equipment name:

-

fully automatic potato chips production line

-

Texture of material:

-

High quality SUS304 stainless steel

-

french fries production line Capacity:

-

50-2000kg/h

-

french fries production Heating mode:

-

Electricity, steam, gas, etc

-

french fries production line Effect:

-

Making fried potato chips and frozen potato chips

-

french fries production line Advantage:

-

Safe operating performance temperature

-

Characteristic:

-

Tailored french fries production line

-

Automatic grading:

-

Fully automatic french fries production line

-

Installation services:

-

Engineers can be sent to install on site

-

After-sale service:

-

Fully automatic french fries production line

Fully Automatic French Fries Production Line

Product Description

What potato chip production line?

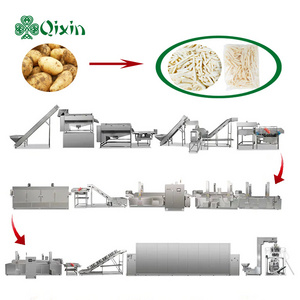

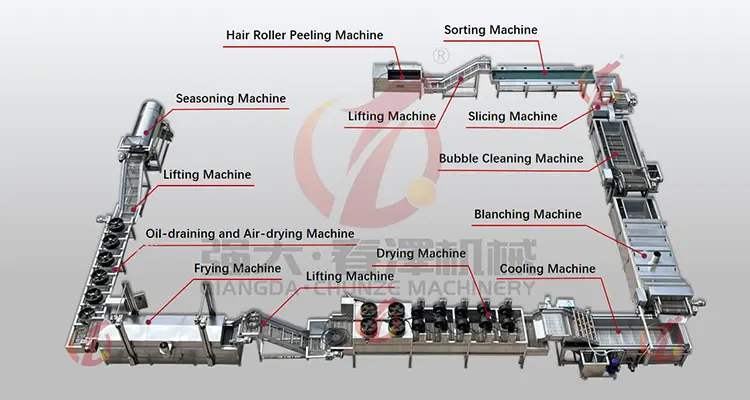

The automatic French fries frying production line is a complete assembly line for the production of fried and frozen French fries.

Including: peeling machine, slicing and slitting machine, bubble cleaning machine, blanching machine, cooler, turnover air dryer,fryer, oil control machine, tumbling seasoning machine, quick freezer, selection belt, conveyor belt and other equipment.After the whole production line processing, we will get fried French fries or frozen French fries, which is suitable for most catering industries.

We can tailor a suitable production line for you according to your requirements and site conditions.

We can tailor a suitable production line for you according to your requirements and site conditions.

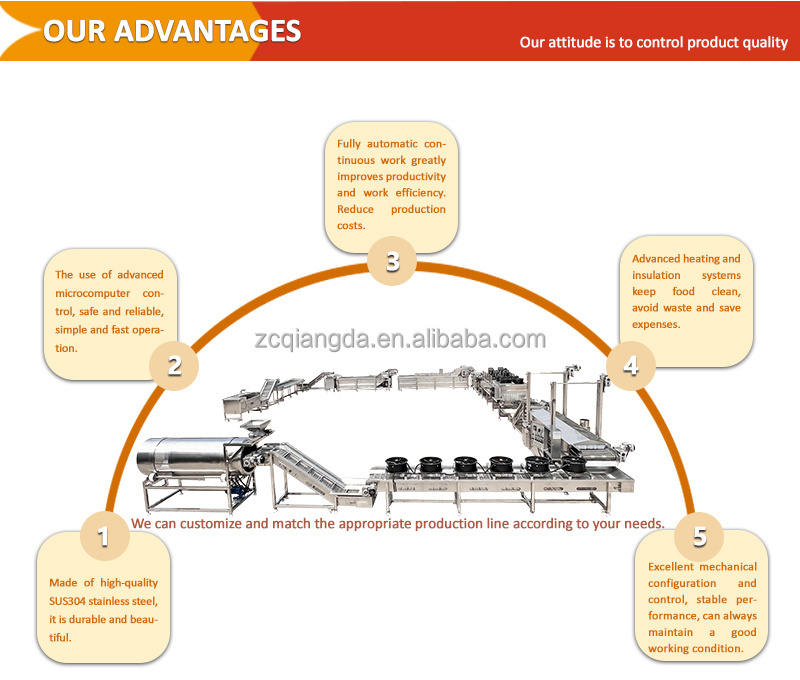

Our advantages:

1.It is made of high-quality SUS304 stainless steel, 4mm thick, durable, rust proof, moisture-proof, corrosion-proof, atmospheric and beautiful appearance, convenient for cleaning and maintenance.

2.Advanced microcomputer control is used in the whole process, which is safe and reliable, and the operation is simple and fast

3.Fully automatic continuous work has greatly improved productivity, strengthened work efficiency, expanded output and effectively reduced production costs.

4.Advanced heating, insulation system and automatic filtration system can keep food clean, avoid waste and save energy

expenditure.

5.Excellent mechanical configuration and control, stable performance, can always maintain good working conditions, can greatly improve product quality, and improve the value and market competitiveness of your products.

2.Advanced microcomputer control is used in the whole process, which is safe and reliable, and the operation is simple and fast

3.Fully automatic continuous work has greatly improved productivity, strengthened work efficiency, expanded output and effectively reduced production costs.

4.Advanced heating, insulation system and automatic filtration system can keep food clean, avoid waste and save energy

expenditure.

5.Excellent mechanical configuration and control, stable performance, can always maintain good working conditions, can greatly improve product quality, and improve the value and market competitiveness of your products.

Product parameters

|

Equipment name

|

Overall dimensions(mm) Customizable

|

|

Peeling and cleaning machine

|

2200*800*1200

|

|

Hoist

|

2500*750*1200

|

|

Manual selection belt

|

4000*1200*900

|

|

Slicer

|

800*1200*1100

|

|

Bubble cleaning machine

|

4000*1250*1500

|

|

Blanching machine

|

5000*1250*1500

|

|

Cooling machine

|

4000*1250*1500

|

|

Turn over air dryer

|

6000*1150*1700

|

|

Frying machine

|

4000*1100*1200

|

|

Oil extractor

|

5000*750*800

|

|

Roller feeder

|

2800*1000*2400

|

Application

Standard packaging for frozen french fries production line / potato chips making machine

Hot Searches