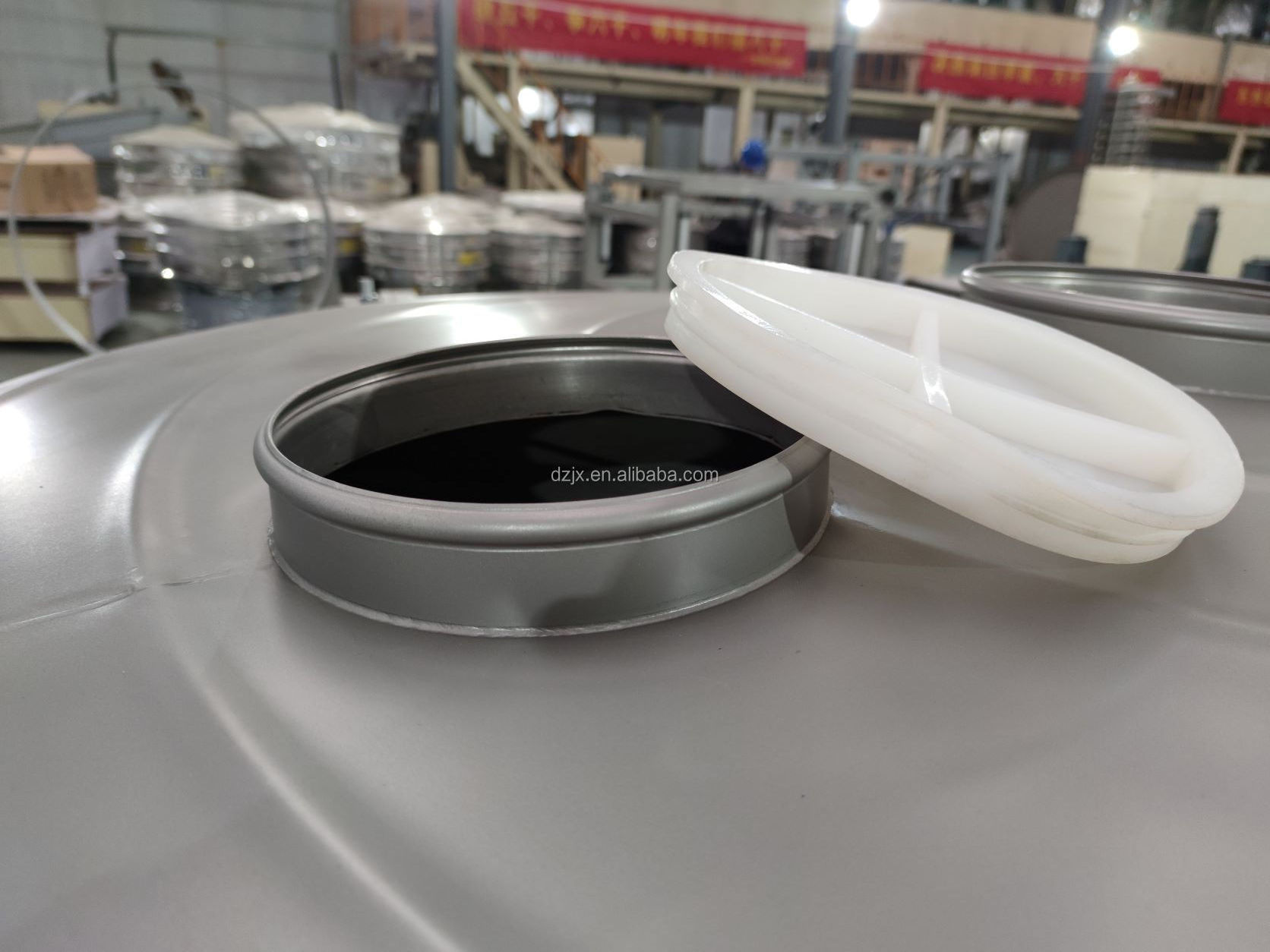

* Observation holes can be added on the cover of the machine according to customer requirements, convenient to check the material

screening at any time.

*

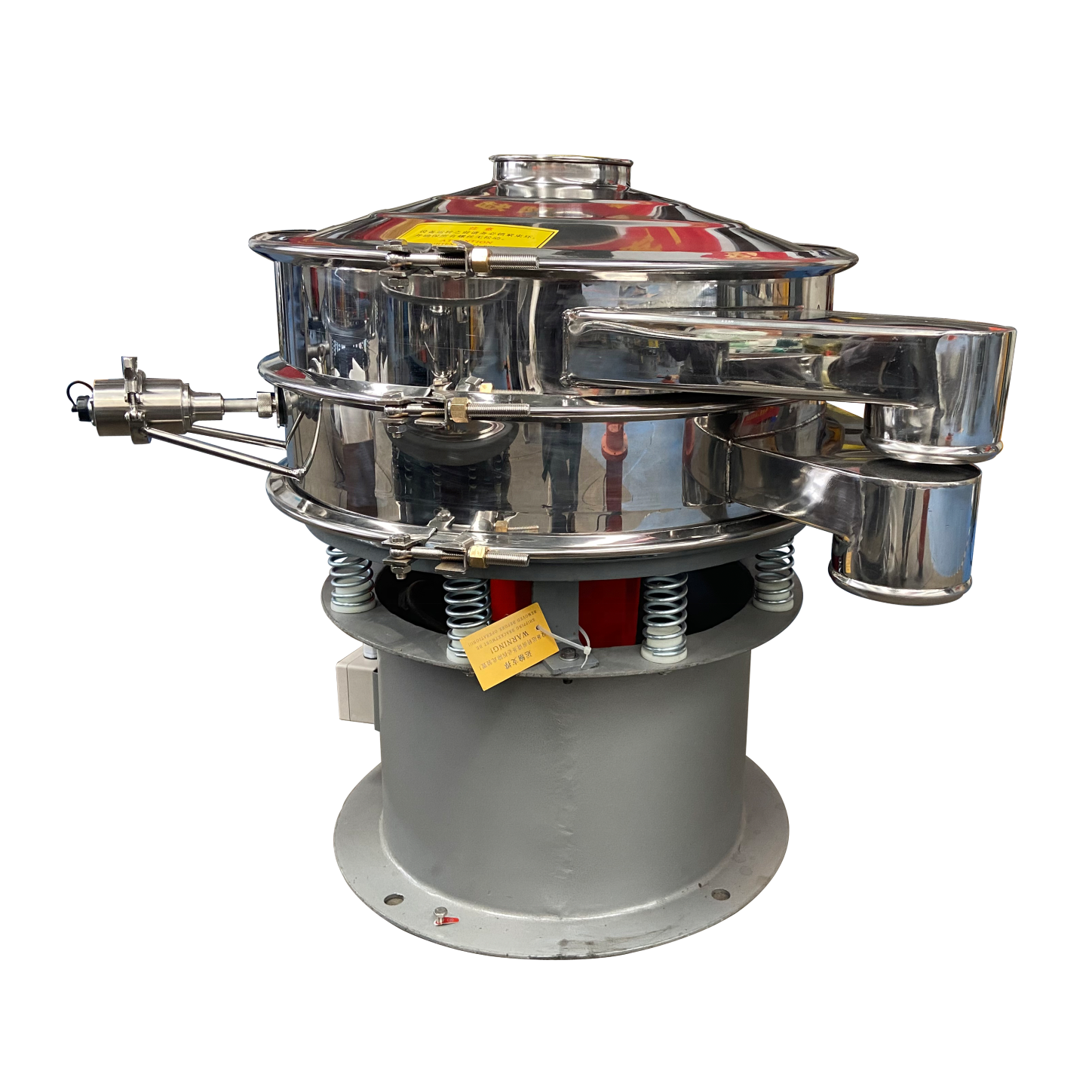

According to customer requirements, the inlet can be designed into various shapes (such as funnel, round, rectangular, etc.)