Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Ejector Force(kN):

-

30 kN

-

Theoretical Shot Volume(cm³):

-

158 cm³

-

Injection Rate (g/s):

-

97 g/s

-

Injection Weight (g):

-

144 g

-

Screw Speed (rpm):

-

220 - 230 rpm

-

Screw diameter (mm):

-

35 mm

-

Distance between Tie Bars:

-

355 *330 mm

-

Weight (KG):

-

2800 kg

-

Place of Origin:

-

Zhejiang, China

-

Open Stroke(mm):

-

320 mm

-

Model Number:

-

HTW90JB

-

Brand Name:

-

HAITAI

-

Power (kW):

-

11 kW

-

Plastic Type:

-

Thermoplastic

-

Automatic:

-

Yes

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

type:

-

Injection molding machine

-

Crew Diameter:

-

30-38mm

-

Screw L/D ratio:

-

23.5-18.5

-

Injection Pressure:

-

230-144 mpa

-

Screw Speed:

-

225 rpm

-

space between tie bar:

-

355 x 330 mm

-

Max mould height:

-

350 mm

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

330mm

-

Distance between Tie Bars(Height)(mm):

-

355mm

-

Ejector Stroke(mm):

-

90 mm

-

Ejector Force(kN):

-

30 kN

-

Theoretical Shot Volume(cm³):

-

158 cm³

-

Injection Rate (g/s):

-

97 g/s

-

Injection Weight (g):

-

144 g

-

Screw Speed (rpm):

-

220 - 230 rpm

-

Screw diameter (mm):

-

35 mm

-

Distance between Tie Bars:

-

355 *330 mm

-

Weight (KG):

-

2800 kg

-

Place of Origin:

-

Zhejiang, China

-

Open Stroke(mm):

-

320 mm

-

Model Number:

-

HTW90JB

-

Brand Name:

-

HAITAI

-

Power (kW):

-

11 kW

-

Plastic Type:

-

Thermoplastic

-

Automatic:

-

Yes

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

type:

-

Injection molding machine

-

Crew Diameter:

-

30-38mm

-

Screw L/D ratio:

-

23.5-18.5

-

Injection Pressure:

-

230-144 mpa

-

Screw Speed:

-

225 rpm

-

space between tie bar:

-

355 x 330 mm

-

Max mould height:

-

350 mm

1. SPECIFICATIONS

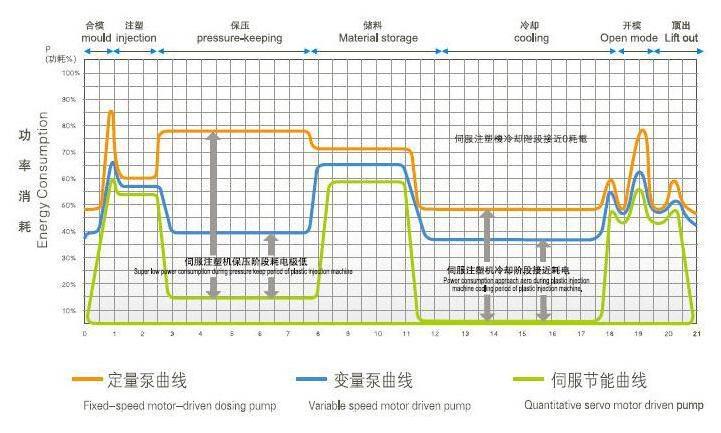

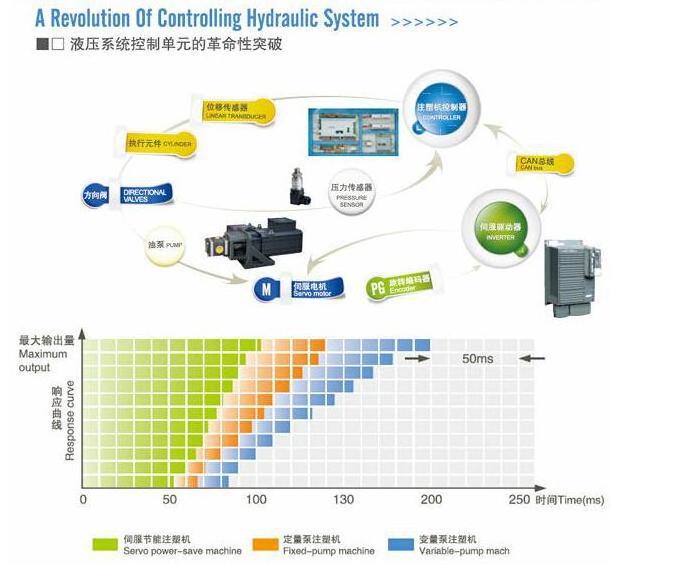

HTW/JB series injection molding machines use a fast response variable pump that has a very high

efficiency and low noise. The variable pump continuously adjust the output pressure and volume of

the pump to match the values called for on the screen for the various parts of the moulding process.

This system contrasts with fixed delivery pumps employing valves to control the required pressure

and volume, and dumping excess oil to tank. This can result in energy savings of 20%-40% compares

with normal machines.

Advantages:

(1) Energy saving

(2) Fast system response and short cycle times

(3) Greatly decreases oil temperature of the system

(4) Smoother mould opening and locking, prolonging the life of the machine and the mould.

(5) The extra oil filtration requirements are met by special imported filter components.

2. TECHNICAL PARAMETERS

|

SPECIFICATION |

HTW90 |

||||

|

|

A |

B |

C |

D |

|

|

INJECTION UNIT |

|

||||

|

Screw diameter |

mm |

30 |

32 |

35 |

38 |

|

Screw L/D ratio |

L/D |

23.5 |

22 |

20.1 |

18.5 |

|

Shot volume(theoretical) |

cm3 |

117 |

133 |

158 |

187 |

|

Injiection weight(ps) |

g |

106 |

121 |

144 |

170 |

|

Injection rate |

g/s |

71 |

81 |

97 |

115 |

|

Injection pressure |

Mpa |

230 |

203 |

170 |

144 |

|

Screw pressure |

rpm |

225 |

|||

|

CLAMPING UNIT |

|||||

|

Clamping force |

kN |

900 |

|||

|

Open stroke |

mm |

320 |

|||

|

Space between tie bars(W×H) |

mm |

355×330 |

|||

|

Max.Mold height |

mm |

350 |

|||

|

Min.Mold height |

mm |

150 |

|||

|

Ejector stroke |

mm |

90 |

|||

|

Ejector force |

kN |

30 |

|||

|

OTHERS |

|||||

|

Max.Pump pressure |

MPa |

16 |

|||

|

Pump motor power |

kW |

11 |

|||

|

Heating power |

kW |

7.55 |

|||

|

Machine dimension(L×W×H) |

m |

3.81×1.19×1.77 |

|||

|

Oiltank cubage |

L |

180 |

|||

|

Machine weight |

t |

2 |

|||

| PLATEN DIMENSIONS | |

| MOULD SPACE DIMENSOINS |