- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

600 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Kerke

-

Voltage:

-

380V 50HZ

-

Dimension(L*W*H):

-

463*345*345

-

Power (kW):

-

90

-

Weight:

-

315 KG

-

Screen changer:

-

Automatic or Manual hydraulic screen changer

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Barrel:

-

45 steel with Bimetal alloy bush

-

Second stage L/D:

-

10:1

-

Screw material:

-

38CrMoAL

-

Shaft:

-

40CrNiMO

-

Screw rotation speed:

-

600Max

-

Gearbox reduce ratio:

-

2.5:1 or 3:1

-

Inventer:

-

Delta

-

Heater:

-

Copper or aluminum heater

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

40:1

-

Screw diameter (mm):

-

93mm

-

Screw Speed (rpm):

-

600 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Kerke

-

Voltage:

-

380V 50HZ

-

Dimension(L*W*H):

-

463*345*345

-

Power (kW):

-

90

-

Weight:

-

315 KG

-

Screen changer:

-

Automatic or Manual hydraulic screen changer

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Barrel:

-

45 steel with Bimetal alloy bush

-

Second stage L/D:

-

10:1

-

Screw material:

-

38CrMoAL

-

Shaft:

-

40CrNiMO

-

Screw rotation speed:

-

600Max

-

Gearbox reduce ratio:

-

2.5:1 or 3:1

-

Inventer:

-

Delta

-

Heater:

-

Copper or aluminum heater

Product details

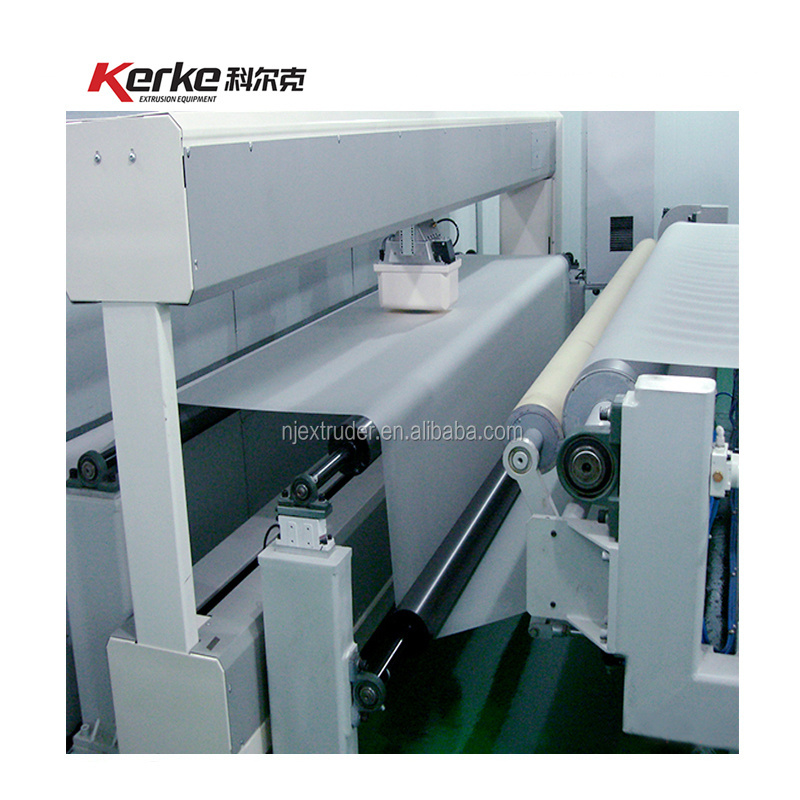

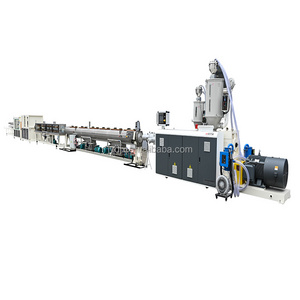

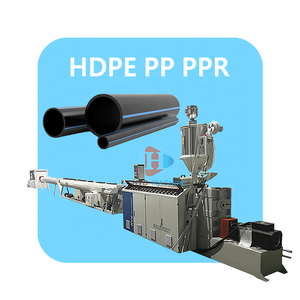

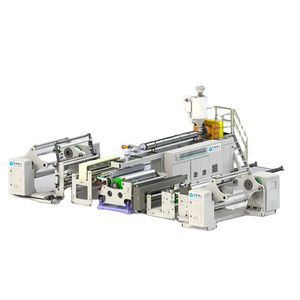

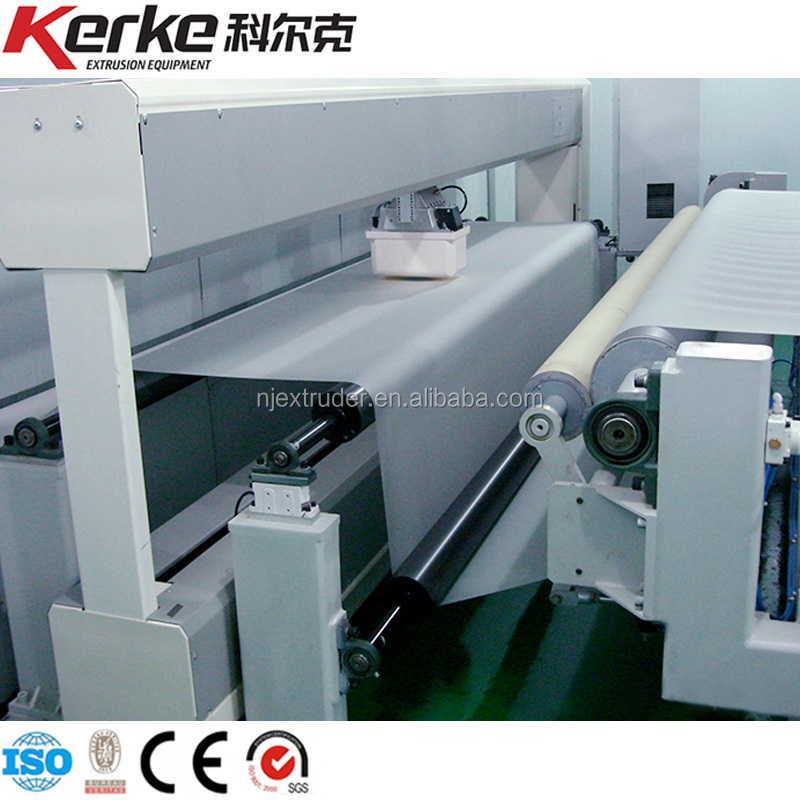

Parallel Twin Screw Extruder PVB Production Line Extrusion Machine.

|

Equipment Model

|

KTE-95B

|

|

Screw Diameter(mm)

|

93

|

|

Screw Length To Diameter Ratio

|

28-60

|

|

Screw Speed(r/min)

|

400/500/600

|

|

Main Motor Power(KW)

|

250/280/315

|

|

Screw Torque(N.m)

|

4202

|

|

Torque Level(T/A³)

|

8.9

|

|

Parameter Table of KTE Series Parallel Twin Screw Extruder Unit

|

|

|

|

|

|

|

|

|

|

|||||||||

|

MOdel

|

Screw diameter (mm)

|

Groove depth ratio (mm)

|

Screw speed (RPM)

|

Drive power (KW)

|

Rated torque (N.m)

|

Center height (mm)

|

Length (mm)

|

Gross weight (kg)

|

Job Capacity (Kg/h)

|

|||||||||

|

KTE-20

|

21.7

|

1.55

|

500

|

4~5.5

|

1X72

|

1000

|

4000

|

800

|

2~15

|

|||||||||

|

KTE-25D

|

25.5

|

1.55

|

500

|

7.5~11

|

2X105

|

1000

|

4500

|

1000

|

5~20

|

|||||||||

|

KTE-36A

|

35.5

|

1.51

|

500

|

15~18.5

|

2X176

|

1000

|

3200

|

1500

|

20~60

|

|||||||||

|

KTE-36B

|

35.5

|

1.51

|

500~600

|

18.5~22

|

2X176

|

1000

|

3200

|

1600

|

20~100

|

|||||||||

|

KTE-36D

|

35.5

|

1.51

|

500~600

|

22~37

|

2X300

|

1000

|

3500

|

1700

|

20~150

|

|||||||||

|

KTE-50A

|

50.5

|

1.55

|

500

|

45~55

|

2X430

|

1000

|

4500

|

2800

|

80~150

|

|||||||||

|

KTE-50B

|

50.5

|

1.55

|

500~600

|

55~75

|

2X600

|

1000

|

4500

|

2800

|

80~200

|

|||||||||

|

KTE-50D

|

50.5

|

1.55

|

300~800

|

75~90

|

2X656

|

1000

|

4800

|

2800

|

100~300

|

|||||||||

|

KTE-52B

|

51.4

|

1.58

|

500~600

|

55~75

|

2X620

|

1000

|

4500

|

3000

|

80~200

|

|||||||||

|

KTE-52D

|

51.4

|

1.58

|

500~600

|

75~110

|

2X656

|

1000

|

4800

|

3000

|

100~400

|

|||||||||

|

KTE--60A

|

59.4

|

1.37

|

500

|

75~90

|

2X720

|

1000

|

5400

|

4000

|

100~350

|

|||||||||

|

KTE--60B

|

59.4

|

1.37

|

500~600

|

75~90

|

2X750

|

1000

|

5400

|

5000

|

200~450

|

|||||||||

|

KTE--65A

|

62.4

|

1.55

|

500

|

75~90

|

2X720

|

1000

|

5400

|

5000

|

100~350

|

|||||||||

|

KTE--65B

|

62.4

|

1.55

|

500~600

|

75~90

|

2X750

|

1000

|

5400

|

5000

|

200~450

|

|||||||||

|

KTE--65D

|

62.4

|

1.55

|

300~800

|

90~132

|

2X790

|

1000

|

5800

|

5000

|

350~600

|

|||||||||

|

KTE--70B

|

69

|

1.44

|

500~600

|

110~132

|

2X1280

|

1000

|

6400

|

6500

|

300~500

|

|||||||||

|

KTE--75A

|

71

|

1.51

|

300~800

|

110~132

|

2X1050

|

1000

|

6400

|

6000

|

300~500

|

|||||||||

|

KTE--75B

|

71

|

1.51

|

500~600

|

132~160

|

2X1280

|

1000

|

6400

|

6400

|

300~800

|

|||||||||

|

KTE--75D

|

71

|

1.51

|

300~800

|

160~250

|

2X1320

|

1000

|

6800

|

7000

|

500~1000

|

|||||||||

|

KTE--85B

|

85

|

1.54

|

500~600

|

200~250

|

2X1910

|

1100

|

7000

|

8000

|

550~1000

|

|||||||||

|

KTE--85D

|

85

|

1.54

|

500~800

|

250~315

|

2X2400

|

1100

|

7000

|

10000

|

800~1500

|

|||||||||

|

KTE--95B

|

93

|

1.52

|

500~600

|

280~315

|

2X3000

|

1100

|

7800

|

12000

|

800~1500

|

|||||||||

|

KTE--95D

|

93

|

1.51

|

500~800

|

315~750

|

2X4500

|

1100

|

7800

|

15000

|

1000~2000

|

|||||||||

|

KTE--135B

|

135

|

1.55

|

500~600

|

500~750

|

2X4800

|

1200

|

9000

|

30000

|

1500~3000

|

|||||||||

|

KTE--135D

|

135

|

1.55

|

500~800

|

750~1800

|

2X10800

|

1200

|

9000

|

34000

|

1500~4000

|

|||||||||

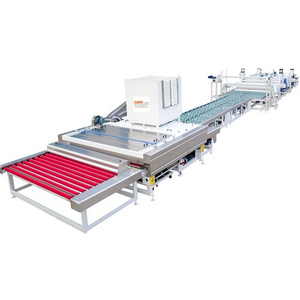

Product display

Exhibition

Sale Service

Before-Sale

1. Introduce products and Applications details

2. Recommend suitable solution

3. Provide with reference in formation

4. Offer lab for test

In production

1. Provide with layout and engineering conditions

2. Inform the project processing status

3. Offer other documents

After-sale

1. Provide with installation, commissioning and training

2. Offer spare parts

3. Provide with necessary technical support for new application

Factory strength

Nanjing Kerke Extrusion Equipment Co., Ltd

is a comprehensive manufacturing and trading company in China. our company is a professional manufacturer of high quality pelletizing extruders for coloring /dyeing and masterbatch production, as well as plastic modification and compounding,plastic recycling. Innovative machines are built as per the concept of durability, high efficiency and economical power consumption.

We carry out a strict quality management system in accordance with CE requirements. There are over 100 styles of extruder and extruder spare parts and we also can customize for customers' various requirement for extruder spare parts. Our annual production capacity is 200 sets plastic extruder in domestic country! And we also have OEM ability in pelletizing plastic extruder industry in consistence with specific requirement from both national and international customers.

Moreover, we are pleased to introduce our company as one of the leading exporters of parallel twin screw extruder in China.

Our machine types:

1. Co-Rotating Parallel Twin Screw Pelletizing Extruders

2. Single Screw Pelletizing Extruders

3. Die Face Cut (Air Cooling) Pelletizing Extruders

4. Double Stage / Double Degassing Recycling Extruders

5. Crushers, Mixers, Storage Tanks, Vibrators, Granulators, Blowers

6. Extruder spare parts

If you are interested in some of our products, please feel free to visit our website or contact us for more information and pictures. We are looking forward to establishing long-lasting business relationships with you in the near future.

Product packaging

Certifications

Hot Searches