- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

After-sales Service Provided:

-

Online support, Engineers available to service machinery overseas

-

Product name:

-

MICC high quality cartridge Heater

-

Application:

-

Industry Heating Process

-

Material:

-

SS304

-

Tube Diametre:

-

3mm-30mm

-

Insulation Material:

-

High purity mgo powder

-

Heating wire:

-

NICR

-

Lead way:

-

inside or external

-

Normal wire length:

-

500mm or Customized

-

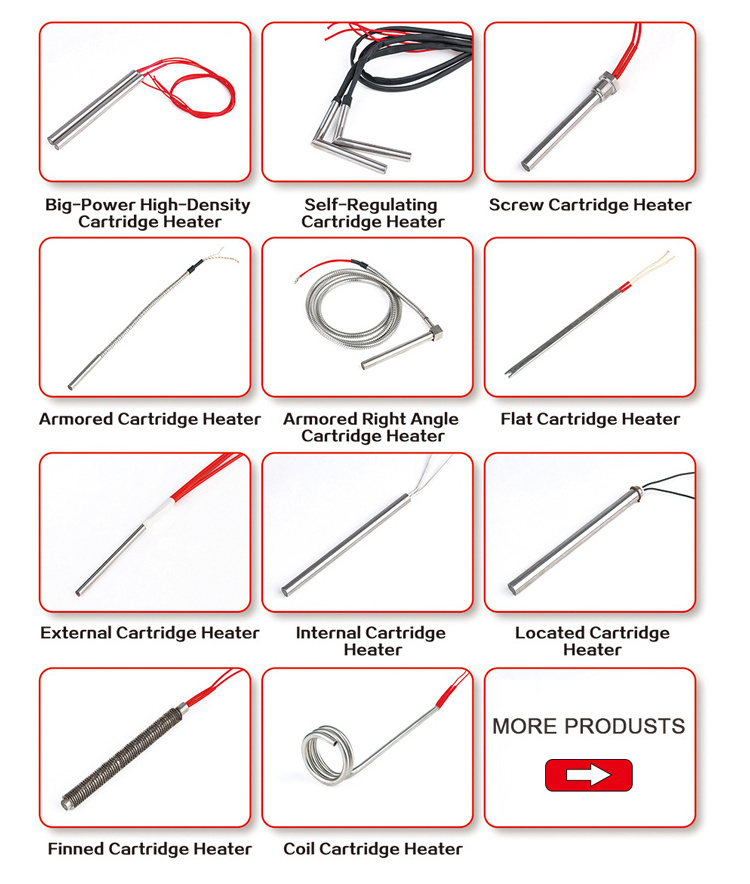

Types:

-

High power density /middle power density

-

Certification:

-

CE ROHS

Quick Details

-

Type:

-

high /medium density

-

Power Source:

-

Electric

-

Voltage:

-

Customized

-

Place of Origin:

-

Jiangsu, China

-

After-sales Service Provided:

-

Online support, Engineers available to service machinery overseas

-

Product name:

-

MICC high quality cartridge Heater

-

Application:

-

Industry Heating Process

-

Material:

-

SS304

-

Tube Diametre:

-

3mm-30mm

-

Insulation Material:

-

High purity mgo powder

-

Heating wire:

-

NICR

-

Lead way:

-

inside or external

-

Normal wire length:

-

500mm or Customized

-

Types:

-

High power density /middle power density

-

Certification:

-

CE ROHS

Description

Electric heater cartridge is a piece of equipment, made of MgO powder or MgO tube, ceramic cap, resistance wire(NiCr2080),High temperature leads, seamless stainless steel sheath(304,321,316,800,840). usually in tube form,

that is used in heating applications by way of insertion into metal blocks via a series of drilled holes. Cartridge heaters are manufactured in two basic forms - high density and low density.

High density cartridge heaters are used to heat plastic injection moulds, dies, platens and so forth, whereas low density cartridge heaters are more suitable for packing machinery, heat sealing, labelling machines and hot stamping applications.

Application

· Injection moulding - Internal heating of nozzles

· Hot runner systems - Heating of manifolds

· Packaging industry - Heating of cutting bars

· Packaging industry - Heating of hot stamps

· Laboratories - Heating of analytical equipment

· Medical: Dialysis, Sterilization, Blood Analyzer, Nebulizer, Blood/Fluid Warmer, Temperature Therapy

· Telecommunications: Deicing, Enclosure Heater

· Transportation: Oil/Block Heater, Aircraft Coffee Pot Heaters,

· Food Service: Steamers, Dish Washers,

· Industrial: Packaging Equipment, Hole Punches, Hot Stamp.

Technical data

|

Industrial heater |

Immersion cartridge water heater with thermocouple |

|

Resistance heating wire |

NiCr 80/20 wire |

|

Sheath |

stainless steel 304,321,316, Incoloy 800, Incoloy 840 |

|

Maximum temperature |

800 degree Celsius |

|

Wattage Tolerance |

+5%, -10% |

|

Resistance tolerance |

+10%, -5% |

|

Voltages available |

380V,240V, 220V,110V,36V,24V or 12V |

|

Length tolerance |

±1 mm |

|

Diameter tolerance |

-0.02mm |

|

Standard Cold Zone |

5-10mm |

|

Delivery time |

7-10 working days |

|

Insulation resistance (cold) |

≥ 500 MΩ |

|

Maximum leakage current (cold) |

≤ 0.5 mA |

|

Thermocouple Location |

type J |

|

type K

|

|

Products Show

Advantage

1. Low MOQ : It can meet your promotional business very well.

2. OEM Accepted : We can produce any your design as long as you provide us the drawing.

3. Good Service : We treat clients as friend.

4. Good Quality :We have strict quality control system .Good reputation in the foreigner market

5. Fast & Cheap Delivery : We have big discount from forwarder (Long Contract)

Order Guide

Check below for more information on placing

|

1. Inquiry-Professional and accurate quotation. |

|

2. Confirm the price, trade term, lead time, artwork, payment term etc. |

|

3. MICC sales send the Proforma Invoice with MICC seal. |

|

4. Customer arranges the payment for deposit and sends us bank slip. |

|

5.Initial Production step-Inform the clients that we have got the payment. And will make the samples according to your request, send you photos or Samples to get your approval. After approval, we inform that we will arrange the production & inform the estimated time. |

|

6. Middle Production-send photos to show the production line which you can see your products in . Confirm the estimated delivery time again. |

|

7. End Production-Mass production products photos. |

|

8. Clients make payment for balance and MICC ships the goods. Inform the tracking number and check the status for clients. |

|

9. The order is finished perfectly when you receive the goods and get satisfied with them . |

|

10. Feedback to MICC about Quality , Service, Market Feedback & Suggestion. And we will do better . |